Anti-etching compound and base material coated with same

A composition and anti-etching technology, applied in photosensitive materials for opto-mechanical equipment, photo-engraving process of pattern surface, instruments, etc., can solve the problem that potassium permanganate cannot meet the needs, the anti-etching composition cannot resist etc. problem, to achieve the effect of excellent anti-oxidation and excellent linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

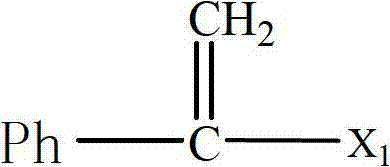

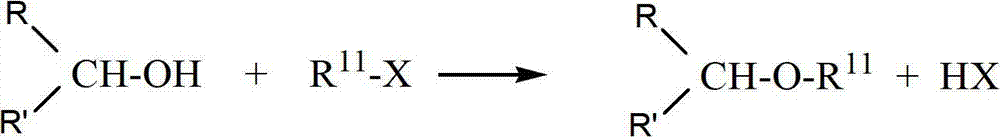

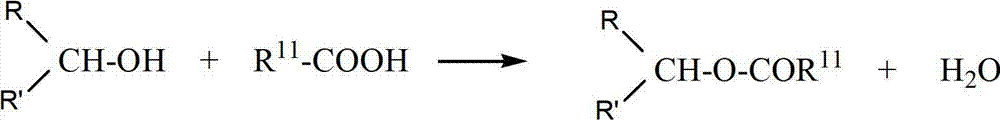

Method used

Image

Examples

Synthetic example 1

[0095]Add 200g of novolac epoxy resin CNE-202 (Taiwan Changchun Life Resin Factory, epoxy equivalent 210), 250g of propylene glycol methyl ether acetate (PMA) and 69g of acrylic acid into a 1L reactor, heat and melt, and then add p-benzene 0.5g of diphenol and 1.5g of triphenylphosphine were reacted at 108°C for 12 hours to obtain a product with an acid value (determined according to the measurement standard for the acid value of unsaturated polyester resin in GB2895-1982, the same below) as 3, and then four 85g of hydrophthalic anhydride, heated to 100°C, reacted for 6 hours, the acid value was measured as 52 by sampling, and the hydroxyl content was calculated to be 0.392mol by acid value, adding triphenylmethyl ether and 0.5 g of 4-dimethylaminopyridine (DMAP) catalyst, reacted for 4 hours to obtain resin solution A1.

Synthetic example 2

[0097] Add 200g of novolac epoxy resin CNE-202 (Taiwan Changchun Life Resin Factory, epoxy equivalent 210), 250g of PMA and 69g of acrylic acid into a 1L reactor, heat and melt, then add 0.5g of hydroquinone and triphenylphosphine 1.5g, reacted at 108°C for 12 hours to obtain a product with an acid value of 3, then added 80g of tetrahydrophthalic anhydride, heated to 100°C, and reacted for 6 hours. The acid value was measured as 49 by sampling and calculated by acid value To obtain a hydroxyl content of 0.425 mol, add triphenylmethyl ether and 0.5 g of DMAP catalyst in an equimolar amount to the hydroxyl group, and react for 4 hours to obtain resin solution A2.

Synthetic example 3

[0099] Add 200g of linear o-cresol formaldehyde resin (Dainippon Ink Co., Ltd. epoxy resin N-680), 200g of ethylene glycol butyl ether acetate, 72g of acrylate and 0.5g of catechol into a 1L reactor, and heat up to React at 120°C for 24 hours until the acid value is 1, add 60g of tetrahydrophthalic anhydride, react at 105°C for 6 hours, the acid value is 36 by sampling, and the hydroxyl content is 0.557mol based on the acid value calculation. The molar amount of methoxychloromethane and 0.5 g of triethylamine catalyst were reacted for 4 hours to obtain resin solution A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com