Preparation method of high dielectric constant gate dielectric lanthanum titanium oxide amorphous film

An amorphous film and gate dielectric technology, applied in the field of functional ceramics, can solve the problems of high leakage current density of lanthanum titanium oxide amorphous film, and achieve the effect of high dielectric constant and low leakage current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

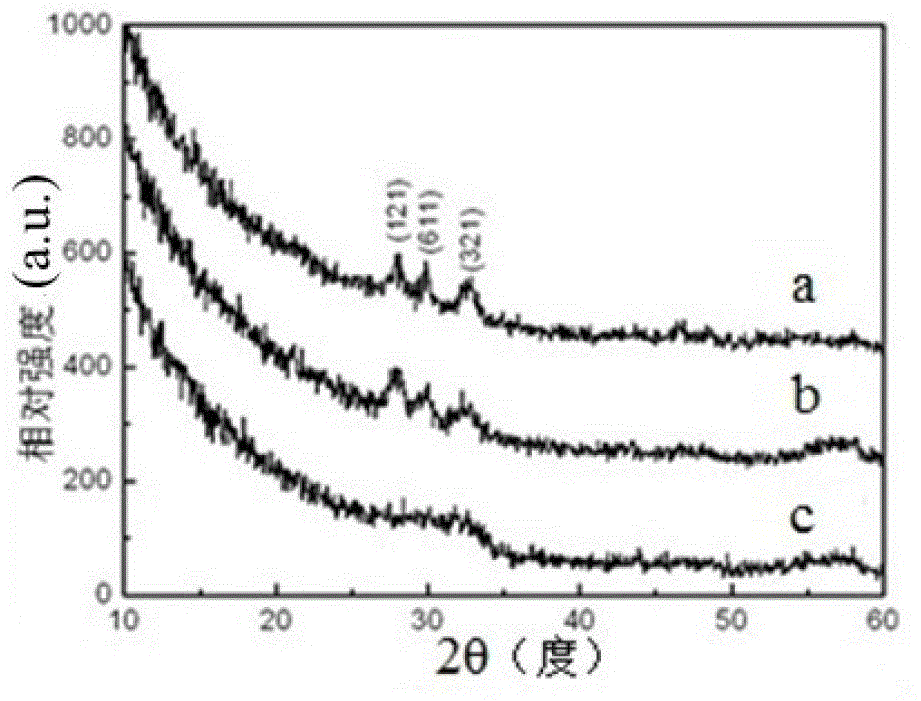

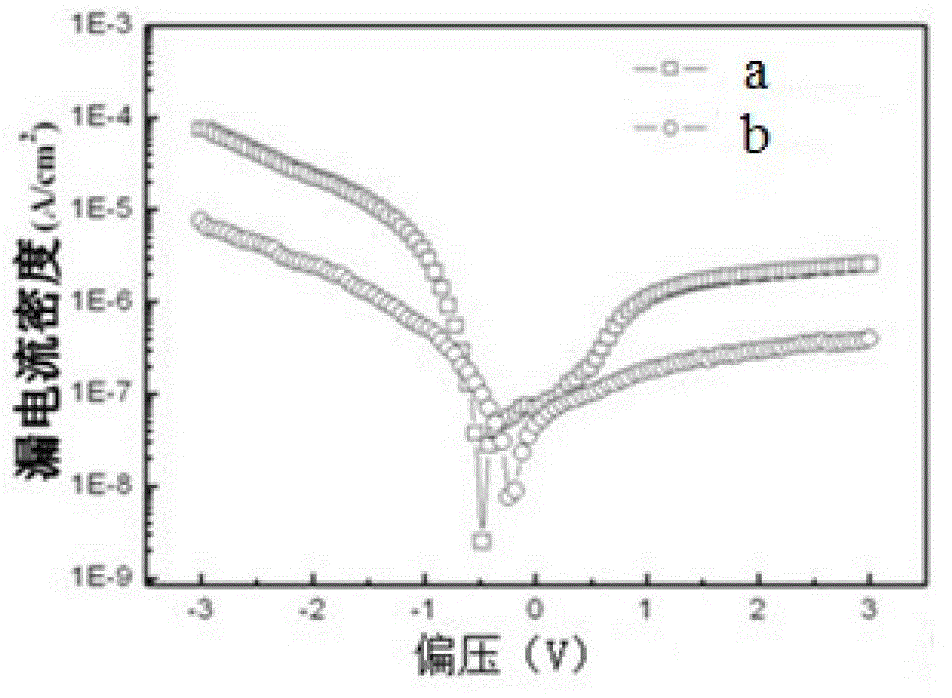

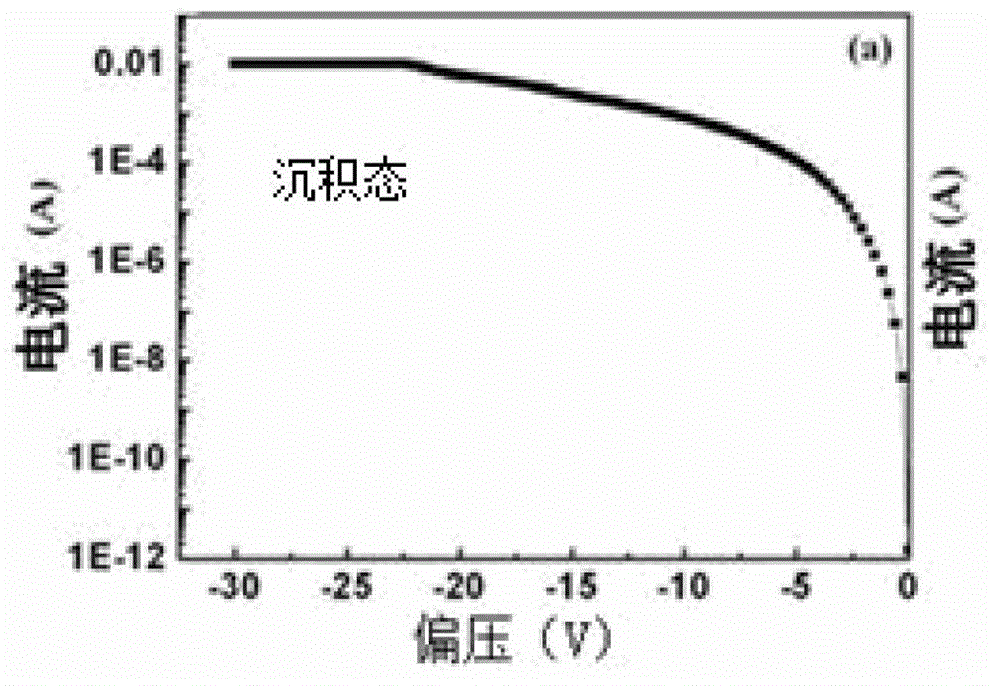

[0020] Embodiment 1, weighing purity is 99.99% LaTiO 3.5 particles as film material, LaTiO 3.5 The particle size is 2-3mm. A p-type Si (100) with a diameter of 75mm is used as a substrate, its resistivity is 2-10Ω·cm, and its thickness is 0.5mm. After the substrate is thoroughly cleaned, it is quickly placed in a vacuum chamber, and the substrate is heated with a heating system to keep its temperature at 100°C. The background vacuum before evaporation is less than 3×10 -3 Pa, during the evaporation process, in order to obtain a higher oxygen content, use O with a purity of 99.99% 2 as a reactive gas. The evaporation time was 6 minutes, and the beam current of the electron gun was 70mA to obtain a lanthanum titanyl oxide amorphous film in a deposited state. The as-deposited film was rapidly annealed at 700°C for 5 minutes to obtain an amorphous film of lanthanum titanyl oxide.

[0021] The phase structure of the film was analyzed by XRD; the composition of the film was an...

Embodiment 2

[0022] Embodiment 2, weighing purity is 99.99% LaTiO 3.5 particles as film material, LaTiO 3.5 The particle size is 2-3mm. A p-type Si (100) with a diameter of 75mm is used as a substrate, its resistivity is 2-10Ω·cm, and its thickness is 0.5mm. After the substrate is thoroughly cleaned, it is quickly placed in a vacuum chamber, and the substrate is heated with a heating system to keep its temperature at 150°C. The background vacuum before evaporation is less than 3×10 -3 Pa, during the evaporation process, in order to obtain a higher oxygen content, use O with a purity of 99.99% 2 as a reactive gas. The evaporation time was 4 minutes, and the beam current of the electron gun was 80mA to obtain a lanthanum titanyl oxide amorphous film in a deposited state. The as-deposited film was rapidly annealed at 750°C for 4 minutes to obtain an amorphous film of lanthanum titanyl oxide.

[0023] The phase structure and morphology of the film were analyzed by XRD and SEM; the compos...

Embodiment 3

[0024] Embodiment 3, weighing purity is 99.99% LaTiO 3.5 particles as film material, LaTiO 3.5 The particle size is 2-3mm. A p-type Si (100) with a diameter of 75mm is used as a substrate, its resistivity is 2-10Ω·cm, and its thickness is 0.5mm. After the substrate is thoroughly cleaned, it is quickly placed in a vacuum chamber, and the substrate is heated with a heating system to keep its temperature at 200°C. The background vacuum before evaporation is less than 3×10 -3 Pa, during the evaporation process, in order to obtain a higher oxygen content, use O with a purity of 99.99% 2 as a reactive gas. The evaporation time was 2 min, and the beam current of the electron gun was 85 mA to obtain a deposited amorphous lanthanum titanyl film. The as-deposited film was rapidly annealed at 800°C for 2 minutes to obtain an amorphous film of lanthanum titanyl oxide.

[0025] The phase structure and morphology of the film were analyzed by XRD and SEM; the composition of the film wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Leakage current density | aaaaa | aaaaa |

| Leakage current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com