Ultra-wearproof epoxy precast slab and installation method thereof

An installation method and prefabricated panel technology, applied in the field of building materials, can solve the problems of easy falling off, high price, poor impact resistance, etc., and achieve the effect of ensuring the firmness of the installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

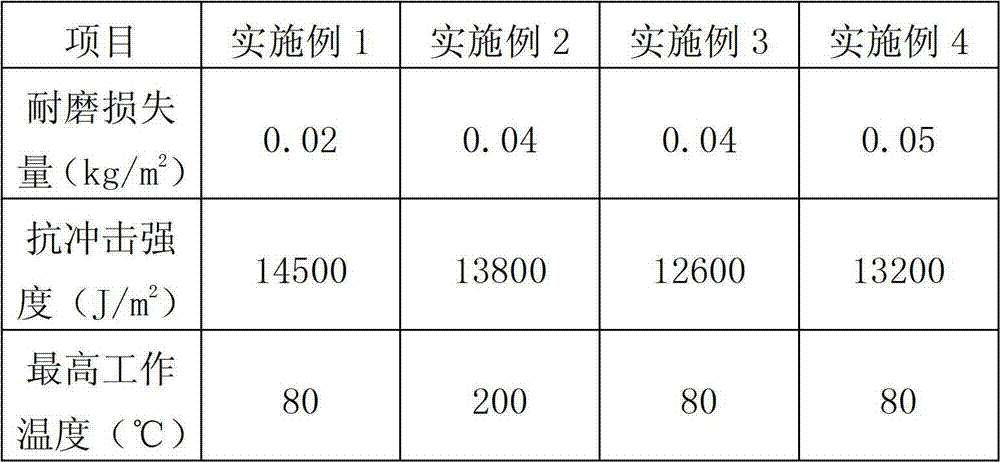

Embodiment 1

[0036] An epoxy-based wear-resistant prefabricated board, the raw material components of which are measured in parts by mass are as follows:

[0037] 30 parts of epoxy resin component, composed of 24 parts of E51 epoxy resin and 6 parts of reactive diluent AGE;

[0038] 12 parts of epoxy curing agent, composed of 3 parts of aromatic amine and 9 parts of amino-terminated polyether;

[0039] 200 parts of aggregate components, composed of 50 parts of fly ash, 50 parts of quartz sand and 100 parts of granite;

[0040] 5 parts of chopped fibers are indented steel fibers with a length of 30 mm and a diameter of 0.8 mm.

[0041] Stir the epoxy resin component, epoxy curing agent and aggregate component separately first, then mix the epoxy resin component and epoxy curing agent evenly, add the aggregate component and chopped fibers while stirring, Stirring was continued for another 3 minutes. Pour the stirred mixture into the mold, which can be self-flowing and densely formed witho...

Embodiment 2

[0043] 40 parts of epoxy resin components, all of which are E44 epoxy resin;

[0044] 15 parts of epoxy curing agent, all organic acid anhydrides, the molecular weight of the organic acid anhydride is between 180-200, and the molecular structure contains a benzene ring;

[0045] 180 parts of aggregate components, composed of 50 parts of fly ash, 50 parts of river sand and 80 parts of corundum;

[0046] 30 parts of chopped fiber, composed of 20 parts of indented steel fiber and 10 parts of glass fiber.

[0047] Mix the epoxy resin component and the epoxy curing agent evenly and heat to 150° C., add the aggregate component and chopped fibers while stirring, and continue stirring for 3 minutes. Pour the stirred mixture into the mold, vibrate and compact, and then solidify at 150°C for 8 hours before demoulding. A high temperature resistant (200°C) wear-resistant prefabricated board can be prepared, and because a large amount of chopped fiber is added , this kind of wear-resista...

Embodiment 3

[0049] 35 parts of epoxy resin components, consisting of 30 parts of E51 epoxy resin and 5 parts of reactive diluent BGE;

[0050] 10 parts of epoxy curing agent, which is an aliphatic amine with an amine value between 490-500;

[0051] 600 parts of aggregate components, composed of 150 parts of slag powder, 200 parts of river sand and 250 parts of limestone;

[0052] Chopped fiber component 0 parts.

[0053] The manufacturing method is the same as in Example 1, and because a large amount of aggregate components are added, the overall cost of this wear-resistant plate is lower compared with other examples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com