Foam glass and production method thereof

A foam glass and production method technology, applied in the field of industrial production, can solve the problems of insufficient thermal conductivity of foam glass, insufficient strength of foam glass, influence on the overall performance of finished products, etc., and achieve dense distribution, small expansion coefficient, and good fluidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

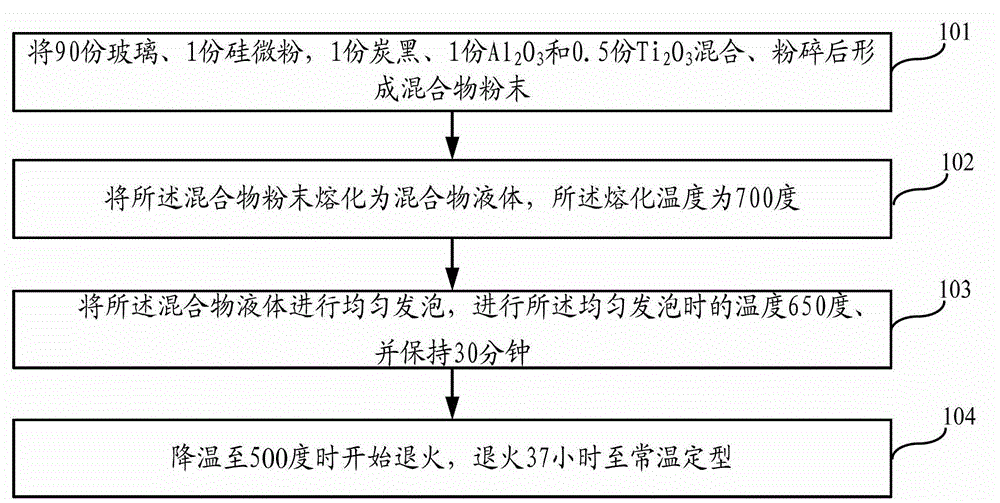

[0037] Embodiment 1: as figure 1 shown

[0038] 101. Mix 90 parts of glass, 1 part of silicon powder, 1 part of carbon black, and 1 part of Al 2 o 3 and 0.5 parts Ti 2 o 3 After mixing and pulverizing, a mixture powder is formed;

[0039] 102. Melting the mixture powder into a mixture liquid, the melting temperature is 700 degrees;

[0040] 103. Foaming the liquid mixture uniformly, the temperature during the uniform foaming is 650 degrees, and keep it for 30 minutes;

[0041] 104. Start annealing when the temperature is lowered to 500 degrees, and anneal for 37 hours to room temperature for setting.

Embodiment 2

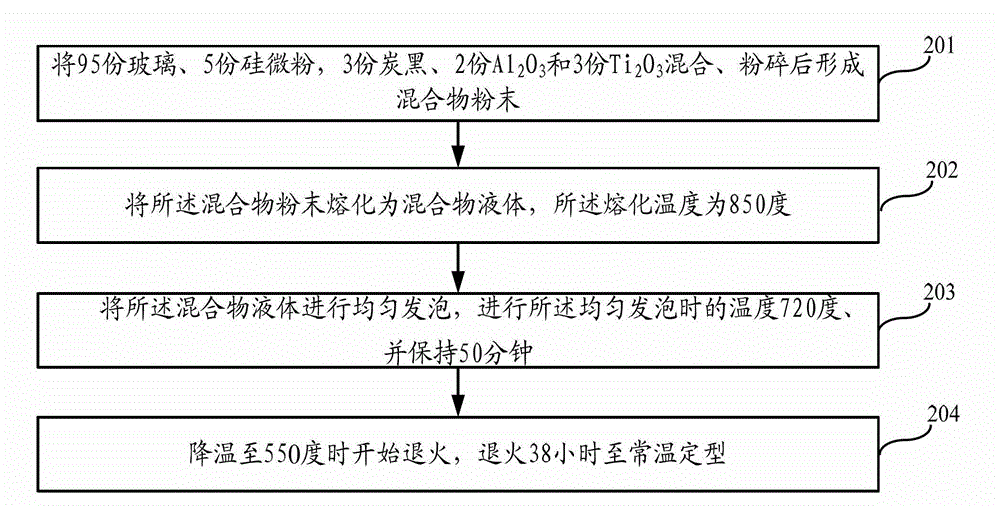

[0042] Embodiment 2: as figure 2 shown

[0043] 201. 95 parts of glass, 5 parts of silicon powder, 3 parts of carbon black, 2 parts of Al 2 o 3 and 3 Ti 2 o 3 After mixing and pulverizing, a mixture powder is formed;

[0044] 202. Melting the mixture powder into a mixture liquid, the melting temperature is 850 degrees;

[0045] 203. Foaming the mixture liquid uniformly, the temperature of the uniform foaming is 720 degrees, and keeping it for 50 minutes;

[0046] 204. Start annealing when the temperature drops to 550 degrees, and anneal for 38 hours to room temperature for setting.

Embodiment 3

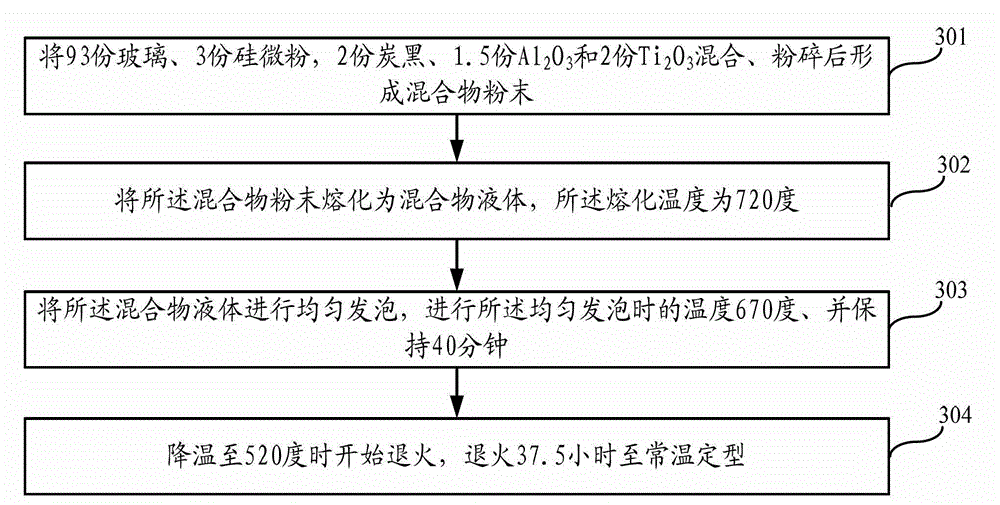

[0047] Embodiment 3: as image 3 shown

[0048] 301. 93 parts of glass, 3 parts of silicon powder, 2 parts of carbon black, 1.5 parts of Al 2 o 3 and 2 Ti 2 o 3 After mixing and pulverizing, a mixture powder is formed;

[0049] 302. Melting the mixture powder into a mixture liquid, the melting temperature is 720 degrees;

[0050] 303. Foaming the liquid mixture uniformly, the temperature during the uniform foaming is 670 degrees, and keeping it for 40 minutes;

[0051] 304. Start annealing when the temperature drops to 520 degrees, and anneal for 37.5 hours to room temperature for setting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com