Binary working medium tower type solar power generating system

A tower type solar energy and power generation system technology, applied in solar thermal power generation, mechanical power generation with solar energy, machines/engines, etc., can solve the problem that the water working fluid system has no heat storage function, cannot guarantee continuous and stable gas supply, and molten salt systems Complex pipelines and other problems, to achieve the effect of improving system efficiency and power generation stability, low difficulty in operation and maintenance, and high technology maturity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

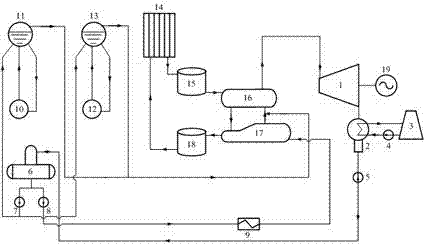

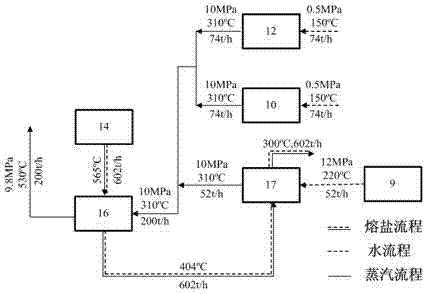

[0019] figure 1 It is a schematic diagram of the binary working medium tower solar power generation system described in the first embodiment. The components included in this embodiment are: steam turbine 1; condenser 2; cooling tower 3; circulating water pump 4; condensate pump 5; deaerator 6; Heater 10, 12; steam drum 11, 13 of hydraulic medium heat absorber; molten salt heat absorber 14; high temperature molten salt tank 15; molten salt superheater 16; evaporator 17; low temperature molten salt tank 18; generator 19 . Depend on figure 1 It can be seen that the exhaust steam of the steam turbine 1 is condensed into water in the condenser 2, and the condenser 2 forms a cooling water circuit with the cooling tower 3 and the circulating water pump 4, and the condensed water flows into the deaerator 6 through the condensate pump 5, and comes out from the deaerator The feed water is divided into three routes, one route enters the steam drum 11 of the hydraulic fluid heat absorb...

Embodiment 2

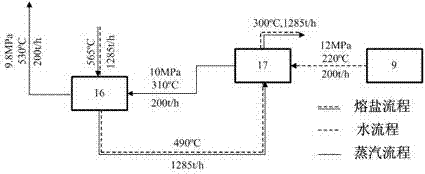

[0024] Figure 4 It is a schematic diagram of the binary working fluid tower solar power generation system described in the second embodiment. It can be seen from the figure that the difference between this embodiment and Embodiment 1 is that the hydraulic fluid heat absorbers 10, 12 are connected in series with the molten salt superheater 161, the evaporator 17 is connected in series with the molten salt superheater 162, and the molten salt superheater is used respectively. The devices 161 and 162 superheat the saturated steam generated by the water working medium heat absorbers 10 and 12 and the evaporator 17 . Now only the molten salt process is explained: the temperature of the molten salt rises sharply after absorbing heat in the molten salt heat absorber 14, and the high-temperature molten salt enters the molten salt superheater 161 and 162 respectively after passing through the high-temperature molten salt tank 15, and the hydraulic fluid The saturated steam generated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com