Cigarette paper additive for reducing harmful ingredients of cigarette mainstream smoke and application thereof

A technology for mainstream smoke and harmful components of cigarettes, applied in the directions of non-fiber pulp addition, papermaking, textiles and papermaking, etc., can solve the problems of cigarettes with insignificant harmful effects, high hemicellulose content, and inability to achieve application, etc. The effect of high safety and practicability, a wide range of sources, and a simple and easy process method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

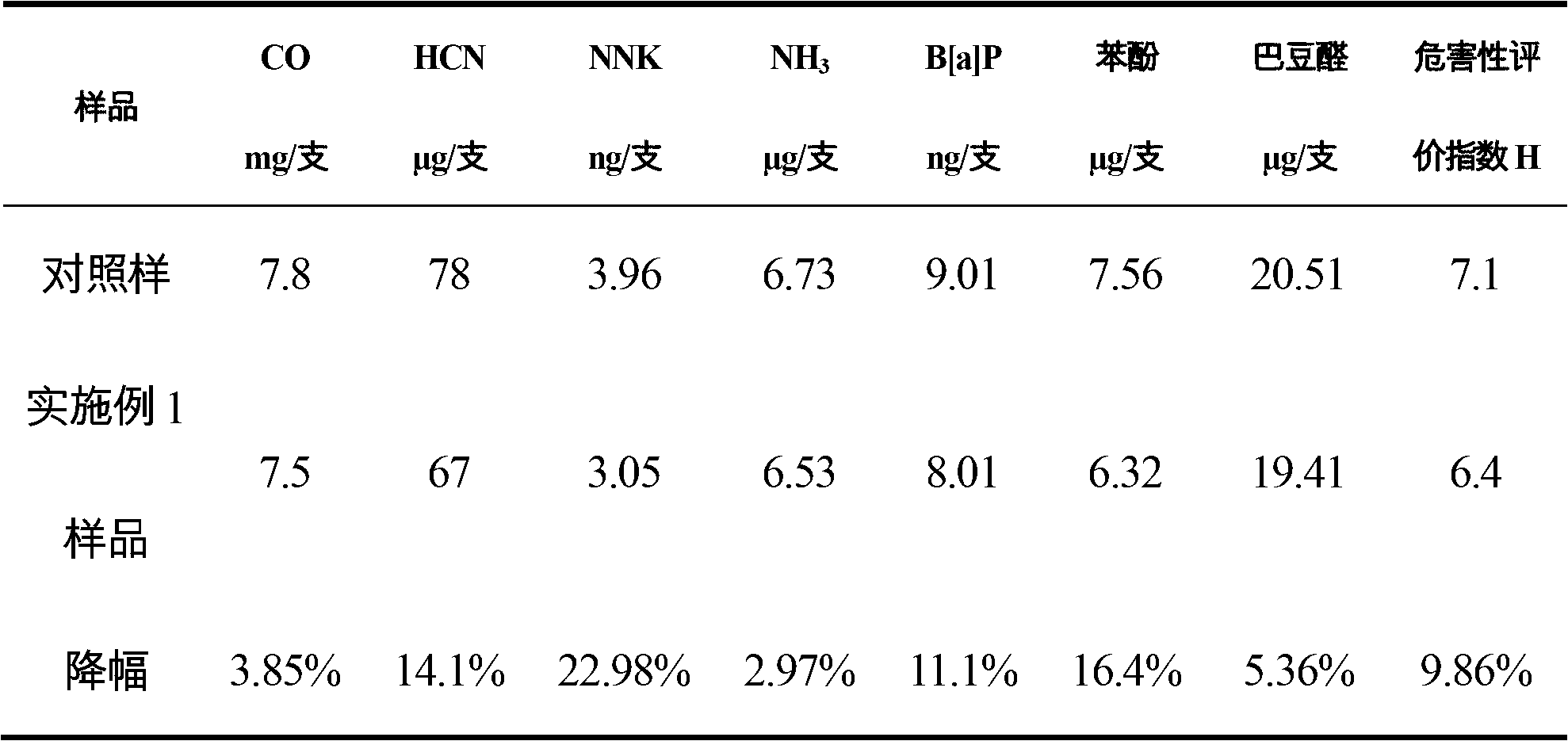

[0035] Produced according to the tobacco fiber cigarette paper process, control the index of tobacco fiber cigarette paper: quantitative: 32.0g / m 2;Air permeability: 60CU. Prepare 5% flue-cured tobacco extract, 5% green tea extract, 30% mixture of benzoic acid and lactic acid, 60% mixture of potassium carbonate, potassium citrate, potassium tartrate, sodium acetate, sodium phosphate, and sodium citrate as a mixed solution. In the paper production process, additives are added at 1% of the weight of cigarette paper by coating method, and the experimental samples of tobacco fiber cigarette paper are prepared. According to the same cigarette paper index and production process, a control sample of tobacco fiber cigarette paper was prepared without adding additives. The above percentages are percentages by weight.

[0036] The above-mentioned cigarette paper samples and control samples were used to prepare cigarettes on a certain brand of cigarettes. The seven harmful components ...

Embodiment 2

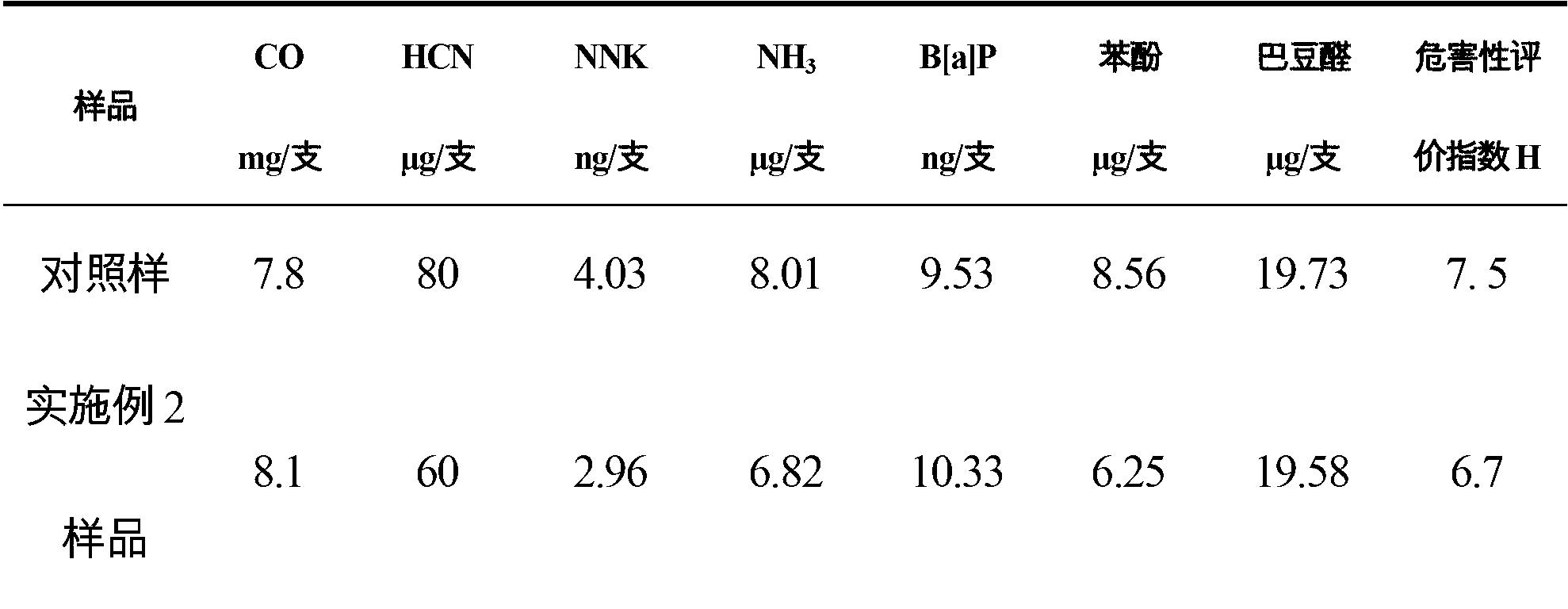

[0041] Produced according to the tobacco fiber cigarette paper process, control the index of tobacco fiber cigarette paper: quantitative: 35.0g / m 2 ;Air permeability: 70CU. Prepare 20% Burley tobacco extract, 18% Puer tea extract, 10% mixture of malic acid, tartaric acid, citric acid, mixture of potassium sorbate, potassium citrate, potassium acetate, sodium acetate, sodium citrate, and sodium carbonate 52% is a mixed solution, and in the cigarette paper production process, additives are added at 4% of the weight of the cigarette paper by coating to prepare a tobacco fiber cigarette paper test sample. According to the same cigarette paper index and production process, a tobacco fiber cigarette paper control sample was prepared without adding additives.

[0042] The above-mentioned cigarette paper samples and control samples were used to prepare cigarettes on a certain brand of cigarettes. Detect seven harmful components of cigarettes, the results show that compared with the ...

Embodiment 3

[0047] Produced according to the tobacco fiber cigarette paper process, control the index of tobacco fiber cigarette paper: quantitative: 28.0g / m 2 ;Air permeability: 60CU. Prepare flue-cured tobacco and oriental tobacco mixed extract 20%, green tea extract 20%, benzoic acid, lactic acid, malic acid, tartaric acid, citric acid mixture 30%, potassium carbonate, potassium citrate, sodium acetate, sodium phosphate, lemon 30% of the mixture of sodium bicarbonate is a mixed solution. In the cigarette paper production process, the auxiliary agent is added by coating at 2% of the weight of the cigarette paper, and the tobacco fiber cigarette paper test sample is prepared. According to the same cigarette paper index and production process, a tobacco fiber cigarette paper control sample was prepared without adding additives.

[0048] The above-mentioned cigarette paper samples and control samples were used to prepare cigarettes on a certain brand of cigarettes. Detect seven harmful c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gas permeability | aaaaa | aaaaa |

| gas permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com