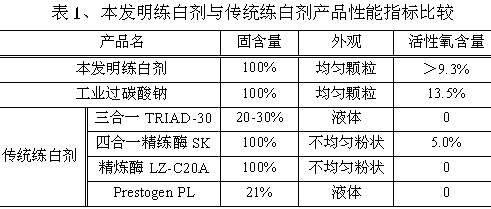

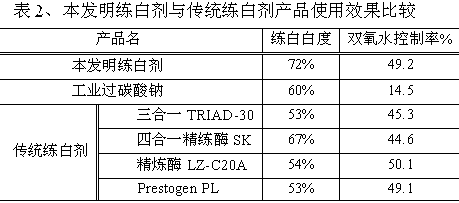

Short-process pre-treatment scouring agent for textile and preparation method thereof

A short process and textile technology, applied in the field of whitening agent, can solve the problems of waste of water resources and energy, consumption of large chemicals, incomplete compatibility, etc., and achieve water and energy saving, wide application range, good economy and The effect of social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method for a short-process pretreatment whitening agent for textiles, comprising the steps of:

[0023] 1) Add 350kg of sodium carbonate solution with a mass concentration of 7% into the reaction kettle, then add 100kg of sodium metasilicate, 50kg of EDTA-2Na and 50kg of surfactant, mix evenly, and then add it at a speed of 500r / min and a temperature of 20 Under the condition of ℃, add 573kg of alkali agent and 650kg of hydrogen peroxide with a mass concentration of 35% to the reaction kettle within 1 hour. After the feeding is completed, precipitate in the sedimentation tank to crystallize the semi-finished whitening agent;

[0024] 2) Transfer the semi-product of whitening agent produced by reaction crystallization into a centrifuge for 30 minutes, and dry it with cold wind. At the same time, spray 100kg of coating agent for coating. The semi-finished product after coating is sent to the fluidized bed for drying The machine is dried at 90°C, and the drie...

Embodiment 2

[0026] A preparation method for a short-process pretreatment whitening agent for textiles, comprising the steps of:

[0027] 1) Add 350kg of sodium carbonate solution with a mass concentration of 7% into the reaction kettle, then add 100kg of sodium metasilicate, 50kg of EDTA-2Na and 50kg of surfactant, mix evenly, and then add it at a speed of 500r / min and a temperature of 20 Under the condition of ℃, add 565kg of alkali agent and 673kg of hydrogen peroxide with a mass concentration of 35% into the reaction kettle within 1 hour. After the feeding is completed, precipitate in the sedimentation tank to crystallize the semi-finished whitening agent;

[0028] 2) Transfer the semi-product of whitening agent produced by reaction crystallization into a centrifuge for 30 minutes, and dry it with cold wind. At the same time, spray 100kg of coating agent for coating. The semi-finished product after coating is sent to the fluidized bed for drying The machine is dried at 85°C, and the dr...

Embodiment 3

[0030] A preparation method for a short-process pretreatment whitening agent for textiles, comprising the steps of:

[0031] 1) Add 350kg of sodium carbonate solution with a mass concentration of 7% into the reaction kettle, then add 100kg of sodium metasilicate, 50kg of EDTA-2Na and 50kg of surfactant, mix evenly, and then mix it at a speed of 500r / min and a temperature of 15 Under the condition of ℃, 556kg of alkali agent and 696kg of hydrogen peroxide with a mass concentration of 35% were fed into the reaction kettle within 1 hour. After the feeding was completed, it was precipitated in the sedimentation tank to crystallize the semi-finished whitening agent;

[0032] 2) Transfer the semi-product of whitening agent produced by reaction crystallization into a centrifuge for 30 minutes, and dry it with cold wind. At the same time, spray 100kg of coating agent for coating. The semi-finished product after coating is sent to the fluidized bed for drying The machine is dried at 95...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com