Method for synthesizing tricalcium silicate single mineral from polyvinyl alcohol solution

A technology of polyvinyl alcohol solution and single mineral, applied in the direction of silicate, alkaline earth metal silicate, etc., can solve the problems of uneven mixing of reactants, difficulty in ion diffusion, long time, etc., to prevent aggregation and crystallization behavior , High product purity, simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

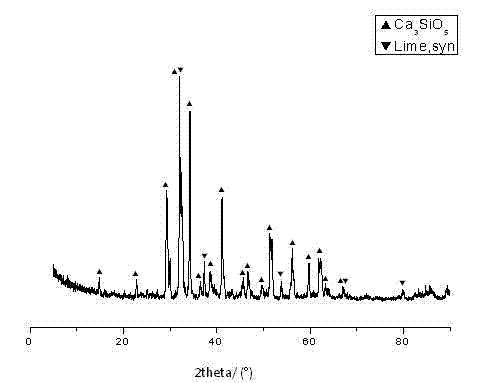

Embodiment 1

[0029] Embodiment 1, a kind of synthetic tricalcium silicate (C 3 S) the method of single mineral, its raw material weight ratio is: Ca(NO 3 ) 2 4H 2 O 100, SiO 2 Sol 33.9, nitric acid solution 0.9, polyvinyl alcohol (polymerization degree 350) solution 47 and water 450. The following synthesis method was adopted: on a magnetic stirrer, heated at 60°C, Ca(NO 3 ) 2 4H 2 Add O into water, heat and stir for 20 minutes until completely dissolved; adjust the pH of the solution to 2.2 with nitric acid solution, add SiO 2 Heat and stir the sol for 20 minutes until it is completely dissolved; adjust the heating temperature of the magnetic stirrer to 90°C, add polyvinyl alcohol solution, heat and stir for 20 minutes until it is evenly mixed; the obtained uniformly mixed sol solution continues to stir and heat for 3 hours, and the water evaporates continuously to form a gel precursor body; put the gel precursor in an oven at 150°C, dry it for 24 hours, grind it and store it in a ...

Embodiment 2

[0030] Embodiment 2, a kind of synthetic tricalcium silicate (C 3 S) the method of single mineral, its raw material weight ratio is: Ca(NO 3 ) 2 4H 2O 100, SiO 2 Sol 33.9, nitric acid solution 1.0, polyvinyl alcohol (polymerization degree 500) solution 70 and water 480. The following synthesis method was adopted: on a magnetic stirrer, heated at 50°C, Ca(NO 3 ) 2 4H 2 Add O into water, heat and stir for 30 minutes until completely dissolved; adjust the pH value of the solution to 2.1 with nitric acid solution, add SiO 2 Heat and stir the sol for 30 minutes until it is completely dissolved; adjust the heating temperature of the magnetic stirrer to 80°C, add polyvinyl alcohol solution, heat and stir for 30 minutes until it is evenly mixed; the obtained uniformly mixed sol solution continues to stir and heat for 5 hours, and the water evaporates continuously to form a gel precursor body; put the gel precursor in an oven at 150°C, dry it for 24 hours, grind it and store it ...

Embodiment 3

[0031] Embodiment 3, a kind of synthesis tricalcium silicate (C 3 S) the method of single mineral, its raw material weight ratio is: Ca(NO 3 ) 2 4H 2 O 100, SiO 2 Sol 33.9, nitric acid solution 1.1, polyvinyl alcohol (polymerization degree 650) solution 100 and water 520. The following synthesis method was adopted: on a magnetic stirrer, heated at 53°C, Ca(NO 3 ) 2 4H 2 Add O into water, heat and stir for 28min until completely dissolved; adjust the pH value of the solution to 2.0 with nitric acid solution, add SiO 2 Heat and stir the sol for 28 minutes until completely dissolved; adjust the heating temperature of the magnetic stirrer to 83°C, add polyvinyl alcohol solution, heat and stir for 28 minutes until the mixture is uniform; the obtained uniformly mixed sol solution continues to stir and heat for 4.5 hours, and the water evaporates continuously to form a gel Precursor; put the gel precursor in an oven at 150°C, dry it for 24 hours, grind it and store it in a des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com