Method for producing ammonium chloride with low potassium and sodium

A technology of ammonium chloride and potassium sodium, applied in the direction of ammonium halide, etc., can solve the problems of being unsuitable for large-scale industrial production, high price of crown ether, and uneconomical, etc., and achieves a significant effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

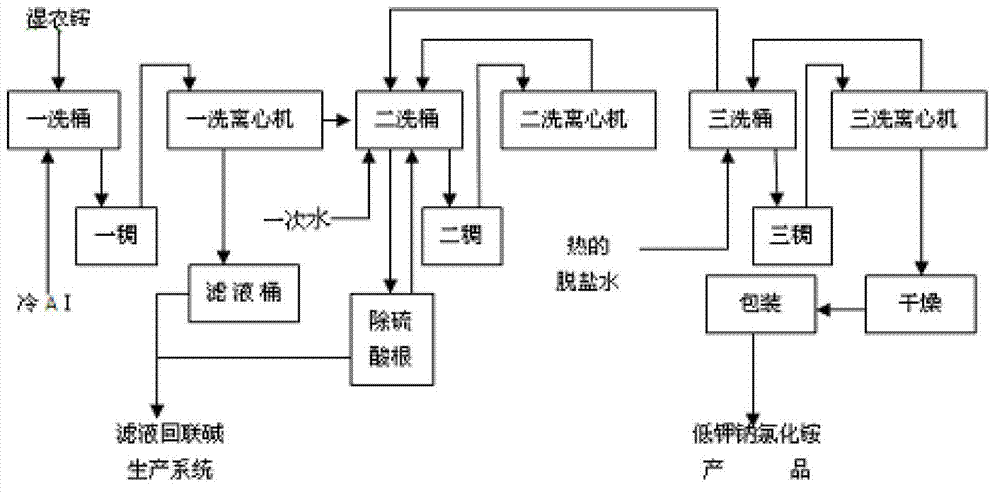

[0024] As shown in the figure: In a washing bucket, the cold ammonia mother liquor I (cold AI) sent by the combined alkali production system and the agricultural ammonium chloride are fully stirred and washed, and the solid / liquid volume ratio of the mixed solution during washing is 15%. , and then sent to the first washing thickener for thickening; and after the solid-liquid separation of the first washing centrifuge, the first-grade solid ammonium chloride is obtained and enters the second washing bucket, and the overflow liquid of the first washing thickener and the filtrate of the first washing separator are passed through the filtrate After the barrels are collected, they return to the combined alkali production system; after the first stage of centrifugal separation, the main content of ammonium chloride can reach 99.0~99.2%.

[0025] In the secondary washing bucket, the primary solid ammonium chloride and circulating mother liquor I are fully stirred and washed, and the ...

Embodiment 2

[0028] As shown in the figure: In a washing bucket, the cold ammonia mother liquor I (cold AI) sent by the combined alkali production system and the agricultural ammonium chloride are fully stirred and washed, and the solid / liquid volume ratio of the mixed solution during washing is 25%. , and then sent to the first washing thickener for thickening; and after the solid-liquid separation of the first washing centrifuge, the first-grade solid ammonium chloride is obtained and enters the second washing bucket, and the overflow liquid of the first washing thickener and the filtrate of the first washing separator are passed through the filtrate After the barrels are collected, they return to the combined alkali production system; after the first stage of centrifugal separation, the main content of ammonium chloride can reach 99.0~99.2%.

[0029] In the secondary washing bucket, the first-grade solid ammonium chloride and the circulating mother liquor I are fully stirred and washed, ...

Embodiment 3

[0032] As shown in the figure: in a washing bucket, the cold ammonia mother liquor I (cold AI) sent by the combined alkali production system and the agricultural ammonium chloride are fully stirred and washed, and the solid / liquid volume ratio of the mixed solution during washing is 35%. , and then sent to the first washing thickener for thickening; and after the solid-liquid separation of the first washing centrifuge, the first-grade solid ammonium chloride is obtained and enters the second washing bucket, and the overflow liquid of the first washing thickener and the filtrate of the first washing separator are passed through the filtrate After the barrels are collected, they return to the combined alkali production system; after the first stage of centrifugal separation, the main content of ammonium chloride can reach 99.0~99.2%.

[0033]In the secondary washing bucket, the first-grade solid ammonium chloride and the circulating mother liquor I are fully stirred and washed. T...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap