Preparation method for controlled-release fertilizer special for mechanically applied rice

A technology of controlled-release fertilizers and controlled-release fertilizers, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems that the outer film of fertilizers is easily broken, unsuitable for mechanical fertilization, and poor particle uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

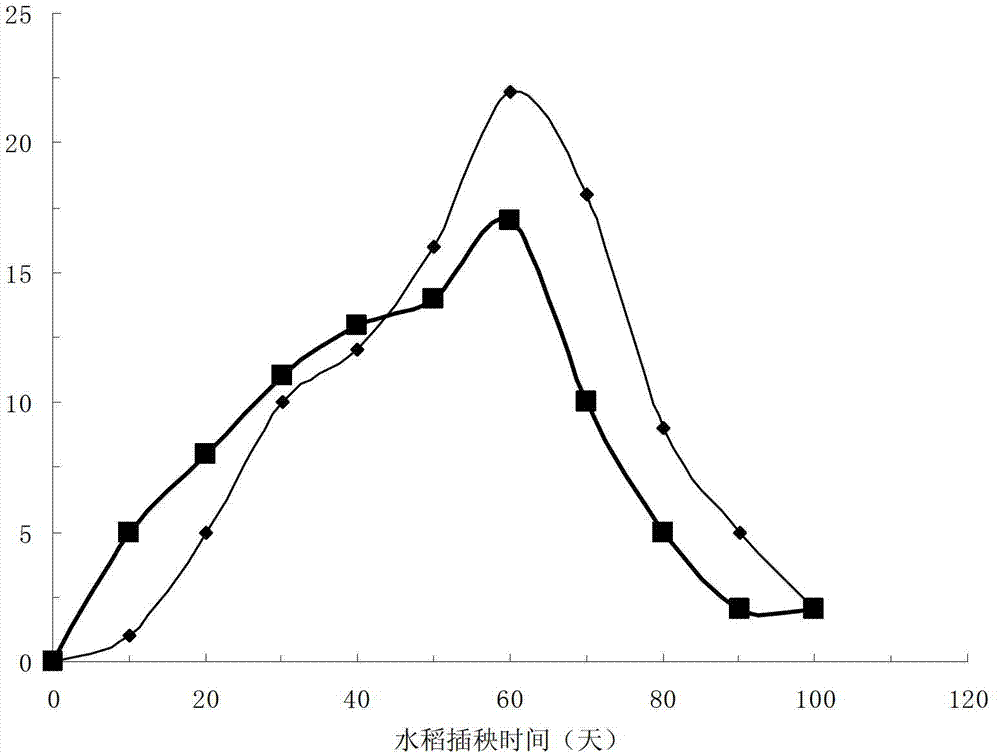

Image

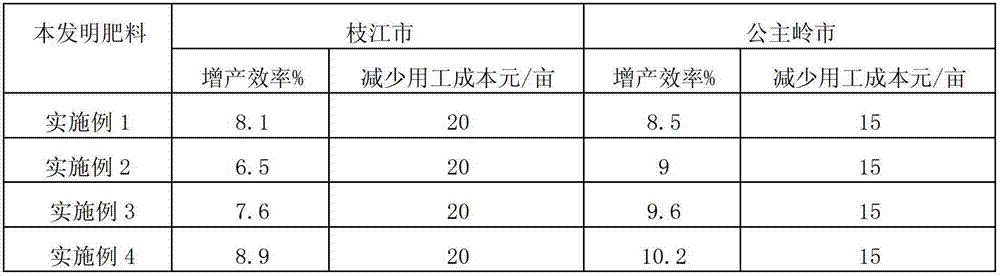

Examples

Embodiment Construction

[0011] A method for preparing a special controlled-release fertilizer for machine-applied rice. The high-tower granulated compound fertilizer is used as the core fertilizer for double-layer coating. The steps are as follows:

[0012] (1) Preparation of core fertilizer

[0013] Urea, monoammonium phosphate, and potassium chloride are mixed according to a mass ratio of 1: (0.25~0.4): (0.20~0.6), and compound fertilizer is obtained by high-tower granulation according to the prior art, sieved, and a particle size of 2-4 is selected. mm of granular fertilizer as a core fertilizer;

[0014] (2) Preparation of bottom urea-coated fertilizer

[0015] Preheat the core fertilizer in step (1) to 40°C to 50°C in the drum, and spray the molten urea solution at 125°C on the continuously rotating core fertilizer particles in the drum to form a urea film. The quality accounts for 4~6wt% of the core fertilizer quality, and the urea-coated fertilizer is obtained;

[0016] (3) Preparation of o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com