Curable resin composition for photo spacer, column spacer and liquid crystal display

A curable resin and photosensitive spacer technology, which is applied in the field of curable resin composition and column spacer, can solve the problems of lack of elastic recovery force, inability to maintain the distance between substrates, and insufficient recovery, etc., and achieve good substrate adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0133]35 parts of benzylmaleimide (BzMI), 114 parts of acrylic acid (AA), 42 parts of acryloylmorpholine (ACMO; manufactured by Kojinsha), ethoxylated o-phenylphenol acrylate (trade name "A -LEN-10"; manufactured by Shin-Nakamura Chemical Co., Ltd.), 42 parts, tert-butyl peroxy-2-ethylhexanoate ("パググチル (registered trademark) O", manufactured by NOF Corporation; (PBO)) 4.7 parts , 56 parts of propylene glycol methyl ether acetate (PGMEA) and 84 parts of propylene glycol monomethyl ether (PGME) were fully stirred and mixed into the monomer dropping tank. In addition, 2.8 parts of n-dodecyl mercaptan (n-DM), 12 parts of polysiloxane modified with mercapto groups at both ends (trade name "X-22-167B"; manufactured by Shin-Etsu Silicone Co., Ltd.), and 19 parts of PGMEA And 29 parts of PGME are fully stirred and mixed into the chain transfer agent dropping tank.

[0134] A detachable flask with a cooling tube was prepared as a reaction tank, and 142 parts of PGMEA and 214 parts of ...

Embodiment 1-2

[0137] [Synthesis of Monomer]

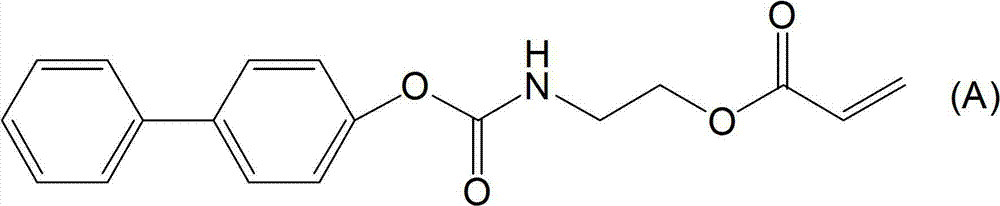

[0138] In a container equipped with a stirring device, a thermometer, a reflux cooler, a nitrogen introduction pipe, and a dropping funnel, add 200 parts of tetrahydrofuran as a solvent, 106 parts of p-hydroxybiphenyl, 1 part of dibutyltin dilaurate as a catalyst, and 0.1 part of 2,6-dibutyl-4-methylphenol as a polymerization inhibitor is dripped from the dropping funnel at 40°C for 1 hour while blowing nitrogen / oxygen mixed gas (oxygen concentration 7% by volume) After adding 88 parts of 2-isocyanate ethyl acrylate (trade name "Karenz AOI (registered trademark)", manufactured by Showa Denko Co., Ltd.), the mixture was reacted at 60° C. for 2 hours. Then, the synthesized compound (A) as a biphenyl group-containing monomer was precipitated using a weak solvent, n-hexane, to obtain a compound (A).

[0139] [Synthesis of Polymer]

[0140] 35 parts of BzMI, 114 parts of AA, 84 parts of the above-mentioned compound (A), 4.7 parts of PBO, 98 parts o...

Embodiment 1-3

[0144] 38 parts of BzMI, 124 parts of AA, 91 parts of A-LEN-10, 5.1 parts of PBO, 106 parts of PGMEA, and 46 parts of PGME were fully stirred and mixed into the monomer dropping tank. Moreover, the mixture which fully stirred and mixed 3.8 parts of n-DM, 47 parts of PGMEA, and 20 parts of PGME was put into the chain transfer agent dripping tank.

[0145] A detachable flask with a cooling tube was prepared as a reaction tank, and 414 parts of PGMEA and 177 parts of PGME were added to the reaction tank. After nitrogen replacement, the reaction tank was heated by an oil bath while stirring, and the temperature of the reaction tank was raised to 90°C. After the temperature of the reaction tank was stabilized at 90° C., each component was dropped from the monomer dropping tank and the chain transfer agent dropping tank. While maintaining the inner temperature of the flask at 90° C., each dropping was performed for 180 minutes each. After the completion of the dropwise addition, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com