Room temperature curable organopolysiloxane composition and gas separation membrane

A polysiloxane and organo-based technology, applied in the field of room temperature curable organopolysiloxane compositions, can solve problems such as not mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0104] Preparation of the composition

[0105] The composition of the present invention can be prepared by uniformly mixing components (I) to (IV) and other optionally added components.

[0106] Application of the composition

[0107] The compositions of the present invention provide gas separation membranes with significantly improved gas permeability, gas selectivity and other functions, in particular improved permselectivity of hydrogen from gas mixtures, permselectivity of oxygen from air, carbon dioxide Permselectivity from greenhouse gases and methane from natural gas, etc., because it contains silica nanoparticles with a surface modified with a branched structure between branches Provides free volume, especially for gas permeability.

[0108] Based on this performance, the product of the present invention can be used to selectively permeate hydrogen from mixed gases, recover oxygen from air, provide high-concentration oxygen for combustion systems, separate and recove...

Embodiment 1

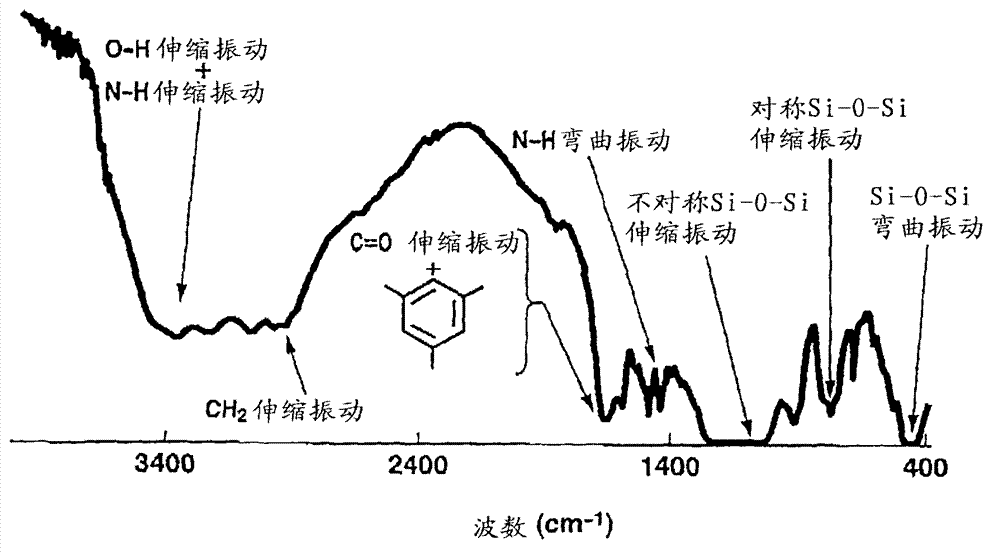

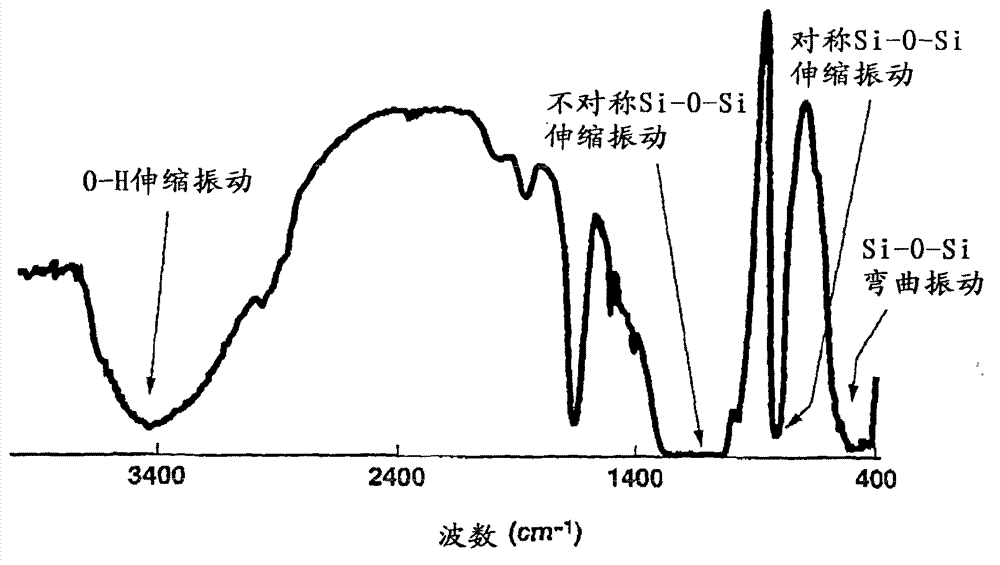

[0144] Fabrication of Organic-Inorganic Hybrid Gas Separation Membrane Using Polydimethylsiloxane and Colloidal Silica Surface Modified with Hyperbranched Structure

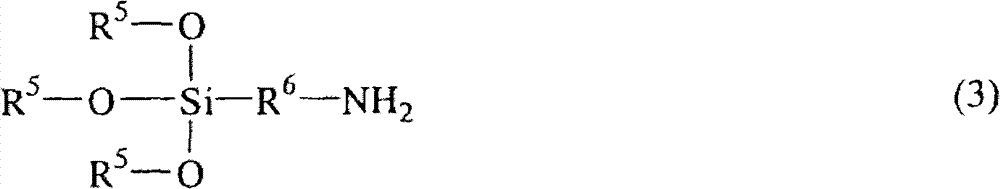

[0145] The uncrosslinked polydimethylsiloxane prepared in 1.5g of synthesis example 1 was dissolved in 6.921ml of toluene, and the surface of the prepared in synthesis example 5 was modified with hyperbranched structure 6 (3 generations) Colloidal dimethicone Silica was added to the polymer solution so that the polymer content was 20% by weight. After ultrasonication for 1 hour, the polymer solution was stirred overnight at a stirring rate of 1200 rpm, and after adding 0.25 g of vinyltrimethylethylketoximosilane (crosslinking agent) and γ-aminopropyltriethoxysilane After 10:1 mixture (weight ratio), the mixture was cast onto Teflon (registered trademark) dishes. The Teflon (registered trademark) dish was left at room temperature for several days to prepare a hybrid film. The resulting hybrid film was dried unde...

Embodiment 2

[0149] Fabrication of Organic-Inorganic Hybrid Gas Separation Membrane Using Polydimethylsiloxane and Colloidal Silica with Hyperbranched Structure Modified Surface

[0150] Repeat the process of Example 1, add colloidal silica with hyperbranched structure 4 (1 generation) modified surface obtained in Synthesis Example 5 as colloidal silica with hyperbranched structure modified surface to prepare organic-inorganic Hybrid gas separation membrane. The gas permeability of the resulting hybrid membrane was measured by repeating the procedure of Example 1. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com