Preparation method of hydroxyl-terminated aqueous core shell emulsion for anticorrosive paint

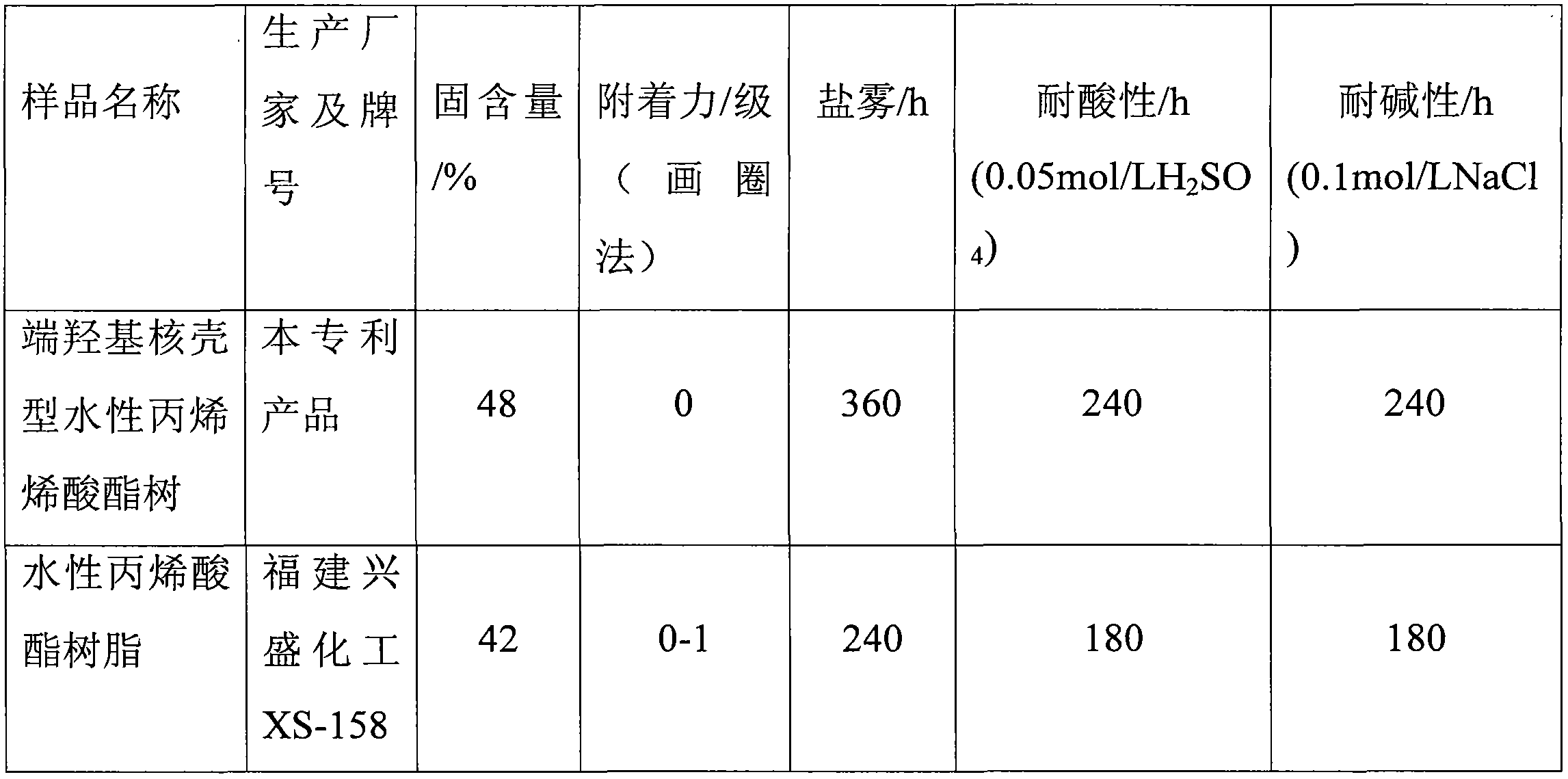

A core-shell emulsion and anti-corrosion coating technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of insufficient separation, weak mechanical properties and medium resistance, and achieve the goal of increasing solid content, high peel strength, and reducing VOC content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 1) Preparation of double bond-terminated linear polyurethane emulsion

[0052] Put 100 parts of PPG (molecular weight: 2000) into a three-neck flask, vacuum dehydrate at 100°C for 2 hours; cool down to 78°C, add 4.7 parts of NPG and 59.3 parts of IPDI, and keep it warm at 80°C for 3 hours; add DMPA after the reaction solution cools down to 75°C 9.86 parts and 10 parts of co-solvent acetone, keep warm at 78℃ for 0.5-1h, add 0.1 part of DBTDL, continue to react for 1.5-2h; cool down to 60℃, add 12.14 parts of HPMA, keep warm for 1.5h; after the reaction, cool down to 40℃ Add 25 parts of MMA for viscosity reduction, then add 7.4 parts of TEA and stir for 5 minutes, then add 370 parts of deionized water under high-speed stirring to disperse into an emulsion. After 10-15 minutes, slowly add 1.74 parts of hydrazine hydrate, 0.87 parts of ethylenediamine and deionized The mixture of 10 parts of water is chain-extended, and matured at 50°C for 1 hour to obtain a double-bond-ter...

Embodiment 2

[0058] 1) Preparation of double bond-terminated linear polyurethane

[0059] Put 100 parts of PTMG (molecular weight 2000) into a three-necked flask, dehydrate in vacuum at 100°C for 2 hours; cool down to 75°C, add 4.7 parts of NPG and 46.3 parts of TDI, and keep warm at 80°C for 3 hours; after the reaction solution cools to 75°C, add DMPA 9.86 10 parts of acetone and 10 parts of acetone, 78 ℃ heat preservation reaction 0.5-1h, add DBTDL 0.1 part, continue to react for 1.5-2h; after cooling down to 60 ℃, add 12.14 parts of HPMA, heat preservation reaction 1.5h; after the reaction, cool down to 40 ℃ and add 25 parts of MMA for viscosity reduction, then add 7.4 parts of TEA and stir for 5 minutes, then add 370 parts of deionized water under high-speed stirring to disperse into an emulsion, and slowly add 4 parts of ADH, 0.87 parts of ethylenediamine and 10 parts of deionized water after 10-15 minutes part of the mixture for chain extension, and aging at 50°C for 1 hour to obtain...

Embodiment 3

[0065] 1) Preparation of double bond-terminated linear polyurethane

[0066] Put 100 parts of PCL (molecular weight: 2000) into a three-necked flask, dehydrate under vacuum at 100°C for 2 hours; cool down to 80°C, add 4.7 parts of NPG and 59.1 parts of IPDI, and keep warm at 80°C for 3 hours; after cooling down to 75°C, add 9.86 parts of DMPA and auxiliary 10 parts of solvent acetone, 78 ℃ heat preservation reaction for 0.5-1h, dropwise add 0.15 parts of DBTDL to continue the reaction for 1.5-2h; after cooling down to 60 ℃, add 12 parts of HPMA, heat preservation reaction for 1.5h; After 10-15 minutes, slowly add 1.74 parts of hydrazine hydrate, 0.87 parts of ethylenediamine and 20 parts of deionized water to expand the mixture. chain, cured at 50°C for 1 hour to obtain a double-bond-terminated linear polyurethane emulsion.

[0067] 2) Preparation of core layer polyurethane modified acrylate composite emulsion

[0068] Add 4 parts of SDS, 4 parts of Pingpingjia, 35 parts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com