Manganese-base catalyst for synthesizing alpha-tetralone from tetrahydronaphthalene and preparation method thereof

A technology of manganese-based catalyst and tetralone, which is applied in the field of manganese-based catalyst and its preparation, can solve the problems of difficulty in recycling, high reaction temperature, and high catalyst toxicity of α-tetralone, and achieve low temperature, high The effect of high catalytic activity and good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

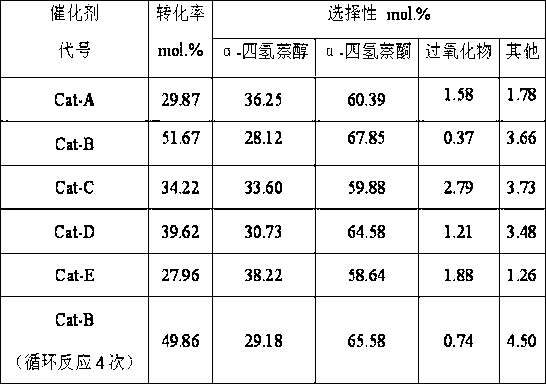

Embodiment 1

[0014] Embodiment 1: with 0.2396 grams of Mn (NO 3 ) 2 4H 2 O and 0.0581 g of Zr(NO 3 ) 4 ·5H 2 Immerse 1 gram of activated alumina with a particle size of 0.10 mm in an equal volume at room temperature for 24 h in an aqueous solution prepared with O, dry at 60 °C for 4 h in an air atmosphere, and then roast at 400 °C for 6 h to obtain zirconium-modified manganese The base catalyst is recorded as Cat-A, and its composition is shown in Table 1.

Embodiment 2

[0015] Embodiment 2: with 0.4468 gram of Mn (NO 3 ) 2 4H 2 O and 0.1734 g Co(NO 3 ) 2 ·6H 2 O impregnate 1 gram of activated alumina with a particle size of 0.15 mm in an equal volume at room temperature for 36 h in the prepared aqueous solution. After impregnation, dry at 80 °C for 4 h and roast at 550 °C for 4 h in an air atmosphere to obtain cobalt-modified manganese The base catalyst is recorded as Cat-B, and its composition is shown in Table 1.

Embodiment 3

[0016] Embodiment 3: with 0.5991 gram of Mn (NO 3 ) 2 4H 2 O and 0.2109 g Fe(NO 3 ) 3 9H 2 The aqueous solution prepared by O was impregnated with an equal volume of 1 gram of activated alumina with a particle size of 0.50 mm for 24 h at room temperature. After the impregnation was completed, it was dried at 100 °C for 3 h and calcined at 600 °C for 3 h in an air atmosphere to obtain iron-modified manganese-based The catalyst is recorded as Cat-C, and its composition is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com