Aqueous curable binder composition

A technology of carbohydrates and compositions, applied in adhesive types, polysaccharide adhesives, starch adhesives, etc., can solve the problems of unsuitable flexible substrates, hard adhesives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: latex modifier emulsion synthesis process

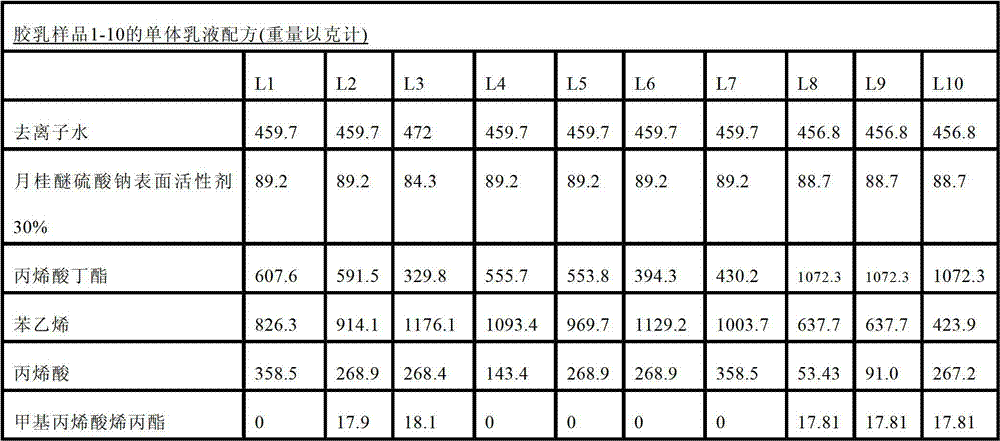

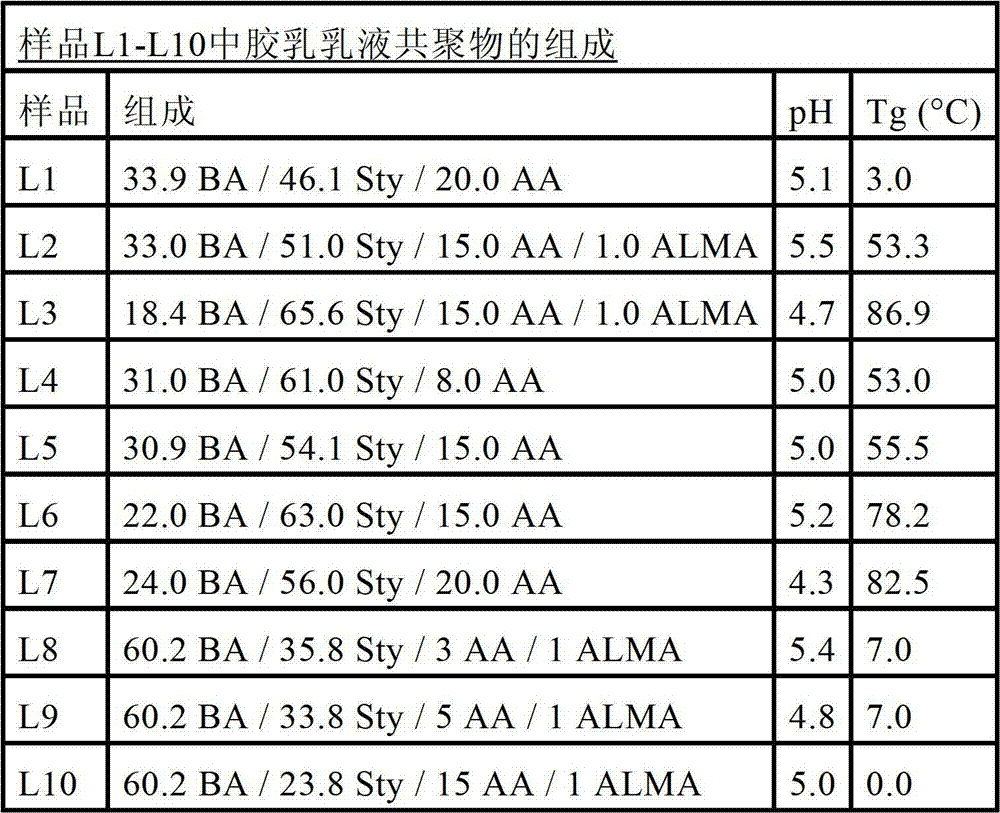

[0051]A round bottom flask equipped with a paddle stir bar, thermocouple, nitrogen inlet, and reflux condenser was charged with deionized water and inhibitors and heated. Upon heating to a certain temperature, sodium laurel ether sulphate surfactant dissolved in deionized water was added to the flask, followed by a mixture of sodium hydroxide dissolved in deionized water. A monomer emulsion was prepared according to the formulation in Table 1, sample L1 consisted of butyl acrylate, acrylic acid and sodium lauryl ether sulfate surfactant (30%) in deionized water. An additional portion of the monomer emulsion was added to the flask, followed by ammonium persulfate dissolved in deionized water. After the maximum exotherm was reached, the remaining monomer emulsion was gradually added in addition to a separate solution of ammonium persulfate dissolved in deionized water while maintaining the same temperature. Afte...

Embodiment 2

[0057] Example 2: Adhesive Formulation

[0058] 1. Preparation of Raw Adhesive

[0059] Each series of raw binders comprising maltodextrin and polyacid crosslinker (crosslinker) was prepared using the following method. First, add maltodextrin to the water in the container, and use a desktop Lightnin Mixer (Lightnin Mixer) to stir until it is completely dissolved. A crosslinking agent (citric acid, maleic acid or polyacrylic acid) is then added to the vessel while stirring. After the crosslinker is completely dissolved, a curing catalyst (sodium hypophosphite) is optionally added and the mixture is stirred until completely dissolved. The total solids of the raw binder was about 50% by weight.

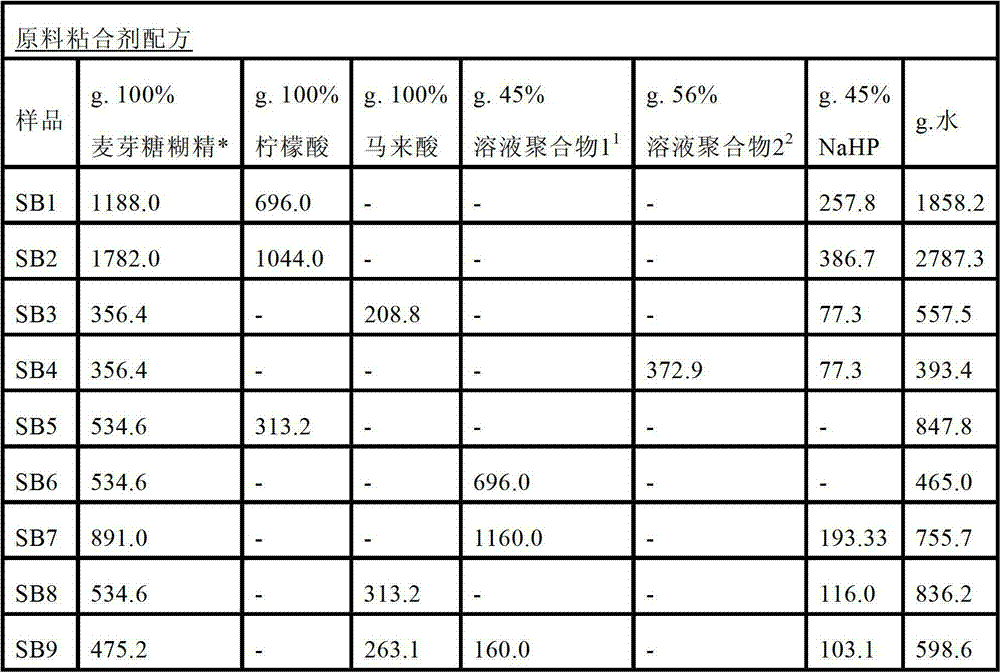

[0060] 2. Examples of Adhesive Formulations

[0061] A raw adhesive formulation was prepared as shown in Table 3 below using citric acid as the crosslinker and sodium hypophosphite as the curing catalyst.

[0062] table 3

[0063]

[0064] * Maltodextrin: purchased from Spect...

Embodiment 3

[0081] Embodiment 3: test method

[0082] 1. Handsheet preparation method using glass fiber / white system 1

[0083] Use Johns Manville 137Standard, 3.2 cm long (1 1 / 4 inches) of sized glass chop to make a fiberglass nonwoven handsheet (handsheet), using approximately 7.6 grams of glass fiber per sheet (0.82 kg / 9.3 m2; 1.8 lb / 100 sq. ft.). Using an anionic polyacrylamide water-in-oil emulsion SUPERFLOC TM A-1883RS (Cytec Industries Incorporated, West Paterson, NJ, USA), and RHODAMEEN, an ethoxylated fatty amine cationic dispersant TM VP-532SPB (Rhodia Chemical Company, Cranbury, NJ, USA), disperses glass fibers in water. Hand sheets were formed in Williams (Williams Apparatus Company, Watertown, NY, USA) hand sheet molds. Transfer the wet hand sheet to a vacuum station for dehydration. The aqueous adhesive compositions described below were prepared, each applied to the dewatered sheets, and excess of the compositions removed in vacuo. The sheets were dried / cured in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com