Nano porous fixed acid catalyst with organic frame and synthesis method thereof

An organic framework, nanoporous technology, applied in the field of material chemistry, can solve the problems of poor stability and low specific surface area, and achieve the effects of improved stability, large specific surface area, and improved cross-linking degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] First, tetrahydrofuran and water are used as a mixed solvent to synthesize the mesoporous polydivinylbenzene material, which is PDVB.

[0032] Add 2g DVB monomer to a mixed solvent of 0.03-0.05g azobisisobutyronitrile, 10-20ml tetrahydrofuran, 1-2ml water, stir under normal temperature and pressure for more than 3 hours, then 75-150°C water After heat treatment for 1-2 days, take it out, open the lid, and evaporate the dry solvent at room temperature to obtain a polydivinylbenzene material (PDVB) with high specific surface area and rich mesoporous structure.

Embodiment 2

[0034] Choose dichloromethane / toluene / carbon tetrachloride as the solvent, and concentrated sulfuric acid as the sulfonation reagent for the sulfonation reaction.

[0035] Grind 2-3g PDVB into ultra-fine powder and degas it for 10h under nitrogen at 100-150℃; swelling process: Add 2.0g PDVB block to excess solvent, PDVB material swells quickly, PDVB bursts into small pieces quickly , And accompanied by rapid expansion of volume.

[0036] Take 30mL of chloroform and 70mL of fuming sulfuric acid, stir evenly, add the above PDVB, stir vigorously, increase the temperature to room temperature for sulfonation for 24h, end the reaction, filter the product, wash with dioxane, and wash to neutral, 80℃ Dry, wash with 0.1M sulfuric acid and activate for 4 hours, then wash with plenty of water until it is neutral, dry, and set aside.

Embodiment 3

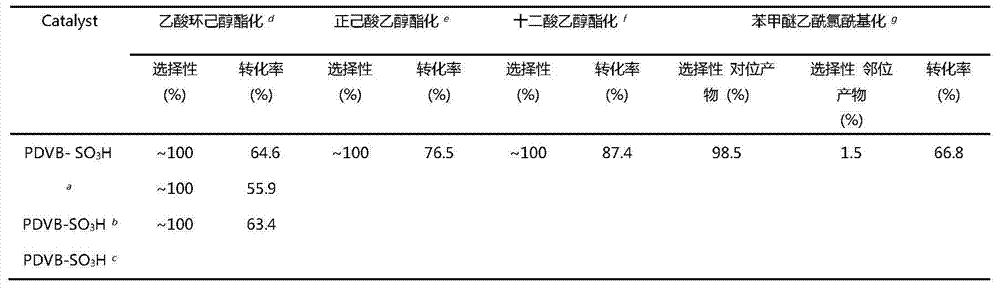

[0038] Catalytic performance evaluation and its comparison with traditional catalytic materials

[0039] Esterification reaction conditions of acetic acid and cyclohexanol: 0.2g catalyst, 11.5mL cyclohexanol, 17.5mL glacial acetic acid were mixed uniformly, and the reaction was completed at 100°C for 5 hours, dodecane was used as the internal standard.

[0040] Esterification reaction conditions of n-hexanoic acid and ethanol: 0.3g catalyst, 6.26mL n-hexanoic acid, 11.67mL ethanol are mixed uniformly, and the reaction is completed at 80°C for 5h, dodecane is the internal standard.

[0041] The esterification reaction conditions of dodecanoic acid and ethanol: 0.15g catalyst, 4mmol dodecanoic acid, and 50mmol ethanol were mixed uniformly and the reaction was completed at 70°C for 5h, and dodecane was used as the internal standard.

[0042] Fuchs acylation reaction: 0.3g catalyst, 5.5mL anisole, 0.71mL acetyl chloride are mixed uniformly, and the reaction is completed at 60°C for 5h, dod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com