Feruloyl esterase production strain and method for producing feruloyl esterase by using same

A ferulic acid esterase and ferulic acid technology, applied in the field of bioengineering, can solve problems such as complex operation, ferulic esterase extraction method needs to be improved, and industrial production limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

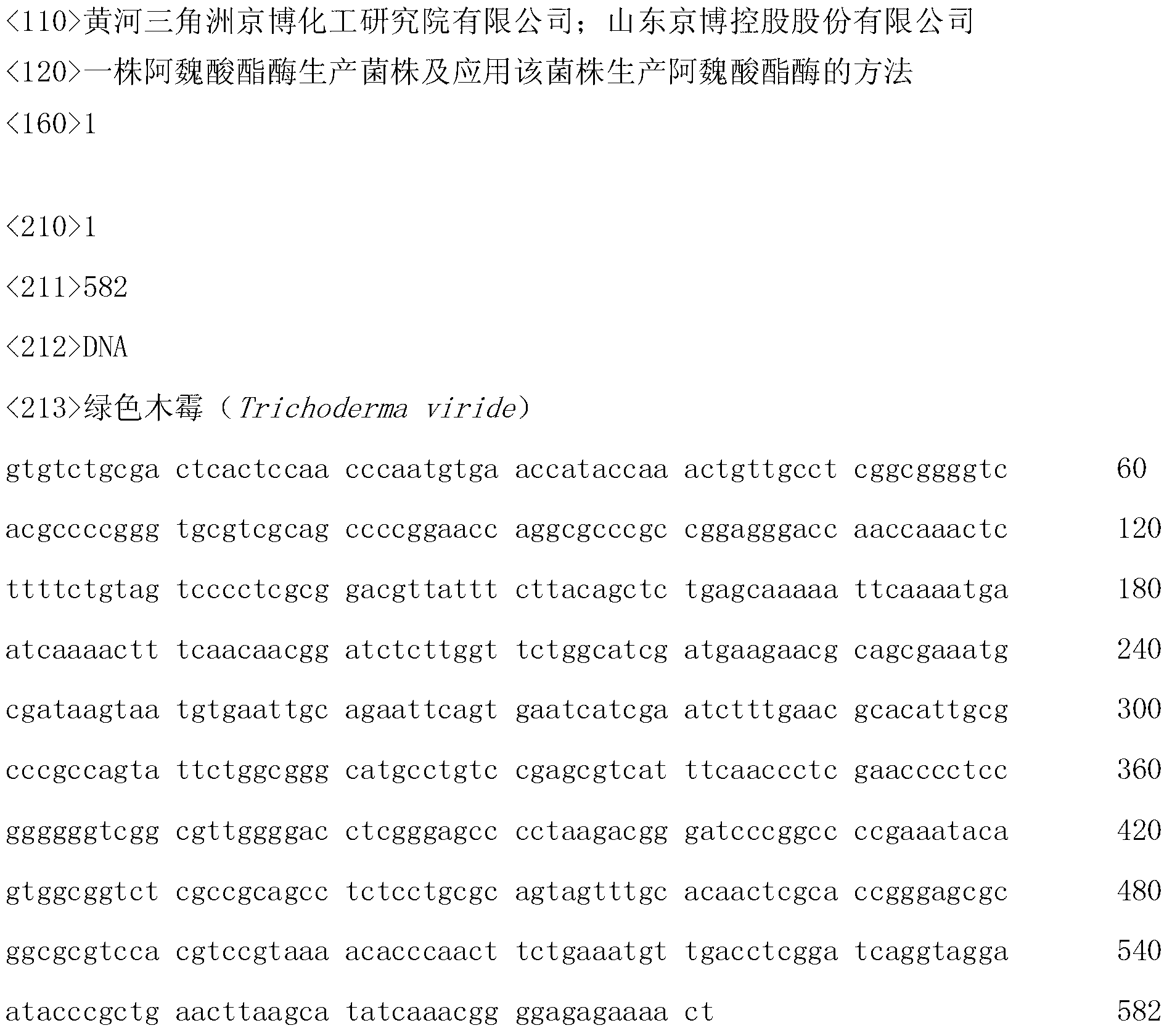

Image

Examples

Embodiment 1

[0067] (1) Activation of strains: move the strains on the slant of the test tube stored on PDA medium at 4°C to room temperature (20-25°C) for activation for 4 hours;

[0068] (2) Preparation of liquid seeds: Use 10mL of sterilized distilled water to make a suspension of the activated test tube slant strains on the aseptic operating table, and wash them into the sterile seed culture under aseptic conditions. In the Erlenmeyer flask of the base, one test tube strain was inoculated into one Erlenmeyer flask, the pH value was natural, the culture temperature was 24°C, the shaker speed was 200r / min, and the culture time was 48h;

[0069] The composition of the seed medium, by weight (w / w): 2% sucrose, 0.2% yeast extract powder, 0.05% magnesium sulfate, 0.025% potassium dihydrogen phosphate, add water to 1000mL; sterilization conditions are 121°C, 0.15Mpa Sterilize for 20 minutes;

[0070] (3) Fermentation and regulation process: Inoculate liquid seeds with 10% (v / v) inoculum into...

Embodiment 2

[0074] (1) Activation of strains: move the strains on the slant of the test tube stored on PDA medium at 4°C to room temperature (20-25°C) for activation for 4 hours;

[0075] (2) Preparation of liquid seeds: Use 10mL of sterilized distilled water to make a suspension of the activated test tube slant strains on the aseptic operating table, and wash them into the sterile seed culture under aseptic conditions. In the Erlenmeyer flask of the base, one test tube strain was inoculated into one Erlenmeyer flask, the pH value was natural, the culture temperature was 24°C, the shaker speed was 200r / min, and the culture time was 48h;

[0076] The composition (w / w) of the seed medium is: by weight (w / w): 2% sucrose, 0.6% yeast extract powder, 0.05% magnesium sulfate, 0.025% potassium dihydrogen phosphate, add water to 1000mL; sterilization conditions Sterilize at 121°C, 0.15Mpa for 20min;

[0077] (3) Fermentation and regulation process: Inoculate the liquid seeds with 5% (v / v) inoculu...

Embodiment 3

[0081] (1) Activation of strains: move the strains on the slant of the test tube stored on PDA medium at 4°C to room temperature (20-25°C) for activation for 4 hours;

[0082](2) Preparation of liquid seeds: Use 10mL of sterilized distilled water to make a suspension of the activated test tube slant strains on the aseptic operating table, and wash them into the sterile seed culture under aseptic conditions. In the Erlenmeyer flask of the base, one test tube strain was inoculated into one Erlenmeyer flask, the pH value was natural, the culture temperature was 24°C, the shaker speed was 200r / min, and the culture time was 48h;

[0083] The composition of the seed medium, by weight (w / w): 2% sucrose, 0.2% yeast extract powder, 0.05% magnesium sulfate, 0.025% potassium dihydrogen phosphate, add water to 1000mL; sterilization conditions are 121°C, 0.15Mpa Sterilize for 20 minutes;

[0084] (3) Fermentation and regulation process: Inoculate the liquid seeds with 5% (v / v) inoculum in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com