Preparation method of ultramicro columnar K2Ti6O13 whiskers

A columnar and ultra-fine technology, applied in the field of inorganic fiber materials, can solve the problems of complex whisker processing, long holding time, environmental impact, etc., and achieve the effects of simple process, simple production equipment and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Heat and melt 30g of stearic acid at 80°C, after it is completely melted, press Ti(OC 2 h 5 ) 4 The / KOH molar ratio is 3:1.1. Add the initial material, that is, add 11ml of 1mol / L KOH aqueous solution while hot while stirring, and control the dropping rate at 30-45 drops / min. At the same time, add ethyl titanate 10.2 to the above system g, continue to stir for 40min, and obtain KOH-Ti(OC 2 h 5 ) 4 Gel; burn off most of the organic matter in the above gel in an electric furnace at 550°C to obtain K 2 Ti 6 o 13 Precursor. After cooling, ball mill for 30 minutes, then heat up to 900°C for 2 hours at a heating rate of 5°C / min, and then cool down with the furnace to obtain the ultrafine columnar K 2 Ti 6 o 13 whiskers.

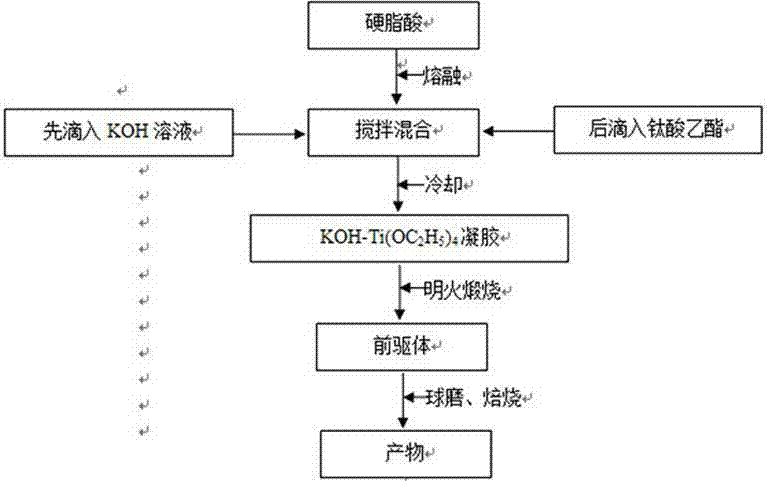

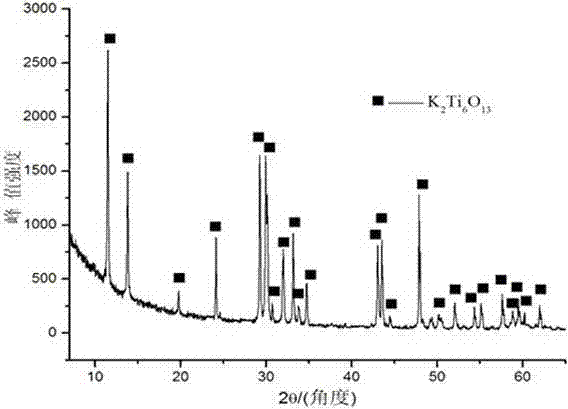

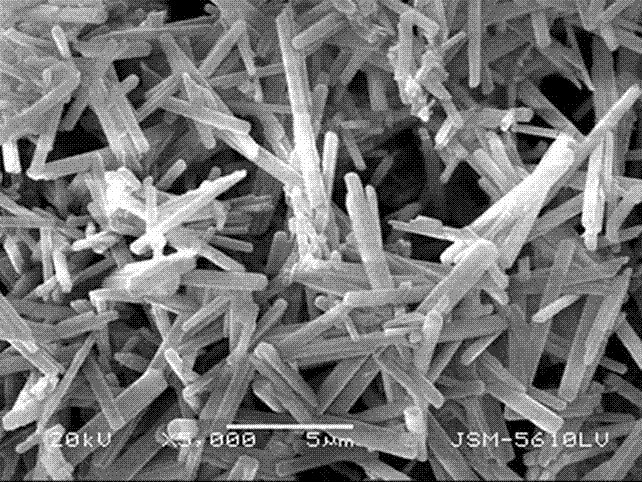

[0031] The ultrafine columnar K prepared in this embodiment 2 Ti 6 o 13 Whiskers, the process flow is as follows figure 1 , its XRD spectrum and field emission scanning electron photographs are shown in figure 2 , image 3 . Depend on f...

Embodiment 2

[0033] Heat and melt 35g of stearic acid at 90°C, after it is completely melted, press Ti(OC 2 h 5 ) 4 The / KOH molar ratio is 3:1.1. Add the initial material, that is, add 11ml of 1mol / L KOH aqueous solution while hot while stirring, and control the dropping rate at 30-45 drops / min. At the same time, add ethyl titanate 10.2 to the above system g, continue to stir for 60min, and obtain KOH-Ti(OC 2 h 5 ) 4 Gel; burn most of the organic matter in the above gel in an electric furnace at 600°C to obtain K 2 Ti 6 o 13 Precursor. After cooling, ball mill for 30 minutes, then heat up to 950°C at a heating rate of 7°C / min and calcined for 1.5 hours, and the ultrafine columnar K can be obtained after cooling in the furnace. 2 Ti 6 o 13 whiskers.

Embodiment 3

[0035] Heat and melt 32.5g stearic acid at 80°C, after it is completely melted, press Ti(OC 2 h 5 ) 4 The / KOH molar ratio is 3:1.1. Add the initial material, that is, add 11ml of 1mol / L KOH aqueous solution while hot while stirring, and control the dropping rate at 30-45 drops / min. At the same time, add ethyl titanate 10.2 to the above system g, continue to stir for 45min, and obtain KOH-Ti(OC 2 h 5 ) 4 Gel; burn most of the organic matter in the above gel in an electric furnace at 600°C to obtain K 2 Ti 6 o 13 Precursor. After cooling, ball mill for 30 min, then heat up to 850 °C for 3 hours at a heating rate of 6 °C / min to obtain the ultrafine columnar K 2 Ti 6 o 13 whiskers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com