Application of organic framework porous solid acid

A porous solid and organic framework technology, applied in the preparation of organic compounds, organic chemistry, organic compound/hydride/coordination complex catalysts, etc., can solve the problems of lack of pore structure, low specific surface area, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] First, tetrahydrofuran and water are used as a mixed solvent to synthesize the mesoporous polydivinylbenzene material, which is PDVB.

[0020] Add 2g of DVB monomer to a mixed solvent containing 0.03-0.05g of azobisisobutyronitrile, 10-20ml of tetrahydrofuran, 1-2ml of water, and stir at room temperature and pressure for more than 3 hours, then 75-150°C water After heat treatment for 1-2 days, take it out, open the lid, and evaporate the dry solvent at room temperature to obtain a polydivinylbenzene material (PDVB) with high specific surface area and rich mesoporous structure.

Embodiment 2

[0022] Choose dichloromethane as the solvent and concentrated sulfuric acid as the sulfonation reagent for the sulfonation reaction.

[0023] (1) Grind 2-3g PDVB into ultrafine powder, and degas it under nitrogen at 100-150℃ for 10h;

[0024] (2) Swelling process: Adding 2.0 g of PDVB block to an excessive amount of solvent, the PDVB material quickly swells, and the PDVB quickly bursts into small pieces, accompanied by rapid volume expansion.

[0025] (3) Take 30mL of dichloromethane and 70mL of concentrated sulfuric acid and mix well, add 0.2g of silver sulfate as a catalyst. After stirring evenly, add the above PDVB, stir vigorously, and raise the temperature to 90℃ for 12h to complete the reaction and filter the product. Wash with dioxane, wash with water to neutral, dry at 80°C, activate with 0.1M sulfuric acid for 4 hours, wash with plenty of water to neutral, dry, and set aside.

Embodiment 3

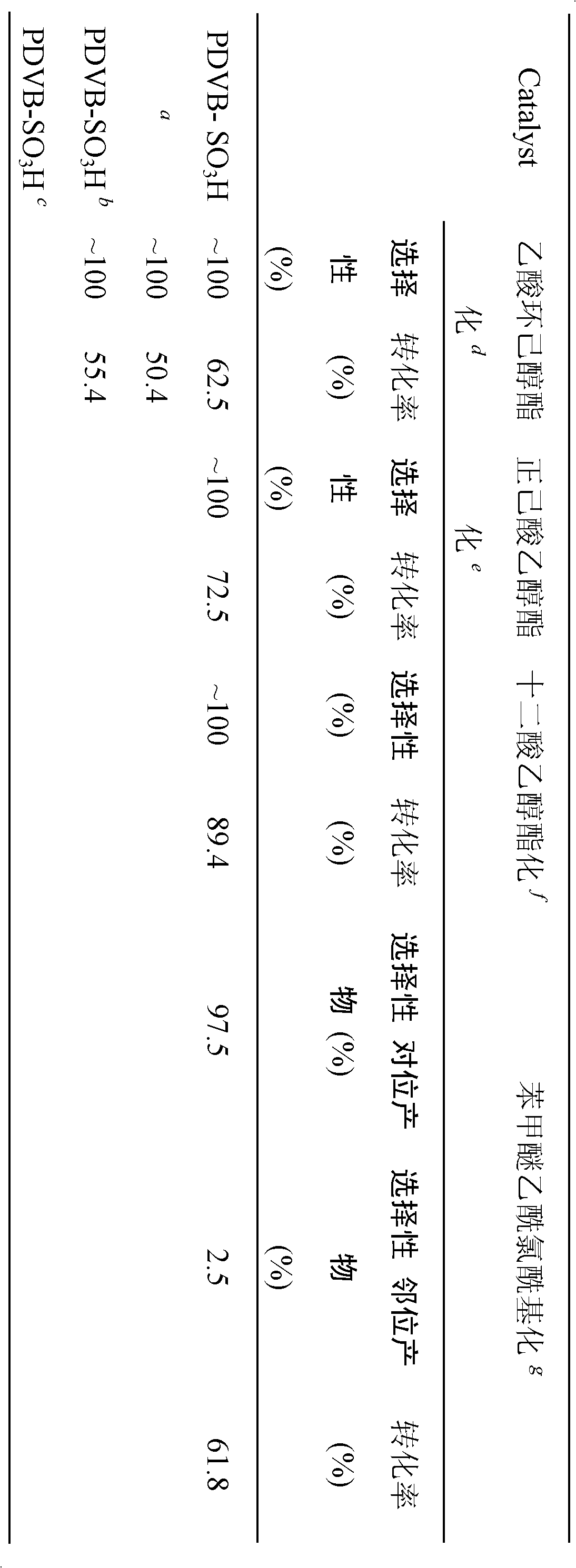

[0027] Catalytic performance evaluation and its comparison with traditional catalytic materials

[0028] Esterification reaction conditions of acetic acid and cyclohexanol: 0.2g catalyst, 11.5mL cyclohexanol, 17.5mL glacial acetic acid were mixed uniformly, and the reaction was completed at 100°C for 5 hours, dodecane was used as the internal standard.

[0029] Esterification reaction conditions of n-hexanoic acid and ethanol: 0.3g catalyst, 6.26mL n-hexanoic acid, 11.67mL ethanol are mixed uniformly, and the reaction is completed at 80°C for 5h, dodecane is the internal standard.

[0030] The esterification reaction conditions of dodecanoic acid and ethanol: 0.15g catalyst, 4mmol dodecanoic acid, and 50mmol ethanol were mixed uniformly and the reaction was completed at 70°C for 5h, and dodecane was used as the internal standard.

[0031] Fuchs acylation reaction: 0.3g catalyst, 5.5mL anisole, 0.71mL acetyl chloride are mixed uniformly, and the reaction is completed at 60°C for 5h, dod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com