Method for improving surface passivation of solar cell

A solar cell and tubular technology, which is applied in the direction of circuits, electrical components, sustainable manufacturing/processing, etc., can solve the problems of low production efficiency and high cost, improve the lifetime of minority carriers, and the method is simple and easy to operate, reducing dangling bonds and crystals The effect of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

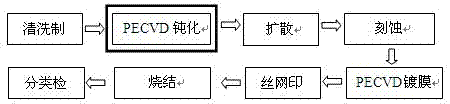

[0011] A method for improving the surface passivation of solar cells provided by the present invention will be further described in the following specific embodiments. This embodiment is carried out under the same conditions as the original process in the processes of texturing, diffusion, etching, PECVD, and screen printing. The specific implementation is as follows:

[0012] (1) Place the cleaned and textured polysilicon wafer in a graphite boat and put it into a tubular PECVD device for hydrogen ion passivation.

[0013] (2) During the passivation process, tubular PECVD does not need to feed silane, and only ammonia gas is fed under the action of plasma. The passivation parameters are power 5000W, temperature 450°C, pressure 1700 mTorr, ammonia gas flow rate 7slm, accounting for The empty ratio is 5:50, and the processing time is 15 minutes.

[0014] (3) The hydrogen-passivated silicon wafers are sequentially diffused, etched, PECVD, screen-printed, sintered, and sorted t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com