Insulating material forming composition for electronic elements, insulating material for electronic elements, electronic element, and thin film transistor

A technology for electronic components and insulating materials, which is applied in the field of compositions for forming insulating materials for electronic components, can solve the problems of inability to form components, high leakage current density, and inability to withstand the coating process, and achieve low leakage current density and low leakage The effect of current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0269] 0.4 g (colorless transparent liquid) of 1,3-adamantane dimethanol diacrylate (compound (1)) (manufactured by Idemitsu Kosan Co., Ltd.) represented by the following structural formula, benzoin as a polymerization initiator 0.04 g of isobutyl ether and 4 g of MEK as a solvent were mixed to obtain a composition for forming an insulating material (film) having a solid content concentration of 10% by mass.

[0270] [chemical formula 28]

[0271]

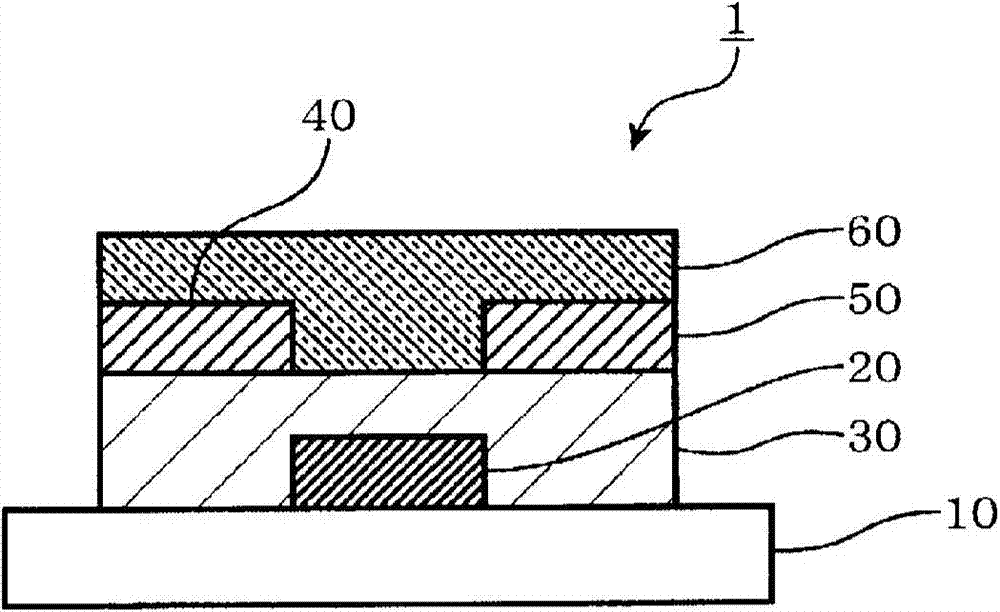

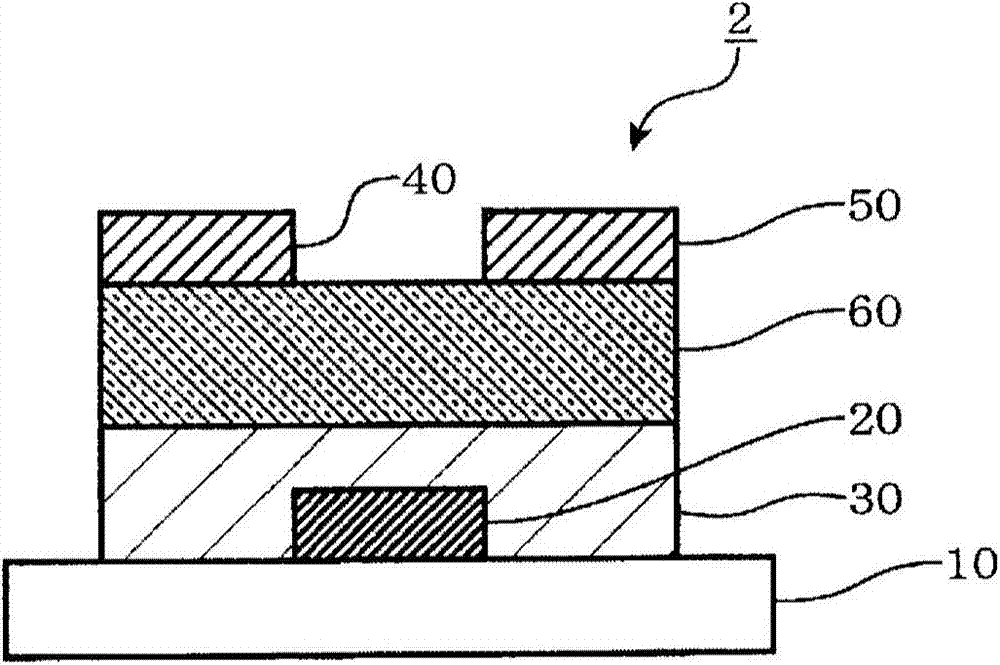

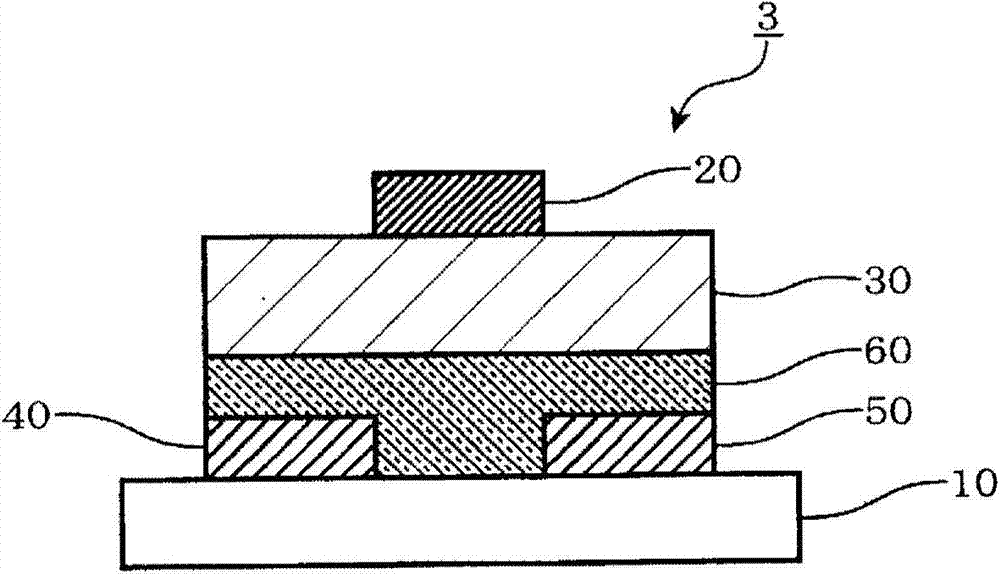

[0272] Use glass with a size of 25 × 20 × 1.1mm as a substrate, form an ITO film with a thickness of 100 nm on the substrate, and use photolithography to pattern it to make a transparent gate electrode (hereinafter, the substrate with the ITO film is referred to as transparent. supporting substrate). Clean the transparent support substrate with isopropanol ultrasonically for 5 minutes, then clean it with pure water for 5 minutes, then use isopropanol ultrasonically for 5 minutes, then blow dry it. 2 air to dry. Then, finally,...

Embodiment 2

[0291] Using a composition containing the following compound (2) instead of compound (1), the same operation as in Example 1 was performed to form an insulator layer, and the same operation as in Example 1 was performed to evaluate the insulator layer. Compound (2) was produced by the method described in Examples 1 and 2 of WO2007 / 020901 pamphlet. The results are shown in Table 1. Then, the same operation as in Example 1 was performed to fabricate a thin film transistor and evaluate it. The results are shown in Table 2.

[0292] [chemical formula 29]

[0293]

Embodiment 3

[0295] Using a composition containing the following compound (3) (agent manufactured by Aldrich Corporation) instead of compound (1), the same operation as in Example 1 was used to form an insulator layer, and the same operation as in Example 1 was performed for the insulator layer. evaluate. The results are shown in Table 1.

[0296] [chemical formula 30]

[0297]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com