Process for producing schottky diode

A technology of Schottky diode and preparation process, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc. It can solve problems such as difficult embedding of Schottky diode technology and inability to manufacture Schottky diode, so as to increase complexity , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with specific drawings and embodiments.

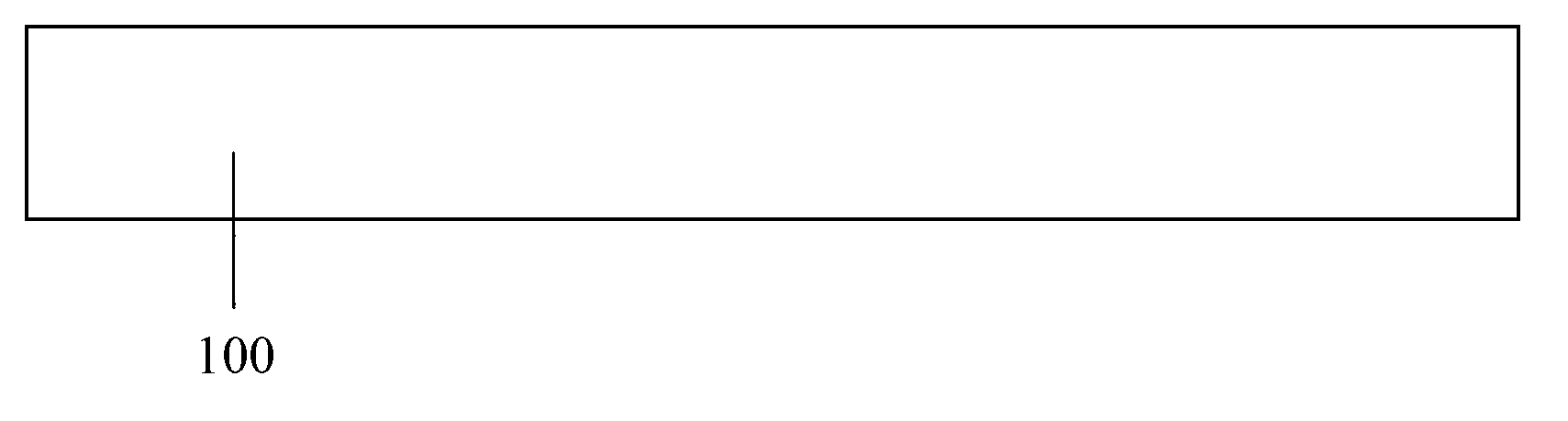

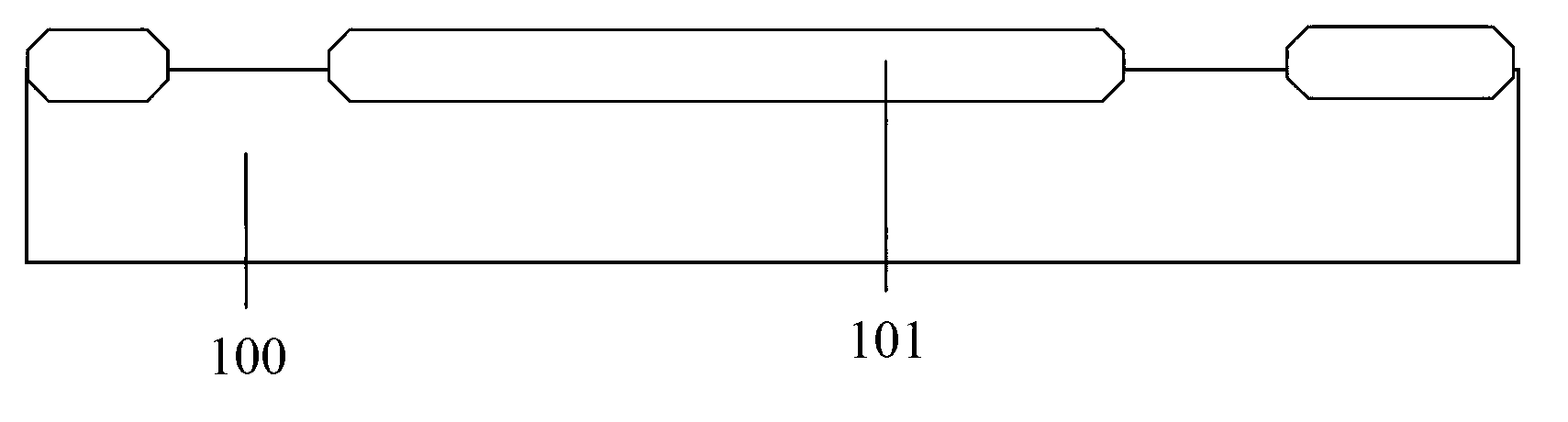

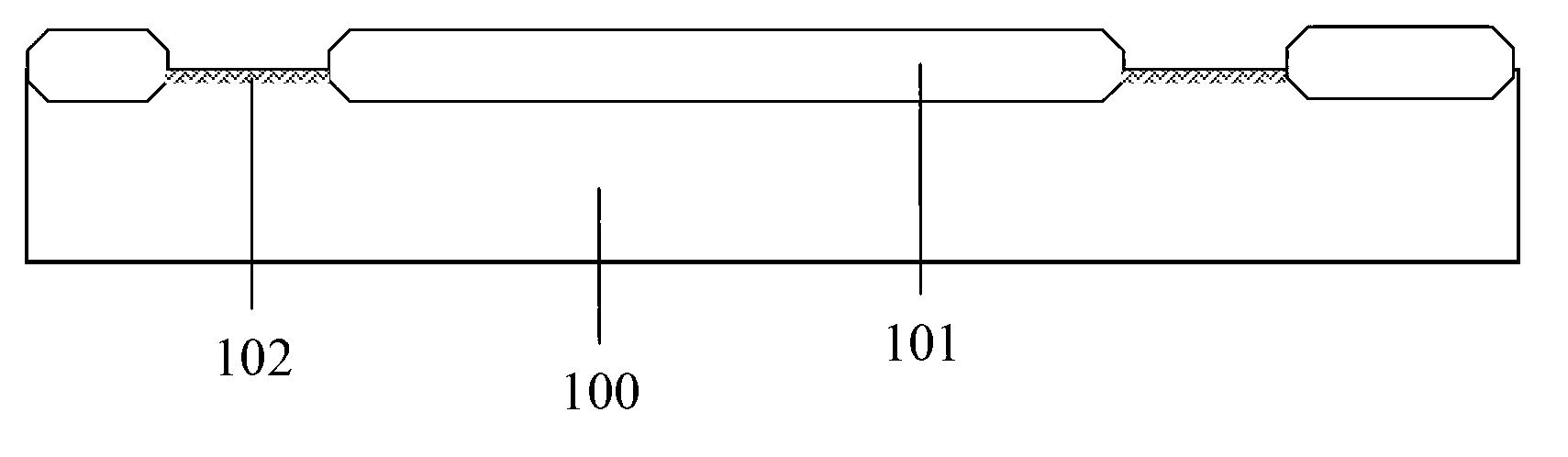

[0042] The preparation process of a Schottky diode of the present invention includes two parts of the process, as shown in Figures A1-A5: including a silicon substrate 100, a field silicon dioxide 101, a titanium silicide 102, a first dielectric 103, and a second dielectric 104 , Tungsten plug 105.

[0043] Figures A1 to A5 described in the present invention are the process of making the substrate by the existing standard submicron or deep submicron CMOS / BiCMOS process: the function of the substrate is to provide the negative pole and contact of the Schottky diode, the substrate 100 is the negative pole, and the negative pole contacts It is composed of titanium silicide 102 and tungsten plug 105 .

[0044] As shown in Figures B1 to B7: it includes a first photoresist 106, a metal titanium 107, a metal titanium nitride 108, a Schottky silicide 109, a metal cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com