Preparation method of fungicide for anaerobic degradation of hydrochloric ether and application thereof

A technology of chlorinated hydrocarbons and degrading bacteria, applied in the field of biological treatment of groundwater pollution, can solve the problems of lack of microorganisms that degrade chlorinated hydrocarbons, restrict the development and application of chlorinated hydrocarbon-contaminated soil and groundwater anaerobic bioremediation technology, and achieve The effect of simple system design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, the preparation method of chlorinated hydrocarbon anaerobic degradation bacterial agent

[0030] To prepare the anaerobic degradation bacterial agent for hydrocarbons, the specific steps are as follows:

[0031] (1) Configuration of anaerobic medium, configure inorganic salt medium and add it to a 1 L Erlenmeyer flask, add 1 L of deionized water, wrap it with gauze and kraft paper, and put it in a high-pressure steam sterilizer at 121 oC high-pressure steam Sterilize for 20 minutes, take out the culture medium, and heat it until boiling, add resazurin indicator with a sterilized dropper until the solution turns blue;

[0032] (2) After the culture medium is cooled, replace the gauze and kraft paper with a sterilized rubber stopper matching the nitrogen filling device under aseptic conditions, open the high-purity nitrogen valve, and let the high-purity nitrogen pass through the closed heated copper Silk, further remove a small amount of oxygen inside, p...

Embodiment 2

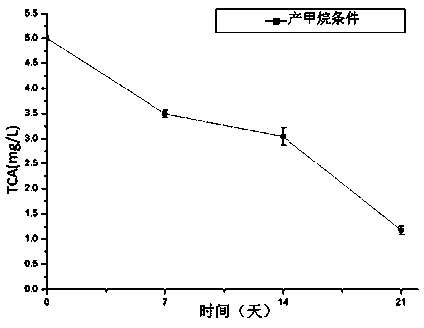

[0041] TCA degradation characteristics under embodiment 2, producing methane condition

[0042] Utilize the flora domesticated by the method of the present invention to carry out TCA anaerobic degradation test, the methanogenic anaerobic degradation system is measured once every 7 days, 21 days is a cycle, draw the degradation curve under the methanogenic condition according to the measurement result as follows figure 1 Show. TCA degraded rapidly from 5 mg / L to 3.5 mg / L at 0-7 d, and the removal rate of TCA was 0.0429 mg / Ld, which was 30% removed; the degradation rate decreased at 7-14 d, and the concentration of TCA decreased from 3.5 mg / L decreased to 3.04 mg / L, the removal rate of TCA was 0.0 188 mg / Ld, and the removal rate was 9.2%; the degradation rate was the largest at 14-21 d, and the concentration of TCA decreased from 3.04 mg / L to 1.17 mg / L, and the removal rate of TCA The rate was 0.08788 mg / Ld, and 37.4% was removed; during the 21-day degradation process, the t...

Embodiment 3

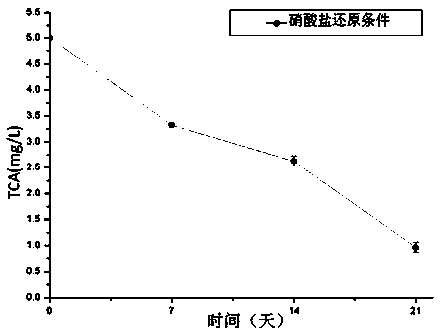

[0043] TCA degradation characteristics under embodiment 3, nitrate reduction condition

[0044] Utilize the flora domesticated by the method of the present invention to carry out TCA anaerobic degradation test, the nitrate reduction anaerobic degradation system is measured once every 7 days, 21 days is a cycle, draw the degradation curve under the nitrate reduction condition according to the measurement result as follows figure 2 The results showed that TCA degraded rapidly from 5 mg / L to 3.32 mg / L at 0-7 d and 14-21 d, and the removal rate of TCA was 0.048 mg / Ld, which removed 33.6% and decreased from 2.626 mg / L decreased to 0.961 mg / L, the removal rate of TCA was 0.0405 mg / Ld, and the removal rate was 33.3%; the degradation rate slowed down after 7-14 days, and the concentration of TCA decreased from 3.32 mg / L to 2.626 mg / L, and the removal rate of TCA was 0.02986 mg / Ld, removal of 13.9%; in the 21-day degradation process, the total removal rate of TCA reached 80.8%, comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com