Fabric for protective clothing, and spun yarn for same

A fabric and spinning technology, applied in the spinning field, can solve problems such as wearing comfort, and achieve good dyeability, less carbonization, and good wearing feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] 1. Fiber used

[0071] (1) Polyetherimide fiber

[0072] The polyetherimide fiber is "ULTEM" manufactured by SABIC INNOVATIVE PLASTICS (limiting oxygen index (LOI) is 32), the single fiber fineness is 3.3 deci tex (3 denier), and the average fiber length is 89mm. Raw cotton is dyed olive green color. As a dyeing machine, a high-pressure dyeing machine manufactured by Nissen Corporation was used, and as dyes and other additives, KAYARON POLYESTER YELLOW FSL (Nippon Kayaku) 3.60% o.w.f., KAYARON RED SSL (Nippon Kayaku) 0.36% o.w.f., and KAYARON POLYESTER BLUE SSL were added (Nippon Kayaku) 1.24% o.w.f., acetic acid (68wt%) 0.0036% o.w.f., sodium acetate 0.0067% o.w.f., dyed at 135°C for 60 minutes.

[0073] (2) wool fiber

[0074] Non-modified wool (average fiber length: 75 mm) of Australian Merino sheep was used as the wool fiber, and it was dyed olive green by a conventional method using an acid dye.

[0075] (3) Para-aramid fiber

[0076] The Teijin Co., Ltd. prod...

Embodiment 2

[0091] In Example 2, it carried out similarly to Example 1 except having made the compounding quantity of the fiber into Table 5.

[0092] table 5

[0093]

[0094] (Remarks 1) The * of the experiment No. indicates a comparative example.

[0095] (Note 2) PEI is the abbreviation of polyetherimide.

[0096] From Table 5, it was confirmed that the fabrics of Examples of the present invention have no thermal shrinkage, have a carbonization length of 10 cm or less, have high heat resistance and flame retardancy, and have good dyeability (appearance).

[0097] On the other hand, the comparative example had the following problems.

[0098] (1) Experiment No. 2-1 was not preferable because it had only polyetherimide fibers and wool, and therefore thermal shrinkage occurred and the carbonization length was long.

[0099] (2) In Experiment No. 2-2, the amount of para-aramid fibers was too small, and thermal shrinkage occurred, which is not preferable.

[0100] (3) From Experimen...

Embodiment 3

[0107] Use 39.5% by mass of flame-retardant rayon, that is, the trade name "Viscose FR" of Austrian Lenzing Company (average fiber length is 75mm, average fineness is 3.3 deci tex) to replace the wool of Example 1, and the spun dyed fabric of Example 1 Raw cotton with 50% by mass of polyetherimide fiber, 10% by mass of para-aramid fiber (pre-spun dyed product) and 0.5% by mass of antistatic fiber was respectively put into the worsted carding machine for fiber opening. Blending is carried out by sliver mixing after the fiber web is formed, and the spinning of double filaments (2 / 44) with a metric count of 44 is made as a warp yarn after the pre-spinning process and the spinning process. Warp and weft are the same product. Table 6 shows the twist direction, twist number, twist coefficient, and yarn count of each yarn.

[0108] Table 6

[0109]

Uniform blend spinning (monofilament)

Uniform blend spinning (double filament)

twist direction

Z

S ...

PUM

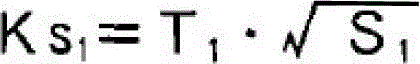

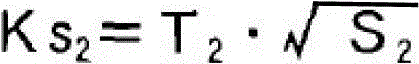

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com