Color coated steel plate with vibration and noise reduction functions and method for manufacturing color coated steel plate

A technology of vibration reduction and noise reduction, color coating, applied in coating, chemical instruments and methods, lamination and other directions, can solve the problems of expensive, heavy steel plate, unseen steel plate, etc., to reduce vibration, reduce amplitude, The effect of concise process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

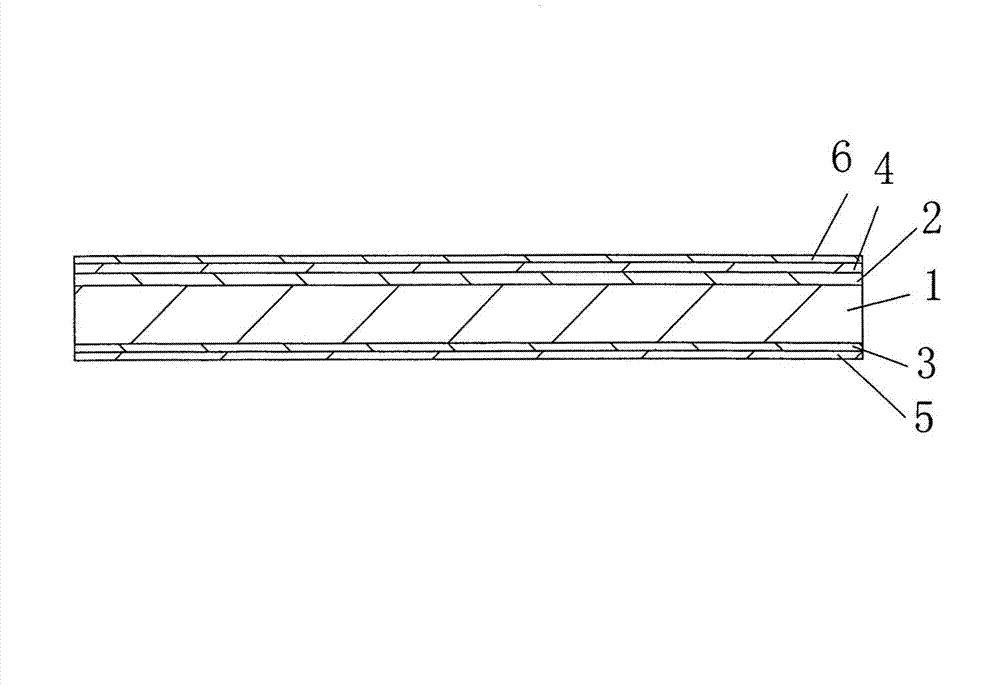

[0028] prepared by figure 1 The color-coated steel plate with vibration and noise reduction functions of the structure shown.

[0029] A) Uncoiling and pretreatment, uncoiling the colored galvanized steel sheet with a thickness of 1.2 mm and in the shape of a roll, and cleaning the surfaces on both sides after uncoiling. The cleaning method is preferably disk brush cleaning, and after the disk brush cleaning Alkaline cleaning and electrolytic cleaning, or pickling and electrolytic cleaning after dish brushing, or electrolytic cleaning directly after dish brushing, in order to remove surface oxide skin and / or oil stains, etc. Drying in the drying tunnel, the drying temperature is 90°C, the traveling speed of the steel plate is 60m / min, and the color coated steel plate substrate 1 is obtained;

[0030] B) Passivation treatment, preferably using a roller coating method to apply a trivalent chromium solution with a mass concentration of 30g / L at room temperature on one sid...

Embodiment 2

[0035] A) Uncoiling and pretreatment, uncoiling the color galvalume steel plate with a thickness of 0.2 mm and in the shape of a roll, cleaning the surfaces on both sides after uncoiling, and guiding the color galvanized steel plate through the drying tunnel after cleaning Drying, the drying temperature is 70°C, the traveling speed of the steel plate is 70m / min, and the color coated steel plate substrate 1 is obtained;

[0036] B) Passivation treatment, preferably using a roller coating method to apply a trivalent chromium solution with a mass concentration of 15g / L at room temperature on one side surface and the other side of the color-coated steel plate substrate 1 obtained in step A). surface, so that the first conversion layer 2 is formed on the one side surface, and the second conversion layer 3 is formed on the other side surface. In this embodiment, the first and second conversion layers 2, 3 are blunt The thickness of the chemical film layer is 1 μm, and the steel ...

Embodiment 3

[0041] A) Uncoiling and pretreatment, uncoiling the colored galvanized steel sheet with a thickness of 0.7 mm and in the shape of a roll, cleaning the surfaces on both sides after uncoiling, and guiding the colored galvanized steel sheet through the drying tunnel to dry after cleaning. The drying temperature is 80° C., the traveling speed of the steel plate is 65 m / min, and the color coated steel plate substrate 1 is obtained;

[0042] B) Passivation treatment, preferably using a roller coating method to apply a trivalent chromium solution with a mass concentration of 22g / L at room temperature on one side surface and the other side of the color-coated steel plate substrate 1 obtained in step A). surface, so that the first conversion layer 2 is formed on the one side surface, and the second conversion layer 3 is formed on the other side surface. In this embodiment, the first and second conversion layers 2, 3 are blunt The thickness of the chemical film layer is 2 μm, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com