High water retention microbe medium and preparation method

A microbial culture medium and water retention technology, applied in the direction of fungi, bacteria, etc., can solve the problems of easy crystallization or cracking, prolonging the culture time of microorganisms, and dehydration of the medium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

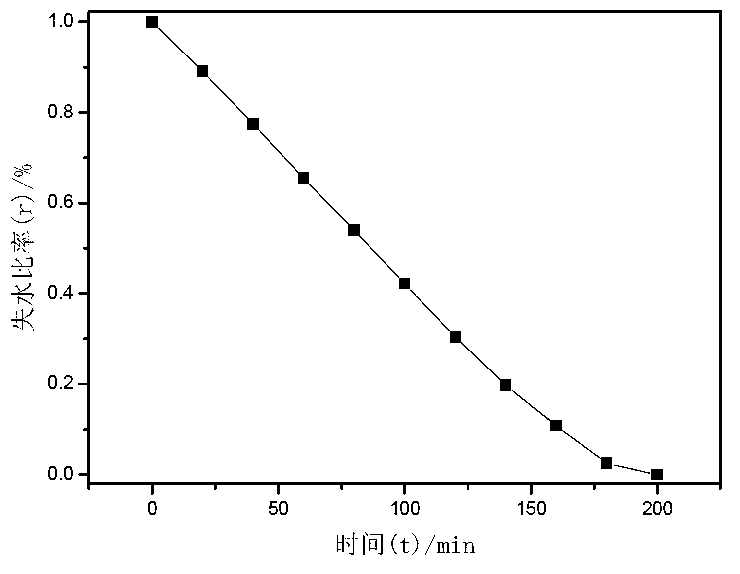

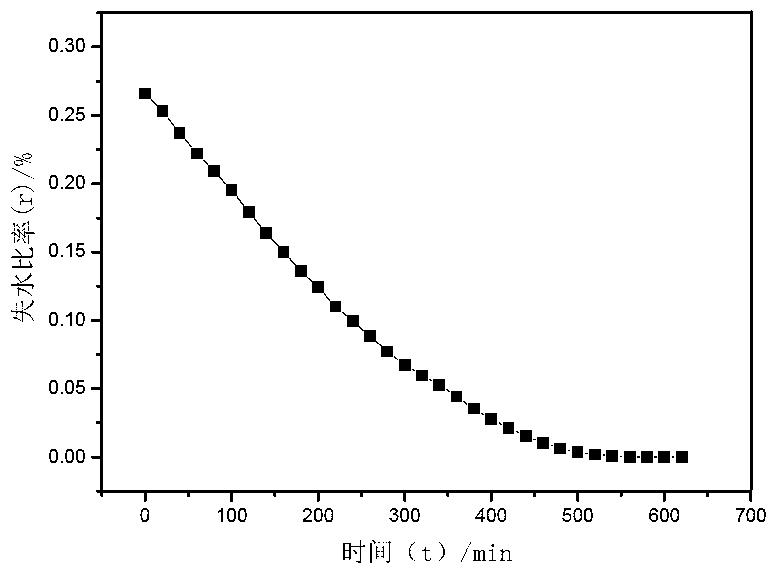

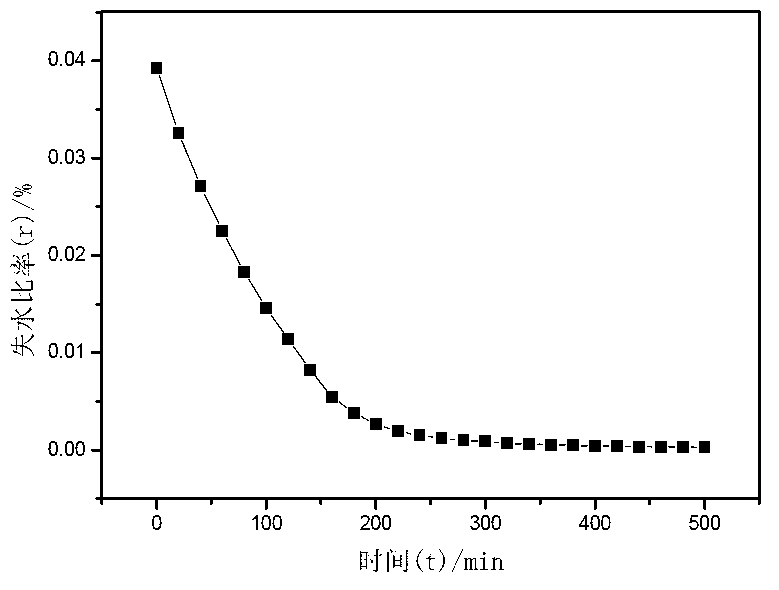

Image

Examples

preparation example Construction

[0147] The steps of the preparation method of the microbial culture medium with high water retention are as follows:

[0148] 1) Preparation of super absorbent resin

[0149] (1) First dissolve the alkali with a mass ratio of 1:10~1:1 to the monomer in water in an ice-water bath (or do not add alkali when the main monomer is a non-acidic monomer); then slowly drop into the monomer It is configured into a monomer solution with a concentration of 5-90% (this monomer can be one kind, or it can be a co-monomer composed of a hydrophobic monomer with a mass ratio of 0.01%-1% of the main monomer) , keep the system at a certain temperature, do not make the local temperature too high; then add a cross-linking agent with a mass ratio of 1:10000~1:10 and an initiator with a mass ratio of 1:10000~1:10 to dissolve it In solution;

[0150] (2) Put the reaction vessel in a water bath at 70-90°C and heat it for 0.5-5 minutes while stirring magnetically, or put the reaction vessel in a micro...

Embodiment 1

[0169] 1) Preparation of super absorbent resin

[0170] ①First, dissolve sodium hydroxide with a mass ratio of 3:10 to acrylic acid in water in an ice-water bath; then slowly drop in acrylic acid to make it into an acrylic acid solution with a concentration of 30%, keep the system at a certain temperature, do not use The local temperature is too high; then add N, N`-methylenebisacrylamide with a mass ratio of 1:1000 to acrylic acid and potassium persulfate at 1:1000, and dissolve them in the solution;

[0171] ② Put the reaction vessel into a water bath at 70°C and heat for 5 minutes while magnetically stirring. Or put the reaction vessel into the microwave oven for 6 minutes and let it rotate to heat evenly. Take it out immediately after the reaction is over, then place it at room temperature, and slowly lower the system temperature to room temperature;

[0172] ③ Put it in a 45°C oven for 6 hours;

[0173] ④ Raise the temperature to 85°C, continue the reaction for 30 minu...

Embodiment 2

[0179] 1) Preparation of super absorbent resin

[0180]①First, dissolve sodium hydroxide with a mass ratio of 2:5 to methacrylic acid in water in an ice-water bath; then slowly drop methacrylic acid to make it into a methacrylic acid solution with a concentration of 40%, keeping the system at a certain In the temperature, do not make the local temperature too high; then add polyethylene glycol bismaleate and potassium persulfate of 1:500 with the mass ratio of methacrylic acid, and dissolve it in the solution;

[0181] ② Put the reaction vessel into a water bath at 75°C and heat for 4 minutes while magnetically stirring. Or put the reaction vessel into the microwave oven for 5 minutes and let it rotate to heat evenly. Take it out immediately after the reaction is over, then place it at room temperature, and slowly lower the system temperature to room temperature;

[0182] ③ Put it in an oven at 50°C for 5 hours;

[0183] ④ Raise the temperature to 87°C, continue the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com