Silicon wafer drying furnace capable of preventing metal ion pollution and silicon wafer drying method

A metal ion and drying furnace technology, applied in drying, dryers, furnaces, etc., can solve the problems of easy aging of resin mesh belts, secondary pollution of silicon wafers, high energy consumption of drying furnaces, etc., to avoid secondary Pollution, production efficiency improvement, and the effect of saving furnace space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

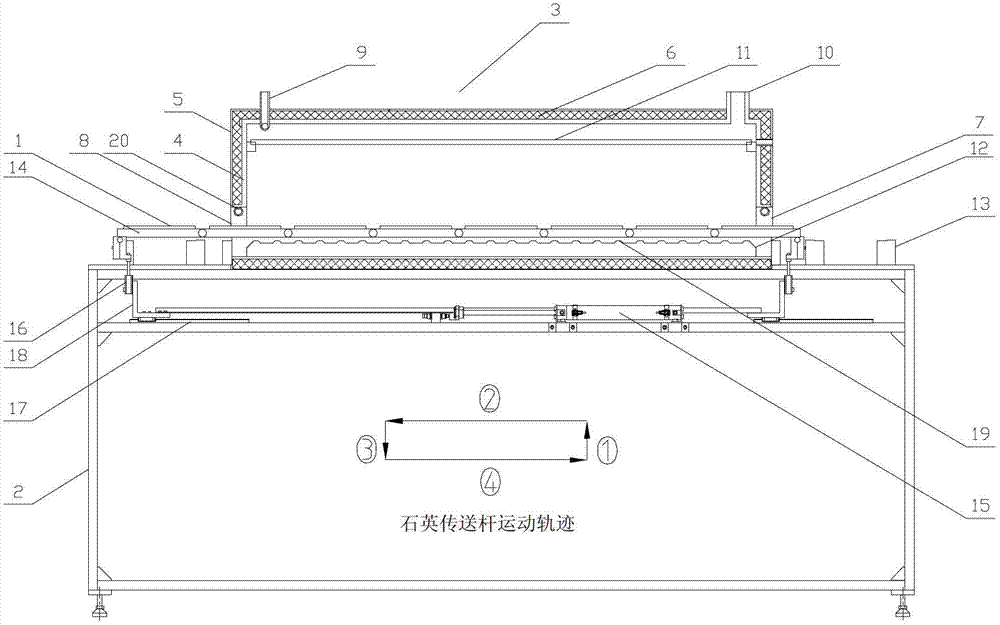

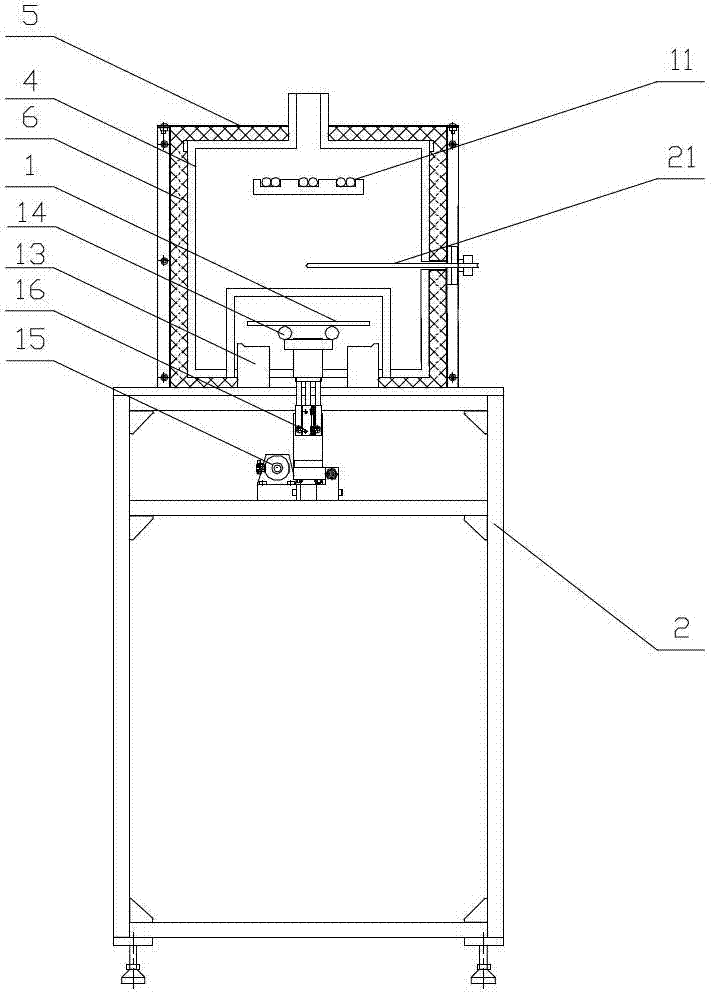

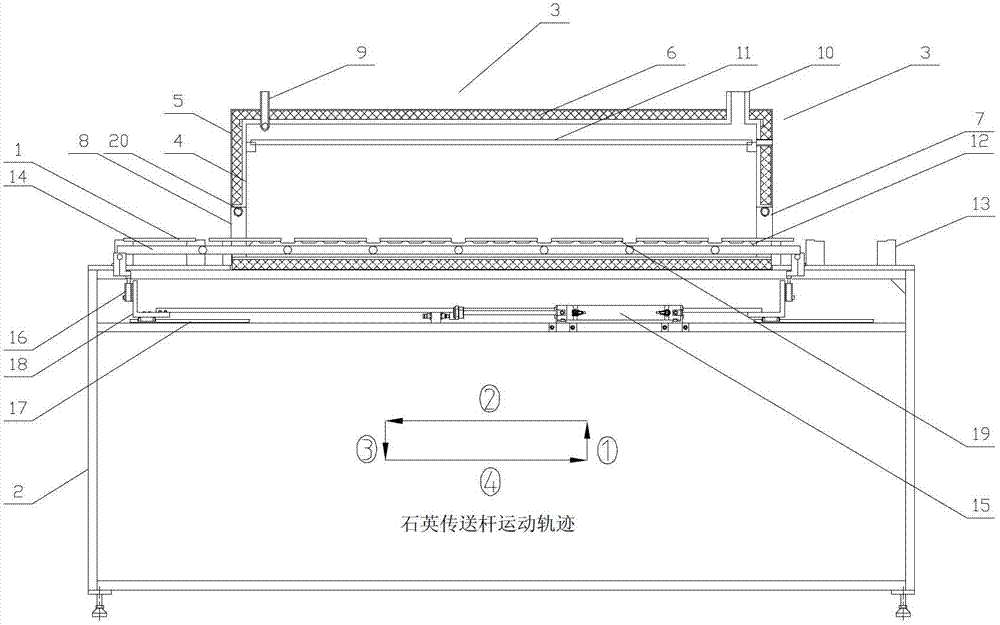

[0047] Embodiment: a kind of metal ion pollution-proof silicon wafer drying furnace of the present embodiment is used for drying operation of solar cell silicon wafer 1, such as figure 1 and figure 2 As shown, the drying furnace is placed on the frame 2, including a furnace body 3, a heating device installed in the furnace body, a silicon wafer conveying device and a control unit, wherein:

[0048] The furnace body includes an inner wall plate 4 and an outer furnace plate 5, the inner wall plate is a quartz plate, the outer furnace plate is a PVDF resin plate, and the cavity between the inner wall plate and the outer furnace plate is filled with a heat insulating layer 6, and the heat insulating layer is high Pure quartz fiber heat insulation cotton is designed with silicon wafer inlet 7 and silicon wafer outlet 8 on both sides of the furnace body, and an opening corresponding to the silicon wafer conveying mechanism is provided at the bottom of the furnace body. Quartz tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com