Micro-electro-mechanical system (MEMS)-based multi-channel tunable fiber laser and control method for same

A fiber laser and control method technology, applied in the field of lasers, can solve the problems of difficult to overcome polarization sensitivity of acousto-optic conversion, poor optical filtering effect, limited wavelength adjustment range, etc., to improve long-term work stability, low environmental requirements, Effect of Good Linear Polarization Characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing, through embodiment, further illustrate the present invention.

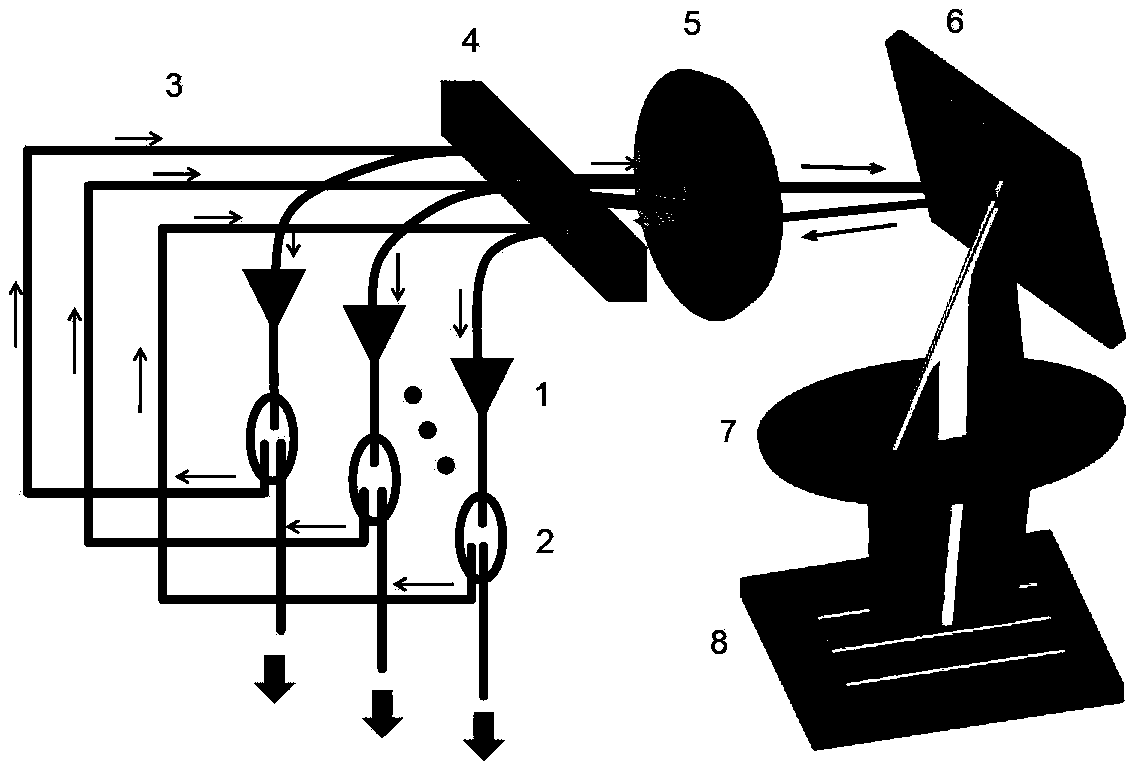

[0042] In this embodiment, the MEMS-based multi-channel tunable fiber laser of the present invention includes three fiber optic modules and one bulk optic module. Each of the three fiber optic modules includes a fiber amplifier 1, a fiber coupler 2, an optical fiber 3 and a double-pigtail collimator, and the three double-pigtail collimators form a double-pigtail collimator array 4; the bulk optical module Including a first lens 5, a grating 6, a second lens 7 and a MEMS processor 8, the MEMS processor is a very large scale integrated circuit provided with a MEMS chip, and a pixel array is integrated on the MEMS chip, and is aligned with three double pigtails The controller is correspondingly divided into three work areas, such as figure 1 shown.

[0043] Among them, the components in the three fiber optic modules all use polarization-maintaining components, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com