Catalyst for preparation of acetic acid and methyl acetate through carbonylation of methanol and preparation method thereof

A methanol carbonylation and methyl acetate technology, applied in the preparation of carbon monoxide or formate reaction, chemical instruments and methods, carbon monoxide reaction to prepare carboxylic acid, etc., can solve the strong corrosion of halogen accelerators, increase production costs, corrosion equipment, etc. problems, to achieve high catalyst selectivity, improve catalytic activity, and improve the effect of crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

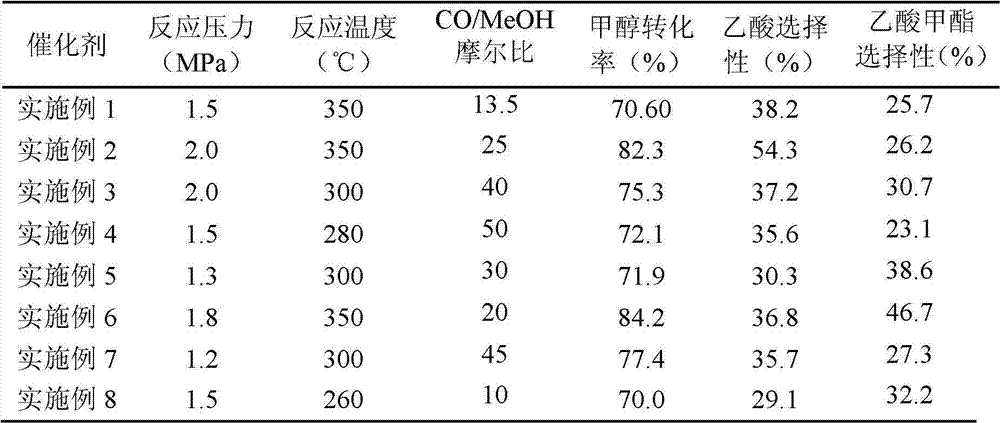

Examples

Embodiment 1

[0029] Take by weighing 10g mordenite (commercially available), 0.63g CuCl 2 2H 2 O. First, the HMOR was pre-fired at 500°C for 3 hours, cooled, and sealed for later use. The copper chloride weighed above was dissolved in 50 ml of absolute ethanol, and magnetically stirred at room temperature until completely dissolved. Then pour 10g of HMOR into the dissolved solution, stir until the mordenite is evenly dispersed, then start to heat up to 90°C, and continue stirring until the ethanol evaporates completely. The resulting solid was dried overnight in an oven at 120°C. in N 2 Under atmosphere, the dried solid was calcined at 350°C for 4h. Get 5% CuCl 2 / HMOR catalyst, where CuCl 2 The loading amount is 5%.

Embodiment 2

[0031] Take by weighing 10g mordenite (commercially available), 0.63g CuCl 2 2H 2 O and 1.84 g NiCl 2 ·6H 2O. First, the HMOR was pre-fired at 300°C for 2 hours, cooled, and sealed for later use. The copper chloride and nickel chloride weighed above were dissolved in 50 ml of absolute ethanol, and magnetically stirred at room temperature until completely dissolved. Then pour 10g of HMOR into the dissolved solution, stir until the mordenite is evenly dispersed, then start to heat up to 90°C, and continue stirring until the ethanol evaporates completely. The resulting solid was dried overnight in an oven at 90°C. in N 2 Under atmosphere, the dried solid was calcined at 300°C for 3h. Get 5% CuCl 2 -10%NiCl 2 / HMOR catalyst, where CuCl 2 The loading is 5%, NiCl 2 The loading amount is 10%. .

Embodiment 3

[0033] Take by weighing 10g mordenite (commercially available), 0.92g NiCl 2 ·6H 2 O and 1.88g CuCl 2 2H 2 O. First, the HMOR was pre-fired at 500°C for 3 hours, cooled, and sealed for later use. Dissolve the nickel chloride and copper chloride weighed above in 50 ml of absolute ethanol, and stir magnetically at room temperature until completely dissolved. Then pour 10g of HMOR into the dissolved solution, stir until the mordenite is evenly dispersed, then start to heat up to 90°C, and continue stirring until the ethanol evaporates completely. The resulting solid was dried overnight in an oven at 120°C. in N 2 Under atmosphere, the dried solid was calcined at 350°C for 4h. Catalyst 15% CuCl 2 -5%NiCl 2 / HMOR, where CuCl 2 The loading is 15%, NiCl 2 The loading amount is 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com