Multiwall carbon nanotube-polysilane composite material and preparation method thereof

A technology of multi-walled carbon nanotubes and composite materials, applied in the field of carbon nanotube-polysilane composite materials and their preparation, can solve the problems of large specific surface energy of carbon nanotubes, poor dispersibility, weak organic binding ability and the like, and achieve electrical conductivity. The effect of improving the rate, easy film formation, and improving the binding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0020] Embodiment 1: This embodiment is a multi-walled carbon nanotube-polysilane composite material prepared from silanized multi-walled carbon nanotubes, dichlorosilane derivatives, organic solvents and alkali metals.

[0021] The mass ratio of the silanized multi-walled carbon nanotubes described in the present embodiment to the alkali metal is 1: (1.2 ~ 50); the ratio of the mass of the silanized multi-walled carbon nanotubes described in the present embodiment to the volume of the organic solvent is 1g: (200mL~1000mL); the mass ratio of the silanized multi-walled carbon nanotubes described in this embodiment to the dichlorosilane derivative is 1:(10~100).

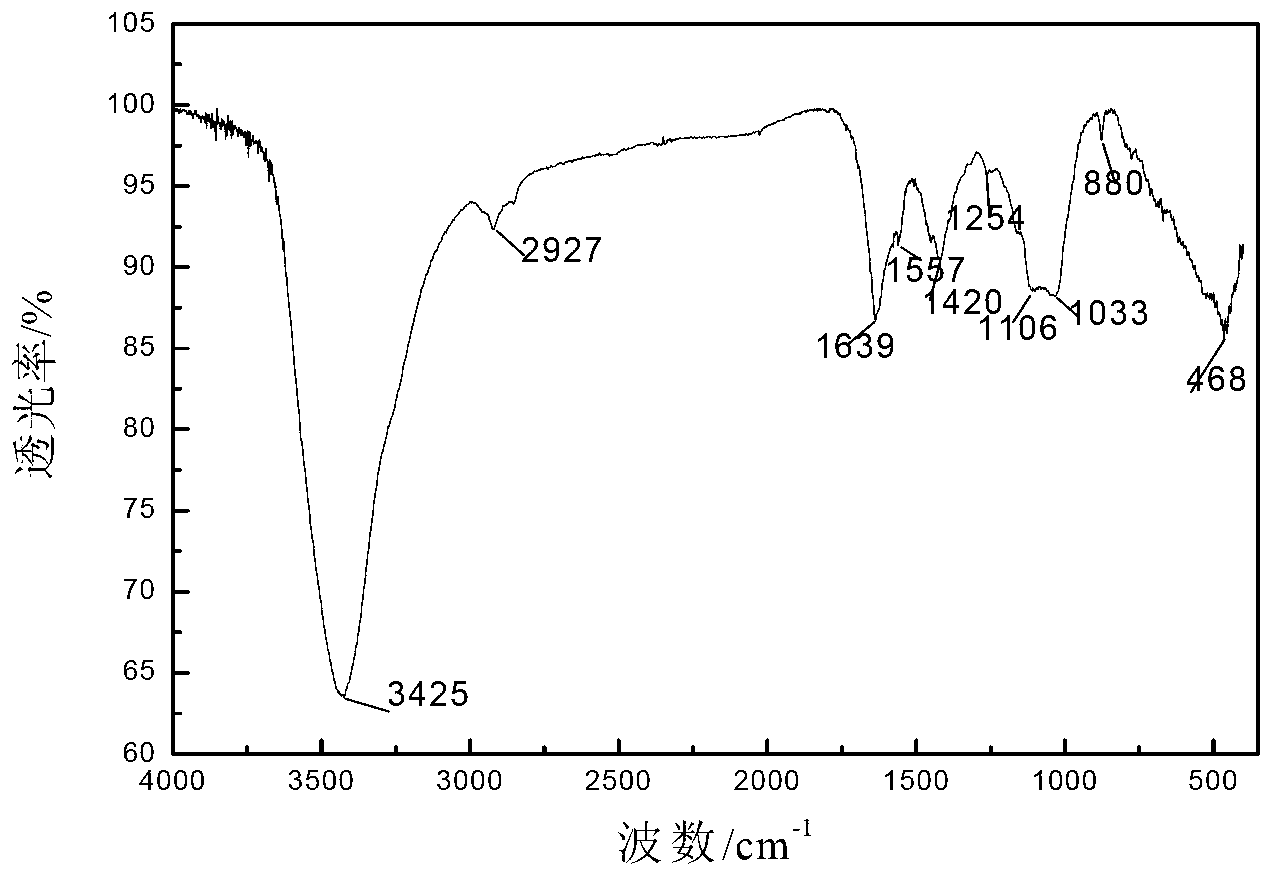

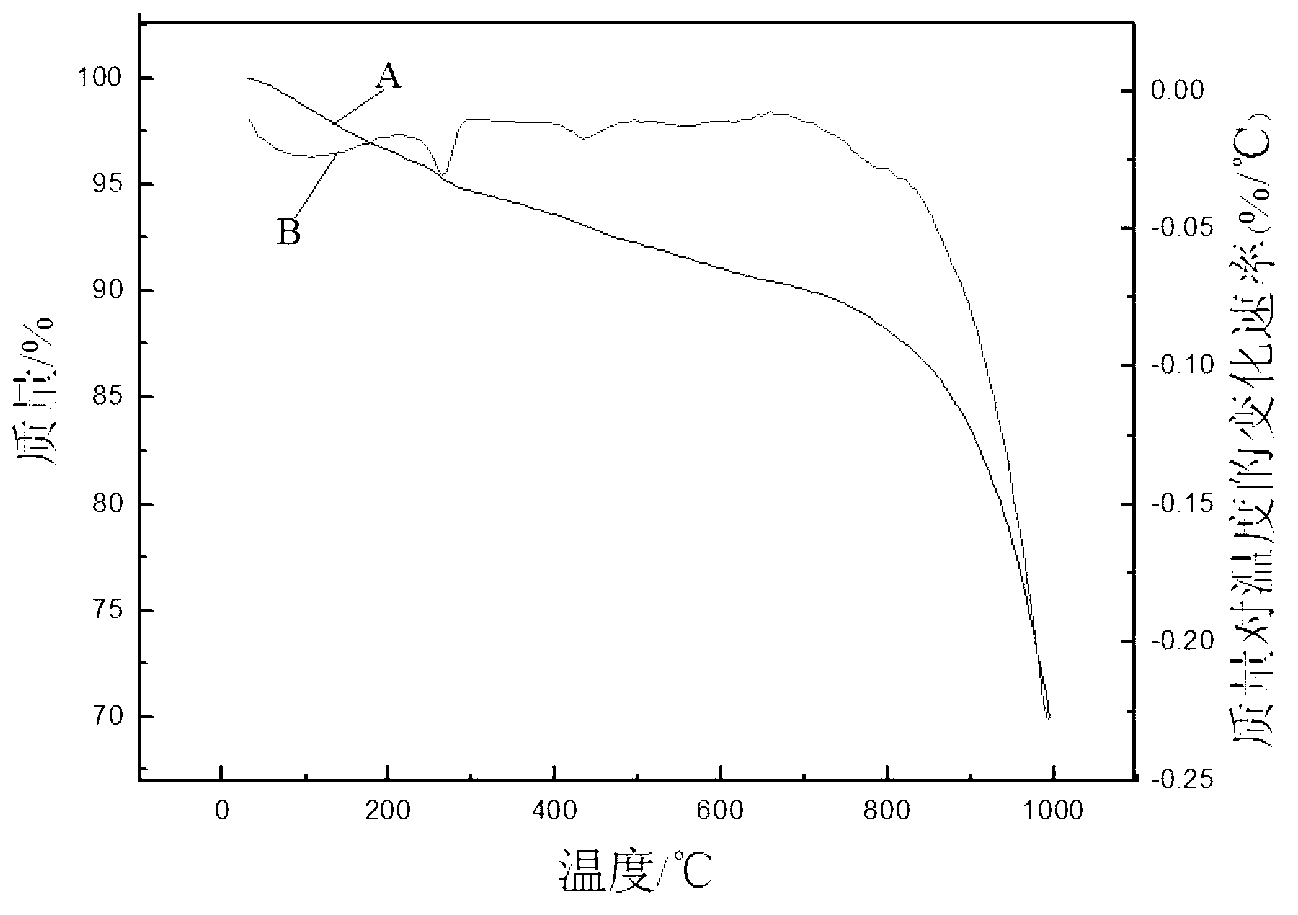

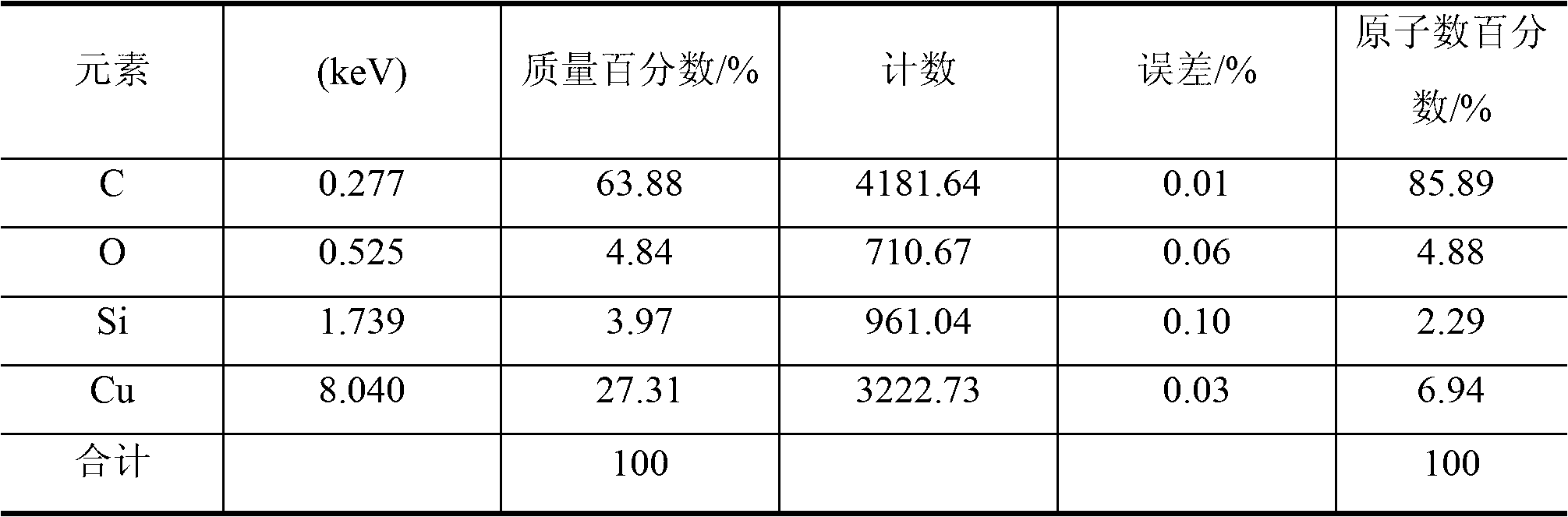

[0022] The multi-walled carbon nanotube-polysilane composite material described in this embodiment is covalently bonded to the multi-walled carbon nanotube grafted polysilane to obtain a multi-walled carbon nanotube-polysilane composite material, which is compatible with the existing carbon nanotube In comparison, the ...

specific Embodiment approach 2

[0024] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the silanized multi-walled carbon nanotubes are prepared according to the following steps:

[0025]1. Purification: First, calcine the multi-walled carbon nanotubes at a temperature of 480°C~520°C for 20min~40min, and pour the calcined multiwalled carbon nanotubes into hydrochloric acid with a concentration of 4mol / L~6mol / L. And stir at a stirring speed of 600r / min~1000r / min for 30min~50min, then ultrasonically oscillate for 5h~7h with the help of ultrasonic waves with a frequency of 30KHz~50KHz, and then filter with a mixed fiber microporous membrane with a pore size of 0.22μm , the obtained solid filtered product was washed with distilled water until the pH of the filtrate = 7±0.1, and then the washed solid was placed in a vacuum drying oven and dried at a temperature of 40°C~60°C for 20h~28h to obtain a dry The final product is ground to obtain purified multi-walled carbon nanotubes;

[00...

specific Embodiment approach 3

[0036] Specific embodiment three: the difference between this embodiment and specific embodiment two is: the phenol derivative described in step four is hydroquinone or p-aminophenol; the acid-binding agent described in step four is pyridine or triethyl Amine; the cleaning agent described in step four is anhydrous acetone. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com