Method for preparing fermented fodder with shrimp heads

A fermented feed and shrimp head technology, applied in animal feed, animal feed, applications, etc., can solve the problems of small peptide content, low organic acid content, short storage time of finished feed, increase of production cost of finished products, etc., to achieve extended Save time, ensure good quality, and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

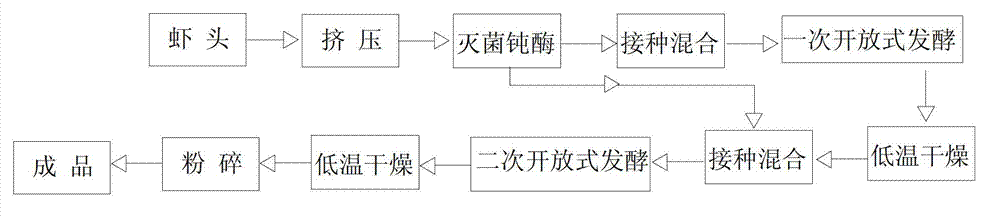

[0025] Craft such as figure 1 As shown, 1 ton of fresh shrimp heads are squeezed and separated to obtain shrimp shells and semi-liquid shrimp paste. The shrimp paste is 496-633 kg, and the shrimp shells are directly dried to make chitin and other raw materials; the obtained shrimp Heat the slurry to 92°C and keep it for 15 minutes to complete the sterilization and passivation of the shrimp slurry, which can ensure that the shrimp slurry does not deteriorate within a certain period of time, and basically removes the activity of some enzymes contained in the shrimp slurry itself, ensuring the cost of feed. Stability: add 500kg of sterilized and passivated shrimp paste to 500kg of soybean meal, add 1.2kg of solid compound fermentation bacteria to inoculate and mix (10%-40% for lactic acid bacteria, 10%-40% for yeast, 10% for bacillus %-40%, Aspergillus niger is 5%-10%, the strain content is 2×10 11 -8×10 11 cfu / g), and add 3kg of starch, 3kg of molasses, and 1.2kg of peptone an...

Embodiment 2

[0029] Craft such as figure 1 As shown, 1 ton of fresh shrimp head is squeezed and separated to obtain shrimp shells and semi-liquid shrimp paste. The shrimp paste is 496-633 kg. The extruded shrimp shells are directly dried to make chitin and other raw materials; Heat the obtained shrimp paste to 93°C and maintain it for 20 minutes to complete the sterilized inactivation of the shrimp paste; add 600kg of the sterilized inactivated shrimp paste to 500kg of soybean meal, and add solid composite fermentation bacteria to inoculate and mix 1.8kg (of which lactic acid bacteria 10%-40%, 10%-40% for yeast, 10%-40% for Bacillus, 5%-10% for Aspergillus niger, the strain content is 4×10 11 -9×10 11 cfu / g), and add 4kg of starch, 4kg of molasses, and 1.8kg of peptone and mix thoroughly (after mixing, the water content of the material is 49.8%), put the mixed material into an open fermentation frame and place it in an open environment Carry out fermentation (the fermentation temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com