Method for producing impurity-bearing calcium chloride solution by utilization of cold rolling acid-bearing wastewater

A technology of calcium chloride solution and pickling waste liquid, applied in the direction of calcium/strontium/barium chloride, process efficiency improvement, calcium/strontium/barium halide, etc., can solve the problems affecting the normal operation of the next process, pH value Exceeding the standard, ecological environment hazards and other problems, to achieve the effect of large promotion and application value, saving sewage treatment costs, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

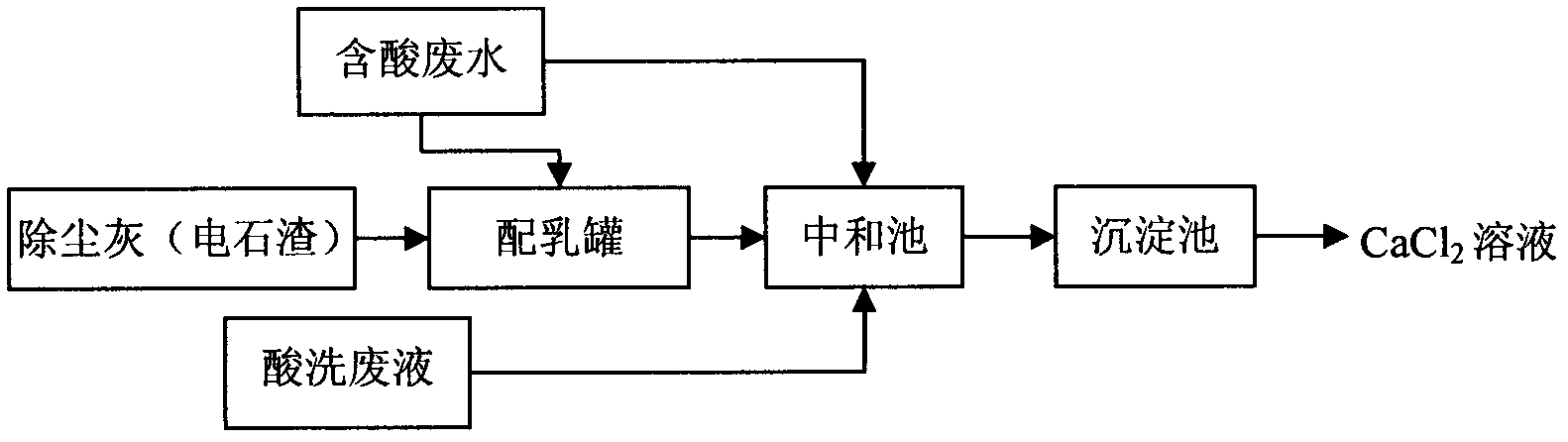

Embodiment 1

[0022] Check that the molar concentrations of cold-rolling acid-containing waste water and pickling waste liquid are 0.07mol / L and 2.53mol / L respectively, and check that the mass fraction of CaO in the LF furnace dust removal ash is 48%; determine the required preparation of CaCl-containing 2 The molar concentration of the wastewater solution is 0.18mol / L. The specific process is as follows: 1470kg and 15m 3 The cold-rolled acid-containing waste water was added to the milk mixing tank, and after stirring for 1 hour, lime milk was made; then the lime milk and 8.75m 3 The pickling waste liquid is added to the neutralization tank and injected into 46.25m 3 The cold-rolled acid-containing wastewater, the neutralized solution flows into the sedimentation tank for static precipitation, and the clear upper layer is CaCl 2 A liquid calcium chloride solution containing impurities with a molar concentration of 0.18mol / L.

Embodiment 2

[0024] Check that the molar concentrations of cold-rolling acid-containing waste water and pickling waste liquid are 0.06mol / L and 2.80mol / L respectively, and check that the mass fraction of CaO in calcium carbide slag is 60%; determine the required preparation of impurity-containing CaCl 2 The molar concentration of the solution is 0.18mol / L. The specific process is as follows: 1176kg of calcium carbide slag and 12m 3 The cold-rolled acid-containing waste water was added to the milk mixing tank, and after stirring for 1 hour, lime milk was made; then the lime milk and 7.66m 3 The pickling waste liquid is added to the neutralization tank and injected into the 50.34m 3 The cold-rolled acid-containing wastewater, the neutralized solution flows into the sedimentation tank for static precipitation, and the upper layer is clear as CaCl 2 A liquid calcium chloride solution containing impurities with a molar concentration of 0.18mol / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com