Surface mount adhesive for surface mount technology and preparation method of surface mount adhesive

A surface mount technology and patch adhesive technology, applied in the direction of adhesives, epoxy resin glue, film/sheet adhesive, etc., to achieve the effect of low curing temperature, good bonding effect, and short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

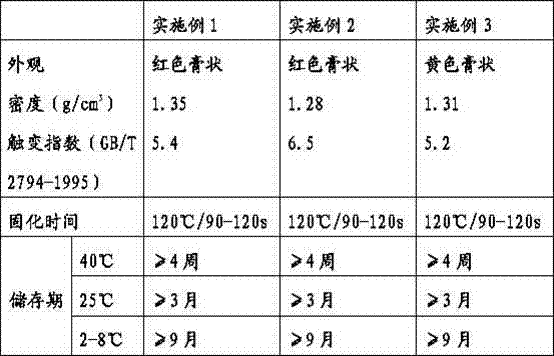

Examples

Embodiment 1

[0025] Weigh raw materials according to the following parts by mass

[0026] Epoxy resin: EP-828EL 40 parts

[0027] Reactive diluent: glycidyl ether of tertiary carbonic acid 9.5 parts

[0028] Stabilizer: 0.1 parts of salicylic acid

[0029] Curing agent: FXR-1020 10 parts

[0030] Curing accelerator PN-23 5 parts

[0031] Thixotropic agent R202 5 parts

[0032] Filler: microsilica powder 20 parts

[0034] Pigment: 0.4 parts of permanent red

[0035] First add epoxy resin, reactive diluent, stabilizer and pigment into the double planetary stirring tank, stir for 20 minutes under vacuum, then add thixotropic agent and filler, mix well and stir at high speed under vacuum for 2 hours, and finally Add curing agent and curing accelerator and stir evenly, then vacuumize and stir at low speed for 2-3 hours before discharging.

[0036]

Embodiment 2

[0038] Weigh raw materials according to the following parts by mass

[0039] Epoxy resin: DER331 60 parts

[0040] Reactive diluent: tertiary carbonic acid glycidyl ether 2 parts

[0041] Stabilizer: 1 part of benzoic acid

[0042] Curing agent: EH-4360S 15 parts

[0043] Curing accelerator: MC120D 1 part

[0044] Thixotropic agent: TS720 10 parts

[0045] Filler: microsilica powder 10 parts

[0046] Pigment: 1 part of permanent red

[0047] First add epoxy resin, reactive diluent, stabilizer, and pigment into the double planetary stirring tank, stir for 25 minutes under vacuum, then add thixotropic agent and filler, mix well, stir at high speed under vacuum for 2.5 hours, and finally Add curing agent and curing accelerator in turn and stir evenly, then vacuumize and stir at low speed for 3 hours, then discharge.

[0048]

Embodiment 3

[0050] Weigh raw materials according to the following parts by mass

[0051] Epoxy resin: E51 43.4 parts

[0052] Reactive diluent: 3 parts of tert-butylphenyl glycidyl ether

[0053] Stabilizer: 0.5 parts of lactic acid

[0054] Curing agent: EH-5031S 30 parts

[0055] Curing accelerator: PN-40 2 parts

[0056] Thixotropic agent: R202 6 parts

[0057] Filler: calcium carbonate 15 parts

[0058] Pigment: permanent yellow 0.1 parts

[0059] First add epoxy resin, active diluent, stabilizer, and pigment into the double planetary stirring tank, stir for 30 minutes under vacuum, then add thixotropic agent and filler, mix well, stir at high speed under vacuum for 3 hours, and finally Add curing agent and curing accelerator and stir evenly, then vacuumize and stir at low speed for 2.5 hours before discharging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com