Method for microalgae coupling of culturing and recovery to quickly accumulate algal oil

A technology of microalgae culture and microalgae culture solution, which is applied in the field of microalgae bioenergy, can solve the problems of high energy consumption for harvesting, waste of culture salt and water, increase of culture cost, etc., to simplify the operation process, shorten production time, The effect of saving cultivation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

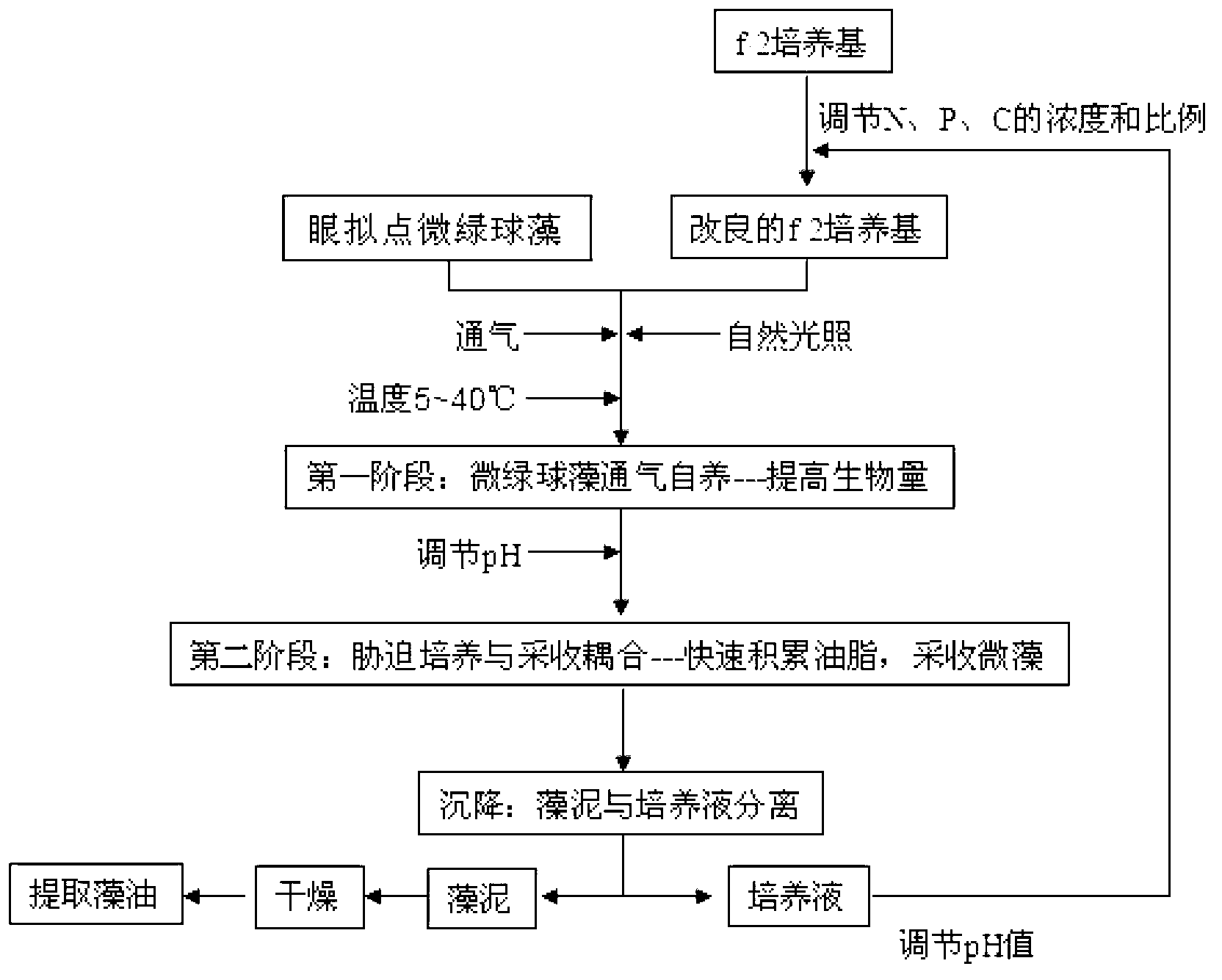

Method used

Image

Examples

Embodiment 1

[0041] The concentration of nitrogen and the optimization of nitrogen-phosphorus ratio in the improved F / 2 culture solution of embodiment 1

[0042] Adding NaNO to basal F / 2 medium 3 And adjust the mass ratio of nitrogen and phosphorus to obtain the improved F / 2 culture solution, divide the experiment into 11 groups:

[0043] Group 1 is the control group, and the culture medium is the basic F / 2 culture medium, that is, NaNO 3 The final concentration is 75mg / L, NaH 2 PO 4 2H 2 The final concentration of O is 5 mg / L, and the corresponding nitrogen to phosphorus mass ratio is 12:1;

[0044] Group 2~Group 11 is the experimental group, and the culture medium of Group 2~Group 7 is the improved F / 2 culture medium, NaNO 3 The final concentrations are 25, 75, 225, 450, 900, 1350 mg / L, corresponding to NaH 2 PO 4 2H 2 The final concentrations of O were 5, 15, 45, 90, 180, and 270 mg / L, respectively, to ensure that the mass ratio of nitrogen and phosphorus was 4:1. The culture m...

Embodiment 2

[0051] Example 2 Condition optimization of the coupling process of Nannochloropsis pH stress oil production and pH flocculation recovery

[0052] Adjustment of NaNO in basal F / 2 medium 3 The final concentration is 225mg / L, and the mass ratio of nitrogen and phosphorus is 4:1 (corresponding to NaH 2 PO 4 2H 2 O final concentration was 45mg / L), and improved F / 2 culture solution was obtained.

[0053] (1) Inoculate fresh cells of Nannochloropsis ophthalmica into the above-mentioned modified F / 2 culture medium at an inoculum volume fraction of 5% at a culture temperature of 25-30°C, under natural light, and continuously inflate with air for 3 days to After the logarithmic phase, it was cultured for another 15 days under the same conditions to obtain the algae liquid. Take 1000mL of algae liquid, adjust the pH of the algae liquid to 11, let it stand at room temperature (25~30°C) for 3 days to separate the algae liquid, obtain the supernatant and the lower layer of precipitation...

Embodiment 3

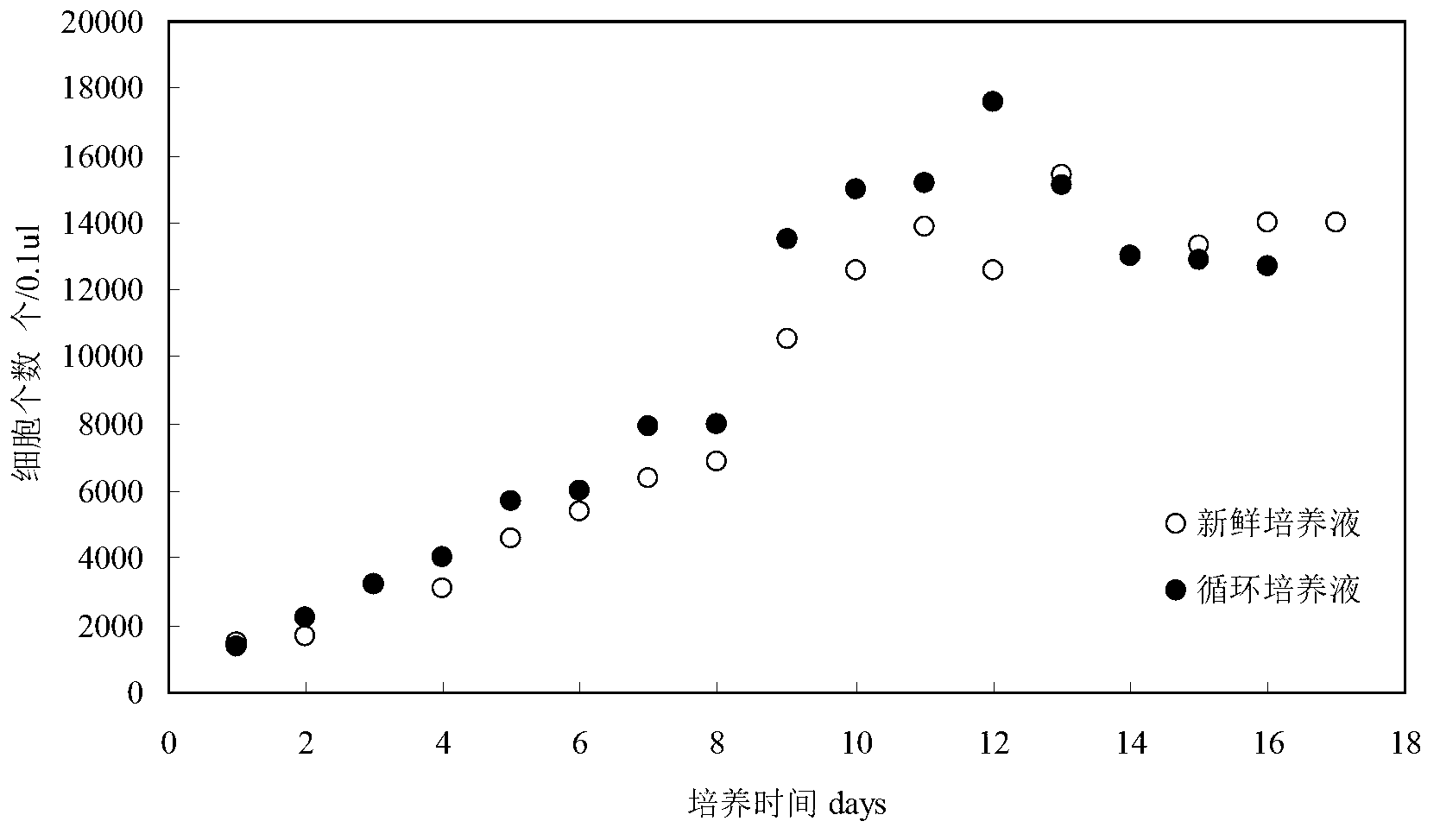

[0067] Example 3 pH flocculation The supernatant after harvesting microalgae is recycled for the cultivation of microalgae

[0068] Adjustment of NaNO in basal F / 2 medium 3 The final concentration is 225mg / L, and the mass ratio of nitrogen and phosphorus is 4:1 (corresponding to NaH 2 PO 4 2H 2 O final concentration was 45mg / L), and improved F / 2 culture solution was obtained.

[0069] (1) Inoculate fresh cells of Nannochloropsis ophthalmica into the above-mentioned modified F / 2 culture medium at an inoculum volume fraction of 5% at a culture temperature of 25-30°C, under natural light, and continuously inflate with air for 3 days to After the logarithmic phase, it was cultured for another 15 days under the same conditions to obtain the algae liquid. Adjust the pH of the algae solution to 11, and let it stand at room temperature (25~30°C) for 3 days to separate the algae solution to obtain the supernatant and the lower layer of sediment. ), and recycle the supernatant.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com