Composite anthraquinone-type cobalt blue reactive dye

A reactive dye and anthraquinone-based technology, applied in organic dyes, dyeing methods, textiles, and papermaking, can solve problems such as low color fastness and poor lifting power, and improve product quality, washability, and The effect of dyeing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

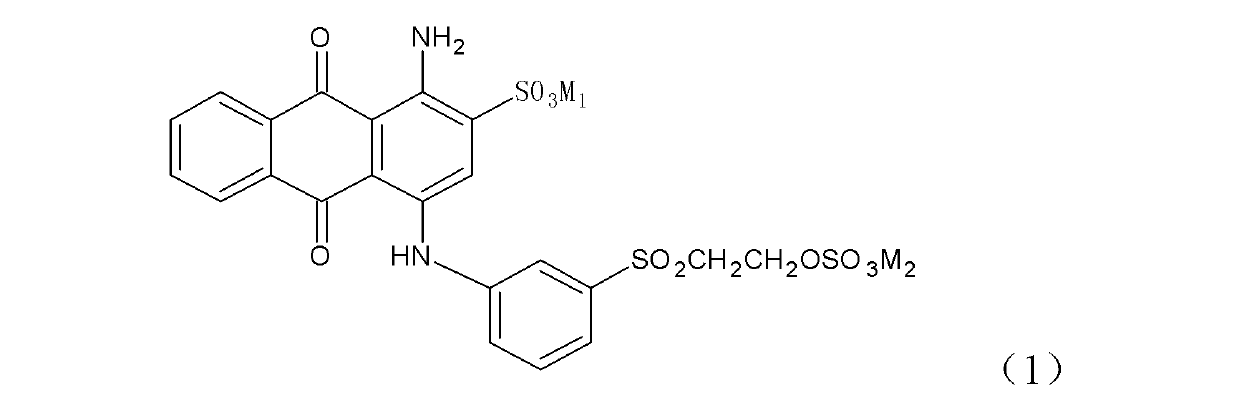

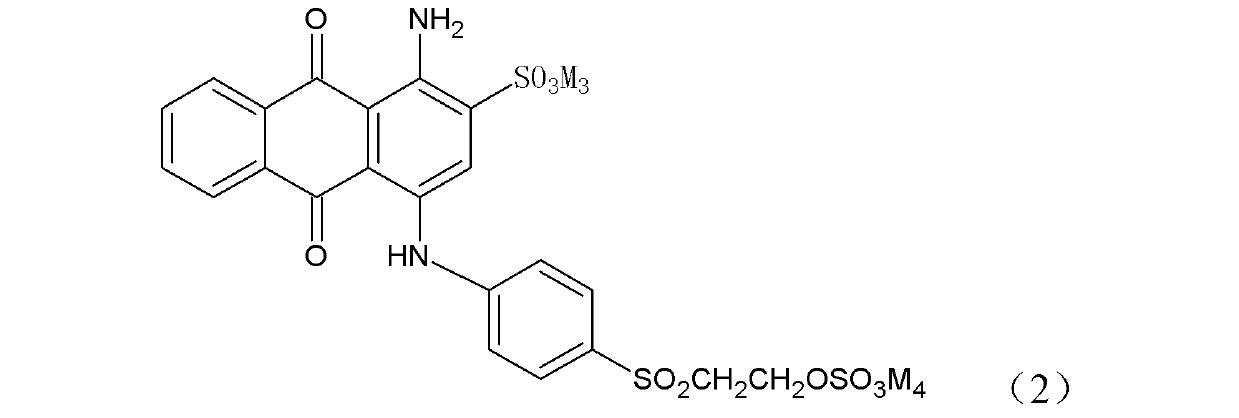

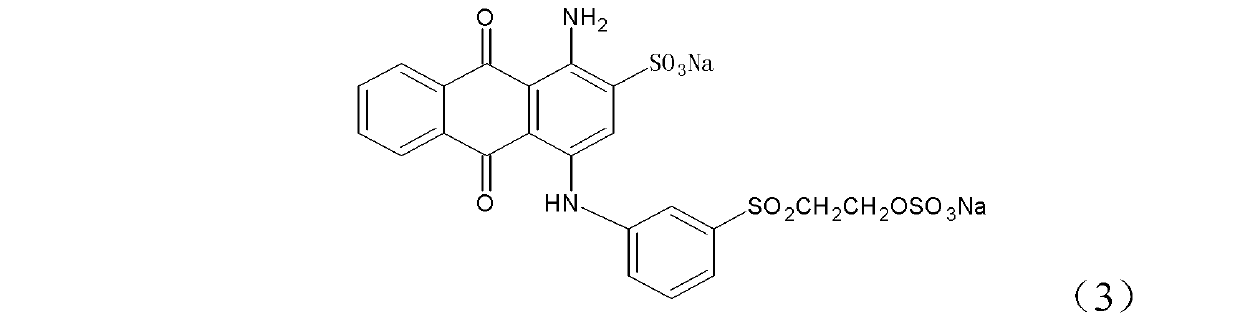

Image

Examples

Embodiment 1

[0017] Synthesis of reactive dye A:

[0018] 78.6 g of bromonic acid, 42.5 g of amino oil (m-(β-hydroxyethylsulfone) aniline) and 250 g of water were beaten at 90-95°C for 1 hour. Then lower the temperature to 60-65°C, add 45g of baking soda, then add 1g of copper powder and 2g of cuprous chloride at 60-65°C, keep the temperature for 15 hours, and take samples for liquid chromatography analysis. as the end point. Pour the material into 800g water for beating for 1 hour, and use 40-50% sulfuric acid to acidify the pH value to 1-2. After stabilizing the pH value at 1-2 for 30 minutes, carry out suction filtration, dry and dry the filter cake at 80-100°C, and control the moisture content to ≤1%. The synthetic reaction formula of chromophore is shown in formula (5) below.

[0019]

[0020] After crushing the dried 110g filter cake, slowly add it to 500g 98% concentrated sulfuric acid for esterification reaction, react at room temperature for 15 hours, take a sample for liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com