Preparation method of gel nano particles in thermosensitivie nuclear shell structure and application of product thereof

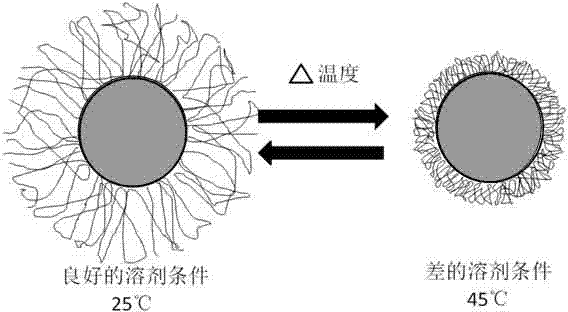

A technology of core-shell structure and nanoparticles, which is applied in the preparation of temperature-sensitive core-shell structure gel nanoparticles and the application of products, which can solve the problems of catalytic rate decline and achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

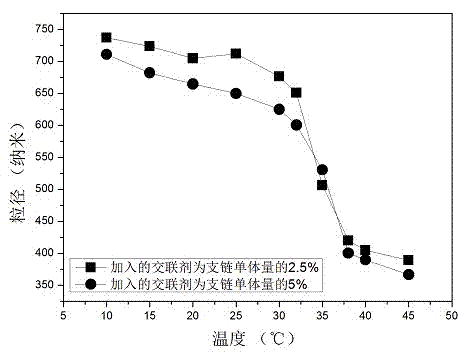

Embodiment 1

[0024] Add 35 ml of polybutadiene core (11.5% solid content) and 165 ml of water into a three-necked flask, use mechanical stirring (300 rpm) to fully dissolve, vacuumize and fill with nitrogen for 3 times, Under protection, the temperature was raised to 70°C, and after stabilization, 0.5 grams of potassium persulfate, a thermal initiator dissolved in water, was added. After reacting for 30 minutes, 2.0 grams of N-isopropylacrylamide monomer dissolved in water and N, N'- 0.07 g of methylenebisacrylamide crosslinking agent. After reacting for 1.5 hours, the microgel emulsion was obtained, and the particle diameter of the temperature-sensitive core-shell gel nanoparticles was measured at 25° C. by a dynamic light scattering instrument to be 712 nanometers.

Embodiment 2

[0026] Add 35 ml of polybutadiene core (11.5% solid content) and 165 ml of water into a three-necked flask, use mechanical stirring (350 rpm) to fully dissolve, vacuumize and fill with nitrogen for 3 times. Under protection, the temperature was raised to 80°C, and after stabilization, 0.3 grams of potassium persulfate, a thermal initiator dissolved in water, was added. After 20 minutes of reaction, 1.25 grams of N-isopropylacrylamide monomer dissolved in water and N, N'- 0.08 g of methylenebisacrylamide crosslinking agent. After reacting for 2 hours, a microgel emulsion was obtained, and the particle size of the temperature-sensitive core-shell gel nanoparticles was measured at 25° C. by a dynamic light scattering instrument to be 650 nm.

Embodiment 3

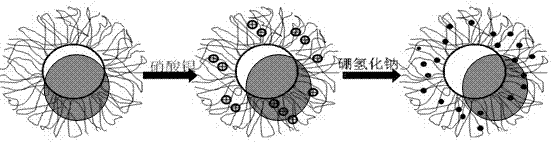

[0028] The solid content of Example 1 or Example 2 is that 120 milliliters of 2% nano-microgel emulsion is placed in a 500 milliliter three-neck flask, and 240 milliliters of deionized water is added, and 0.0672 grams of silver nitrate solid is dissolved in 40 milliliters of deionized The water is then added to a three-necked flask, vacuumized and filled with nitrogen 3 times to maintain a nitrogen atmosphere. At room temperature, after fully stirring with mechanical stirring at 300 rpm for 3 hours, the emulsion was placed in an ice bath for 1 hour, and then 0.1656 grams of sodium borohydride solution dissolved in 10 milliliters of deionized water was quickly poured into the dripping solution In the funnel, drip into the three-necked flask solution at a rate of 2 seconds / drop. Keeping the ice bath and continuing to stir and react for 1.5 hours, stop the reaction, put the reaction product into a dialysis bag and dialyze for one week to obtain temperature-sensitive nanogel parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com