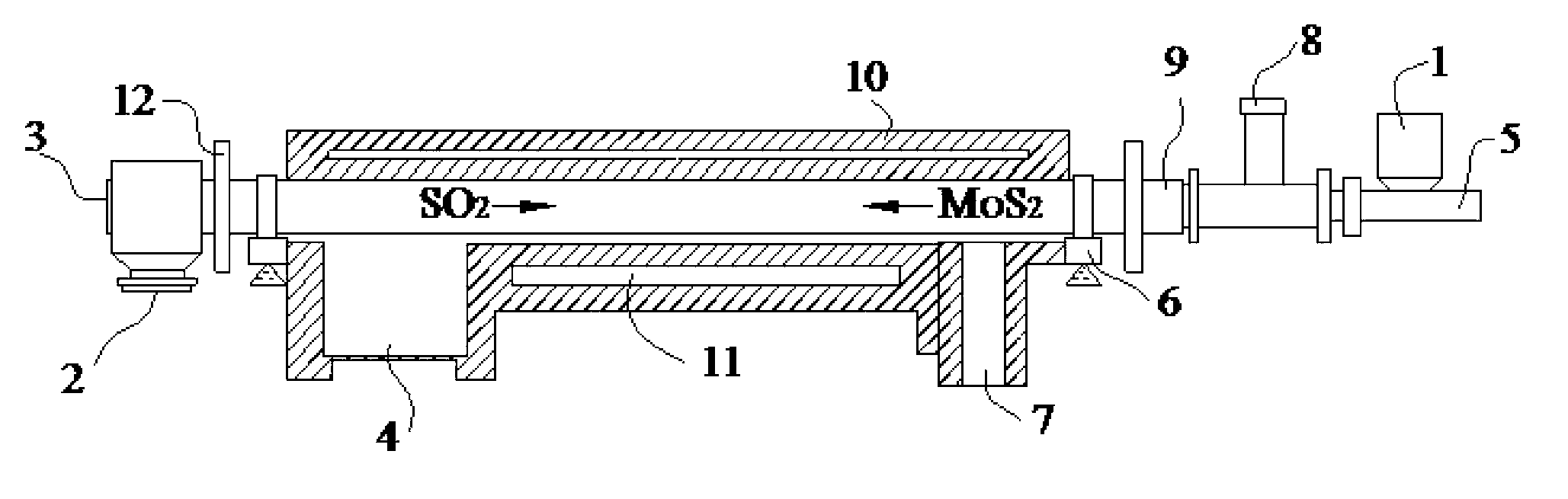

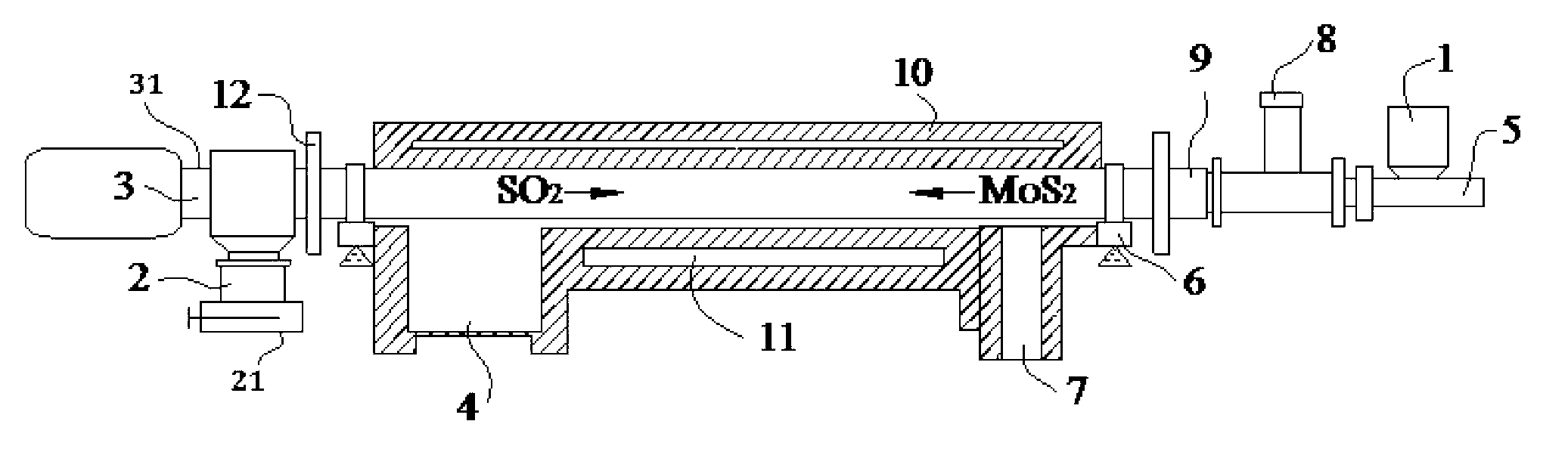

Device and technology for oxygen-enriched roasting of molybdenum sulfide concentrate

An oxygen-enriched roasting and molybdenum sulfide technology is applied in the field of roasting equipment and processes for molybdenum sulfide concentrate to achieve the effects of reducing operation difficulty, easy control and stabilizing product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Oxygen-enriched air is used instead of ordinary air as the oxidant for oxidation roasting to produce industrial molybdenum oxide. Oxygen-enriched air can be produced with industrial oxygen or with an oxygen generator.

[0023] A small industrial roasting rotary kiln (Φ1000mm×20000mm) exhaust gas (mainly composed of nitrogen, oxygen, and sulfur dioxide) emission per hour is 11000m 3 Around, the temperature of the exhaust gas is about 350°C~400°C (623k~673k).

[0024] Heat taken away (kJ / h) Q=Cp×m×Δk=Cp×ρ×V×(k 2 -k 1 )

[0025] Cp—constant pressure hot melt, 1.009kJ / kg k

[0026] m-quantity, kg

[0027] Δk-temperature difference, k

[0028] ρ—density, 1.293kg / m 3

[0029] V—volume, m 3

[0030] Therefore, the heat taken away by an industrial rotary kiln per hour (the specific heat capacity of the exhaust gas is approximately calculated according to the specific heat capacity of the air):

[0031] Q 1 =1.009kJ / kg·k×1.293kg / m 3 ×11000m 3 ×(623k-293k)=4.74×10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com