Non-solvent type high-temperature resistant strippable protection ink, and preparation method thereof

A technology for protecting ink and high temperature resistance, applied in ink, household appliances, applications, etc., can solve the problems of cumbersome preparation process of peelable ink, large demand for peelable ink, and inability to recycle and reuse, so as to save the reaction process, Eliminate pollution and simplify the effect of demanding requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

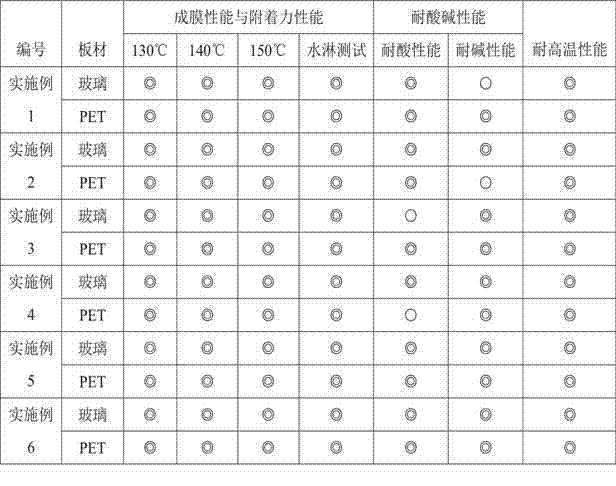

Examples

Embodiment 1

[0031] A non-solvent type high temperature resistant peelable protective ink, which is prepared from the following raw materials in weight ratio: 65g of vinyl acetate resin, 35g of plasticizer trioctyl trimellitate, 0.2g of epoxy resin, heat stable Dibutyltin dilaurate 0.5g, fumed silica 1g, phthalocyanine blue toner 0.3g, leveling agent 0.6g, silicone defoamer 0.6g and silicone surfactant (German BYK Chemicals, Model BYK-333) 1g.

[0032] In this example, the degree of polymerization of the vinyl chloride resin is 600, the mass content of the vinyl vinyl resin is 12%, analytically pure, from Shanghai Arkema Gaoyuan Chemical Co., Ltd.; the epoxy value of the epoxy resin is 0.38, from Baling Petrochemical Chemical Company; the type of leveling agent It is Modaflow Resin2100; the model of silicone defoamer is X933, Germany Keying Chemical; the model of silicone surfactant is BYK-333, Germany BYK Chemicals.

[0033] A preparation method of a non-solvent type high temperature res...

Embodiment 2

[0039] A non-solvent type high temperature resistant peelable protective ink, which is prepared from the following raw materials in weight ratio: 60g of vinyl acetate resin, 40g of plasticizer trioctyl trimellitate, 0.2g of epoxy resin, heat stable Agent dibutyltin dilaurate 0.8g, fumed silica 1.4g, phthalocyanine blue toner 0.5g, leveling agent 0.8g, silicone defoamer 0.6g and silicone surfactant 0.8g.

[0040]In this example, the degree of polymerization of the vinyl chloride resin is 600, and the content of the vinyl vinyl resin is 12%; the epoxy value of the epoxy resin is 0.38, from Baling Petrochemical Chemical Company; the model of the leveling agent is Modaflow Resin 2100; the model of the silicone defoamer is X933 , Keying Chemicals, Germany; silicone surfactant type BYK-333, BYK Chemicals, Germany.

[0041] A preparation method of a non-solvent type high temperature resistant peelable protective ink, which comprises the following steps:

[0042] 1) Prepare raw mater...

Embodiment 3

[0047] A non-solvent type high temperature resistant peelable protective ink, which is prepared from the following raw materials in weight ratio: 55g of vinyl acetate resin, 45g of plasticizer trioctyl trimellitate, 0.2g of epoxy resin, heat stable Agent dibutyl tin dilaurate 1g, fumed silica 1.8g, phthalocyanine blue toner 0.5g, leveling agent 1g, silicone defoamer 0.8g and silicone surfactant 1g.

[0048] In this example, the degree of polymerization of the vinyl chloride resin is 600, and the content of the vinyl vinyl resin is 12%; the epoxy value of the epoxy resin is 0.38, from Baling Petrochemical Chemical Company; the model of the leveling agent is Modaflow Resin 2100; the model of the silicone defoamer is X933 , Keying Chemicals, Germany; silicone surfactant type BYK-333, BYK Chemicals, Germany.

[0049] A preparation method of a non-solvent type high temperature resistant peelable protective ink, which comprises the following steps:

[0050] 1) Prepare raw materials...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com