Modified catalyst for preparing methyl mercaptan containing sulfur-containing synthesis gas and preparation method thereof

A technology for synthesis gas and methyl mercaptan, which is used in the preparation of mercaptans, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Weigh 1.50g ammonium molybdate tetrahydrate, 0.95g potassium hydroxide and 0.49g nickel nitrate hexahydrate, add 10ml deionized water to dissolve and configure become Impregnation solution, impregnated on 6g of silica gel carrier to just submerge the carrier, after aging for 8 hours, dry at 100°C for 6~8 hours to obtain the modified pre-catalyst, denoted as Mo-O-K / Ni / SiO 2 ;

[0016] Then in Mo-O-K / Ni / SiO 2 Add 30ml of ethanol aqueous solution, the ethanol aqueous solution is prepared by water and ethanol with a volume ratio of 1:1; then add 2.4ml of MTES drop by drop under stirring, then continue to stir at room temperature for 3h, and then reflux to stir the reaction 2.5h, cooled to room temperature, washed with ethanol and suction filtered, and dried at 100°C to obtain a mass ratio of molybdenum source to carrier of 0.25:1, and a molar ratio of potassium source K to molybdenum source Mo of 2:1; activity The molar ratio of the accelerator Ni to the molybdenum source...

Embodiment 2

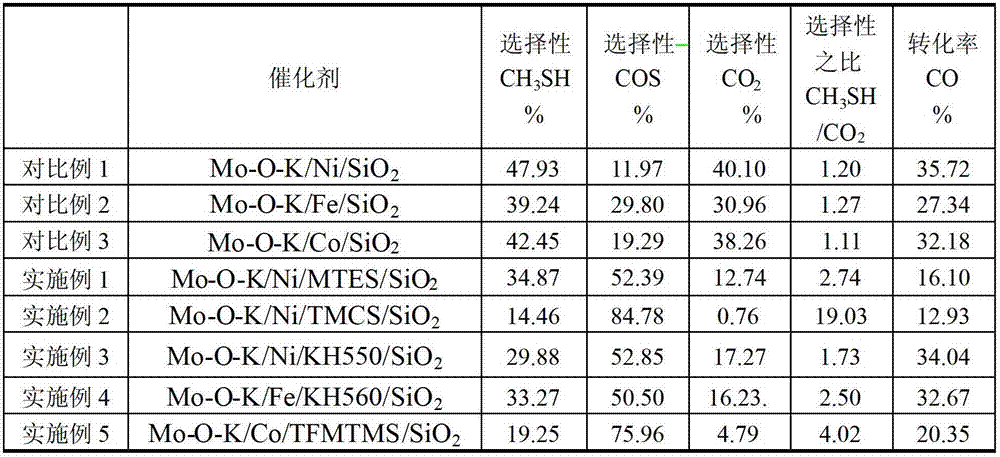

[0020] Change the volume ratio of water to ethanol in the ethanol aqueous solution used in the preparation method of Example 1 to 0.5:1, change the coupling agent to 3.6ml of TMCS, and other conditions are the same as in Example 1. Finally, the mass ratio of the molybdenum source and the carrier is 0.25:1, the molar ratio of the potassium source K and the molybdenum source Mo is 2:1; the molar ratio of the activity promoter Ni and the molybdenum source Mo is 0.2:1; The modified catalyst Mo-O-K / Ni / TMCS / SiO added in an amount of 0.6ml per gram of carrier 2 , The catalyst activity evaluation results are listed in Table 1 below.

Embodiment 3

[0022]Change the volume ratio of water to ethanol in the aqueous ethanol solution used in the preparation method of Example 1 to 0.:1, change the coupling agent to 4.8ml of KH550, and other conditions are the same as in Example 1. Finally, the mass ratio of the molybdenum source to the carrier is 0.25:1, the molar ratio of the potassium source K to the molybdenum source Mo is 2:1; the molar ratio of the activity accelerator Ni to the molybdenum source Mo is 0.2:1; The modified catalyst Mo-O-K / Ni / KH550 / SiO added in an amount of 0.8ml per gram of carrier 2 , The catalyst activity evaluation results are listed in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com