Mixed crystal/solid alkali combined catalyst and preparation method thereof

A technology of combining catalysts and mixed crystal solid bases, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Limitation, late start, high cost and other problems, to achieve the effect of improving product purity and product yield, easy separation, and improving conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025]

[0026]

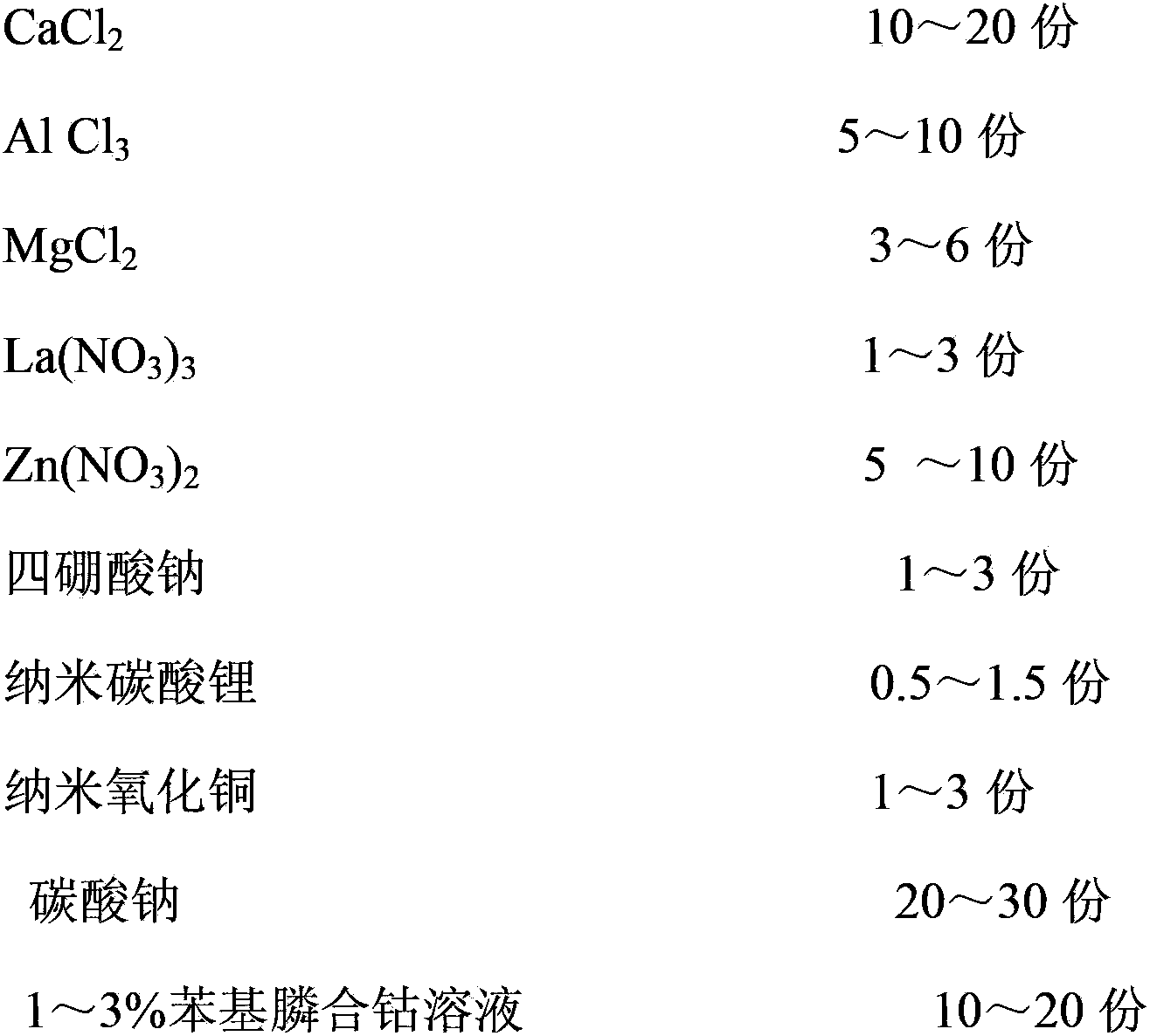

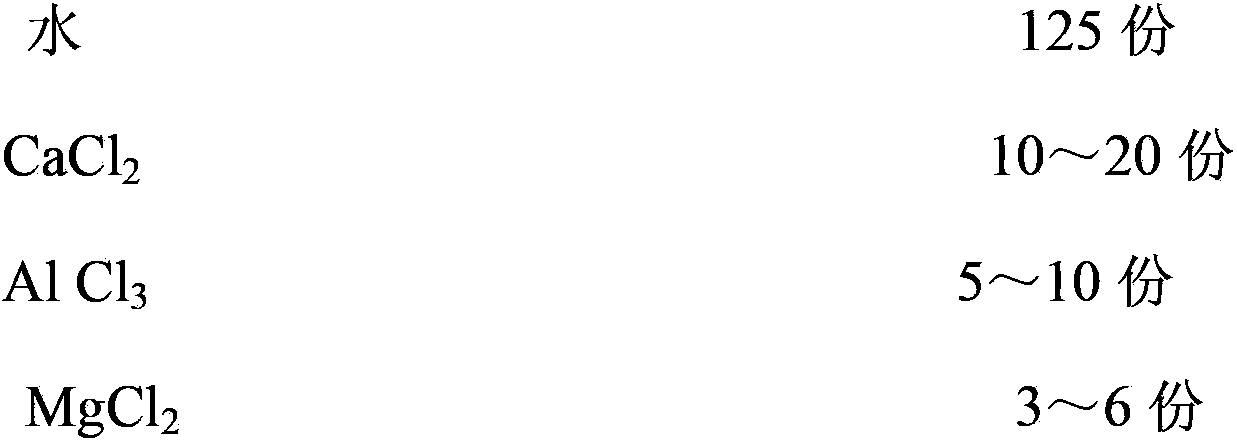

[0027] (1). First put CaCl 2 , Al Cl 3 and MgCl 2 Mix and dissolve into 125 parts of deionized water, La(NO 3 ) 3 Mix and dissolve Zn(NO3)2 into 125 parts of deionized water, dissolve sodium carbonate into 125 parts of deionized water, add 125 parts of deionized water into the reaction kettle, then add sodium tetraborate, nano-lithium carbonate and nano-copper oxide , turn on the high-speed disperser at 1500 rpm, control the temperature of all solutions at 10°C, and add CaCl 2 , Al Cl 3 and MgCl 2 Mixed solution, La(NO 3 ) 3 and Zn(NO 3 ) 2 Add the mixed solution and sodium carbonate solution into the reaction kettle dropwise, and the dropwise addition is completed within 60 minutes. Stir at a high speed for 3 hours at a temperature of 10°C, then raise the temperature to 60°C, continue stirring at a high speed for 3 hours, and promote crystal growth by raising the temperature, stop Stir, lower to normal temperature, and stand still for 24 hour...

Embodiment 2

[0031]

[0032] (1). First put CaCl 2 , Al Cl 3 and MgCl 2 Mix and dissolve into 125 parts of deionized water, La(NO 3 ) 3 and Zn(NO 3 ) 2 Mix and dissolve into 125 parts of deionized water, dissolve sodium carbonate into 125 parts of deionized water, add 125 parts of deionized water into the reaction kettle, then add sodium tetraborate, nano-lithium carbonate and nano-copper oxide, and turn on the high-speed disperser 2000 rev / min, the temperature of all solutions was controlled at 15°C, while the CaCl 2 , Al Cl 3 and MgCl 2 mixed solution, La(NO 3 ) 3 and Zn(NO 3 ) 2 The mixed solution and the sodium carbonate solution were added dropwise into the reaction kettle, and the dropwise addition was completed within 30 minutes. Stir at a high speed for 2 hours at a temperature of 15°C, then raise the temperature to 50°C, and continue to stir at a high speed for 3 hours, and promote crystal growth by heating up. Stop stirring, lower to normal temperature, and stand s...

Embodiment 3

[0036]

[0037] (1). First put CaCl 2 , Al Cl 3 and MgCl 2 Mix and dissolve in 125 parts deionized water to La(NO 3 ) 3 and Zn(NO 3 ) 2 Mix and dissolve into 125 parts of deionized water, dissolve sodium carbonate into 125 parts of deionized water, add 125 parts of deionized water into the reaction kettle, then add sodium tetraborate, nano-lithium carbonate and nano-copper oxide, and turn on the high-speed disperser 1750 rev / min, control the temperature of all solutions at 13°C, and simultaneously add CaCl 2 , Al Cl 3 and MgCl 2 Mixed solution, La(NO 3 ) 3 and Zn(NO 3 ) 2 The mixed solution and sodium carbonate solution were added dropwise into the reaction kettle together, and the dropwise addition was completed within 45 minutes. Stir at a high speed for 2.5 hours at a temperature of 13°C, then raise the temperature to 55°C, and continue to stir at a high speed for 2.5 hours to promote crystal growth by raising the temperature. Stop stirring, lower to normal t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com