Carbon source combination for increasing microbial oil yield

A technology of microorganisms and microbial fermentation, applied in the direction of microorganism-based methods, microorganisms, biochemical equipment and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] High erucic acid rapeseed oil, as the carbon source of the fermentation medium, can be converted into erucic acid-free and LCPUFA-rich oil products through the fermentation of Schizochytrium spATCC20888.

[0074] The cultivation steps are as follows:

[0075] (1) Streak inoculation of the glycerol tube bacteria stored in the ultra-low temperature refrigerator to the slant for activation. The activation medium is: glucose 5g / L, peptone 1g / L, yeast powder 1g / L, agar powder 18g / L, sea salt 30g / L. Incubate at 28°C for 40 hours.

[0076] (2) Pick the activated single colony and inoculate it into the seed liquid culture medium (recipe is shown in Table 1), in a liquid volume of 50ml / 250ml Erlenmeyer flask, and culture on a shaker at 28°C and 200rpm for 48 hours. The concentration of seed liquid is about 15-20g / L dry weight.

[0077] Table 1 Seed medium formula (g / L)

[0078] project

content

project

content

project

content

glucose

...

Embodiment 2

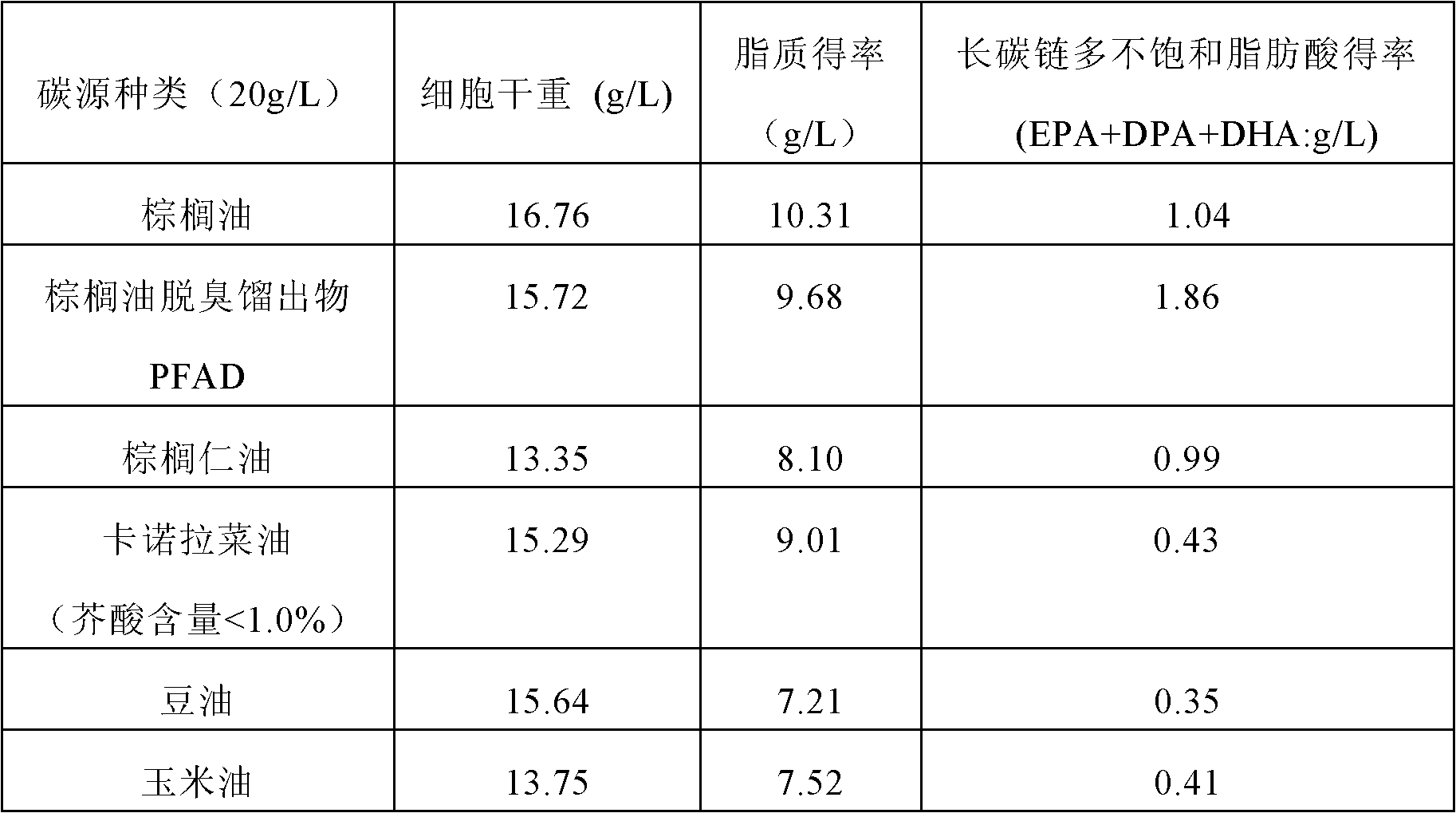

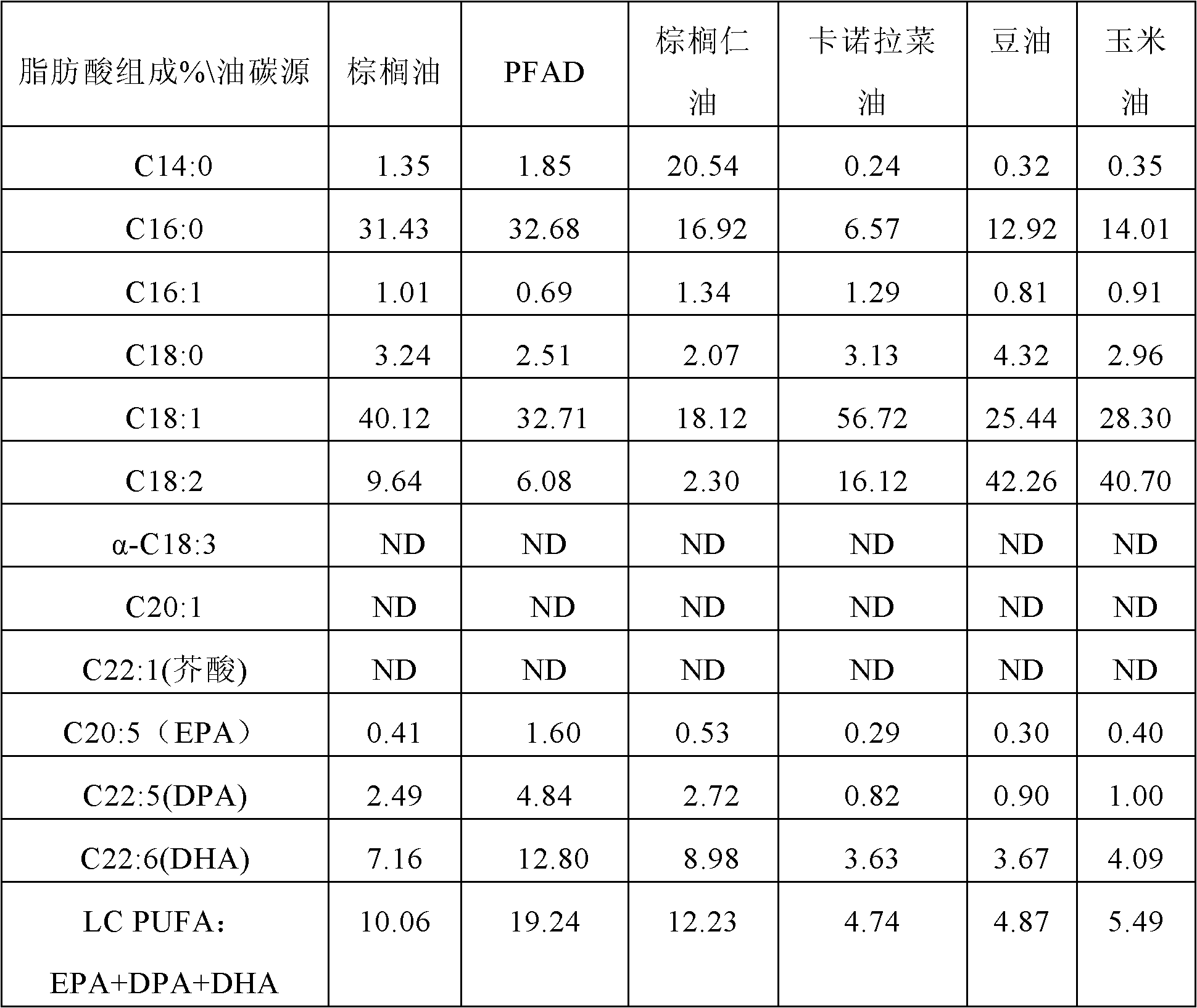

[0088] Using oil or oil refining by-products as a carbon source for fermentation, through the fermentation of Schizochytrium sp., it was found that the palm oil deodorized distillate PFAD was very efficient as a carbon source, and the fermented oil had very good nutritional value.

[0089] The cultivation steps are the same as the parts (1), (2), (3) and (4) of the embodiment.

[0090] Oil carbon sources were selected respectively: palm oil (Malaysia Pasir Gudang Edible Oil Company), palm oil deodorized distillate PFAD (Malaysia Pasir Gudang Edible Oil Company), palm kernel oil (Malaysia Pasir Gudang Edible Oil Company), Kano Pull (canola) vegetable oil (Shanghai Kerry Food Co., Ltd.), soybean oil (Shanghai Kerry Food Co., Ltd.), corn oil (Shanghai Kerry Food Co., Ltd.).

[0091] Palm oil deodorization distillate PFAD contains about 47.2% by weight palmitic acid (16:0), about 4.5% by weight stearic acid (18:0), about 36.7% oleic acid (18:1), about 9.7% by weight % of linoleic...

Embodiment 3

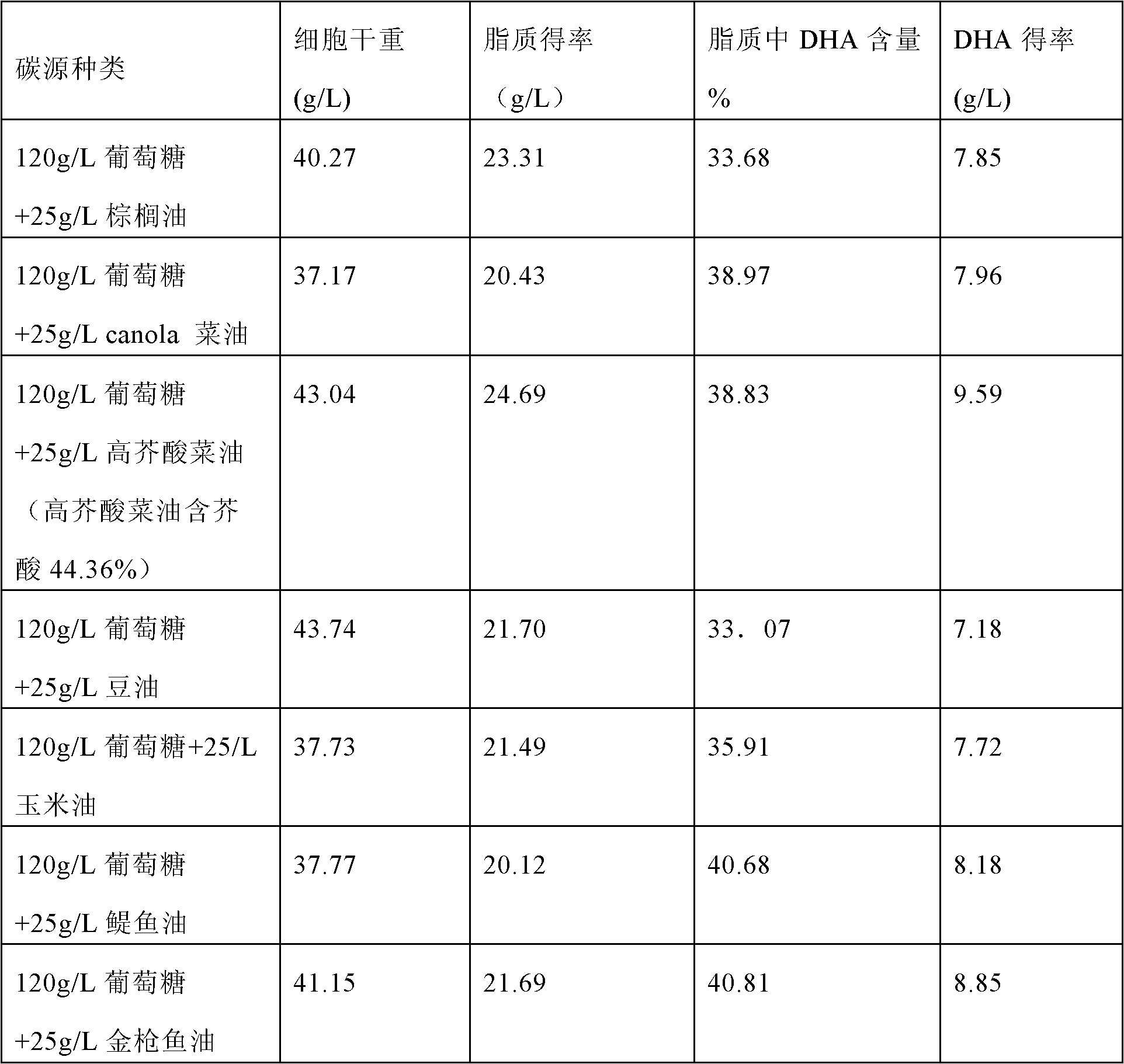

[0099] Comparing various types of oil and glucose to form a composite carbon source, comparing the biomass density, lipid yield, and lipid DHA yield of Schizochytrium algae.

[0100] Cultivate steps with (1), (2), (3), (4) of embodiment 1

[0101] Table 5 Biomass, lipid yield, DHA content in lipid, and DHA yield obtained from different composite carbon sources

[0102]

[0103] From the data in Table 5, it can be seen that when high erucic acid rapeseed oil (Sichuan Kerry Food Co., Ltd.), anchovy oil (Tecnológica de Alimentos S.A. company in Peru) and tuna oil (LYSI COMPANY in Iceland) containing fatty acid carbon number greater than 18 were combined with glucose Cultivate Schizochytrium algae to produce algae oil. Compared with soybean oil, canola oil, corn oil, and palm oil (the source is the same as in Example 2) with fatty acid carbon number equal to 18 or less than 18, the DHA yield of the obtained algae oil is significantly improved. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com