Method for directionally preparing theophylline-saccharin eutectic through membrane technology

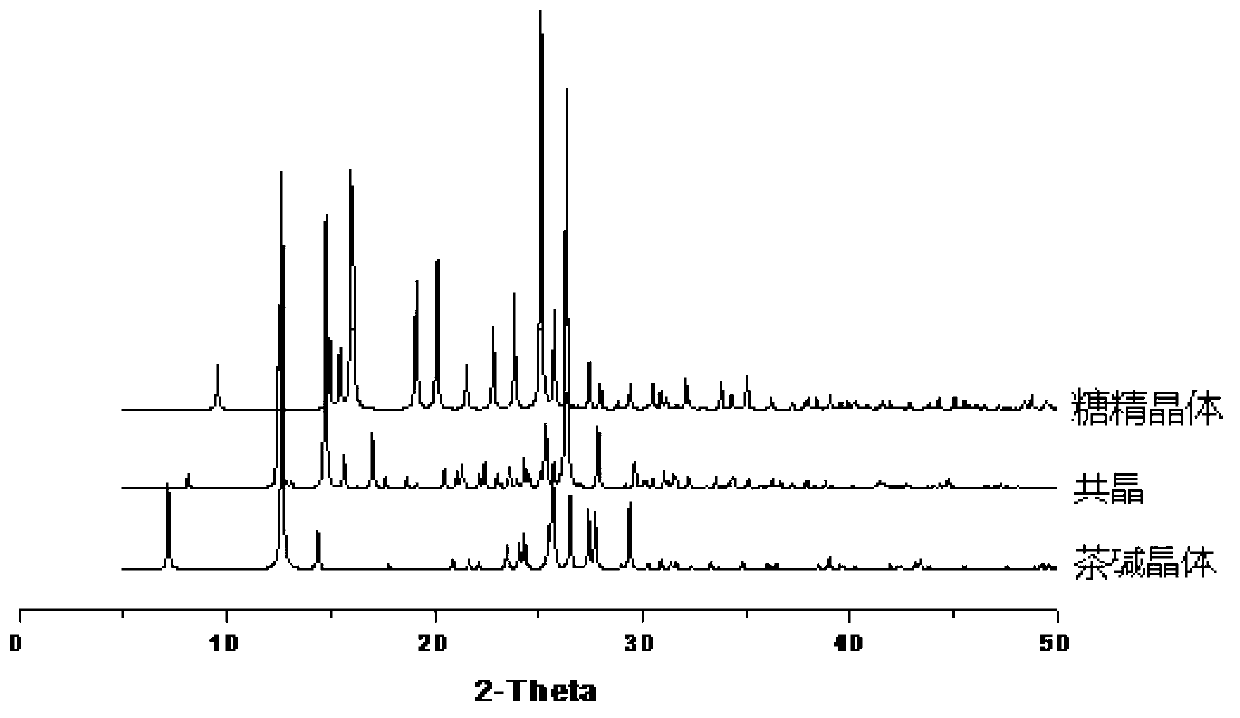

A membrane technology, theophylline technology, applied in the field of preparation of theophylline-saccharin co-crystal, can solve the problem of not being able to obtain pure co-crystal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Add 50ml of fresh Piranha solution into a large beaker, put the cut glass piece (20X20mm) into it, heat at a constant temperature of 70°C for 120 minutes, take out the glass piece, and wash with deionized water, isopropyl Wash carefully with alcohol, absolute ethanol and n-hexane, and dry to obtain hydroxylated glass flakes. Put the hydroxylated glass flakes into 60mL of 10mM aqueous solution containing 3-chloropropyltrimethoxysilane at room temperature, airtight Place it under the same conditions for 100 minutes to obtain a silanized glass sheet; wash the silanized glass sheet with fresh n-hexane, put it in anhydrous methanol for 10 minutes; wash it with anhydrous methanol, and dry it at 50°C 12h, a silane monomolecular self-assembled film was obtained on the surface of the glass sheet;

[0018] (2) Add 3.0g of theophylline and saccharin with a molar ratio of 1:1 into a container containing 100mL of methanol, heat to 50°C to dissolve all the solids; cool to 25°C, p...

Embodiment 2

[0021] (1) Add 50ml of fresh Piranha solution into a large beaker, put the cut glass piece (20X20mm) into it, heat at a constant temperature of 90°C for 90 minutes, take out the glass piece, and wash with deionized water, isopropyl Wash carefully with alcohol, absolute ethanol and n-hexane, and dry to obtain hydroxylated glass flakes. Put the hydroxylated glass flakes into 60mL of 15mM aqueous solution containing 3-aminopropyltrimethoxysilane at room temperature, airtight Place it under the same conditions for 150 minutes to obtain a silanized glass sheet; wash the silanized glass sheet with fresh n-hexane, put it in anhydrous methanol for 5 minutes; wash it with anhydrous methanol, and dry it at 80°C 8h, a silane monomolecular self-assembled film was obtained on the surface of the glass sheet;

[0022] (2) Add 4.0g of theophylline and saccharin with a molar ratio of 1:3 into a container containing 100mL of ethanol, heat to 50°C to dissolve all the solids; cool to 30°C, put T...

Embodiment 3

[0025] (1) Add 50ml of fresh Piranha solution into a large beaker, put the cut glass piece (20X20mm) into it, heat at a constant temperature of 80°C for 100 minutes, take out the glass piece, and wash with deionized water, isopropyl Wash carefully with alcohol, absolute ethanol and n-hexane, and dry to obtain hydroxylated glass flakes. Put the hydroxylated glass flakes into 60mL aqueous solution containing n-propyltrimethoxysilane with a concentration of 20mM at room temperature and under airtight conditions. Place it for 150 minutes to obtain a silanized glass sheet; wash the silanized glass sheet with fresh n-hexane, put it into anhydrous methanol for 20 minutes; wash it with anhydrous methanol, and dry it at 70°C for 10 hours. A silane monomolecular self-assembled film was obtained on the surface of the glass sheet;

[0026] (2) Add 5.0g of theophylline and saccharin with a molar ratio of 1:5 into a container containing 100mL of ethanol, heat to 50°C to dissolve all the sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com