Method for preparing high-performance fuel oil by adopting mesoporous alkaline carbon materials to carry out catalytic cracking on grease

A catalytic cracking and mesoporous carbon technology, applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, physical/chemical process catalysts, etc., can solve problems such as instability, high yield of cracked oil, etc., to achieve wide adaptability and load The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

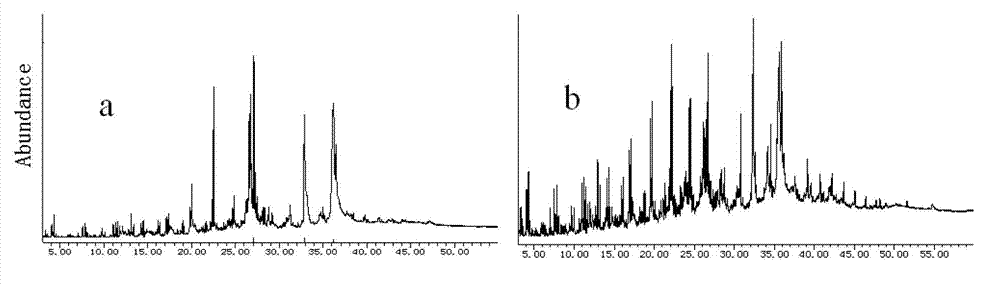

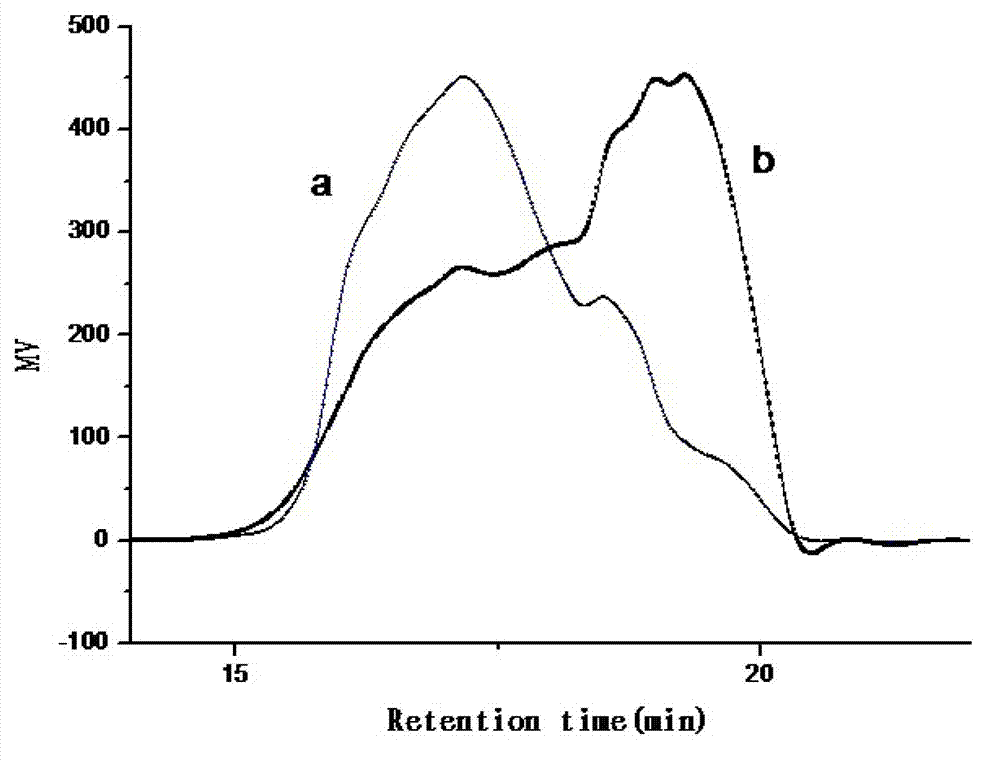

Embodiment 1

[0042] Dissolve 1 g of mesoporous molecular sieve SBA-15 (hard template agent) in 11 mL of distilled water, add 1.25 g of sucrose and 7.2 mL of 0.2 mol / L sulfuric acid, and sonicate for 1 h; Evaporate to constant weight, and then preliminarily carbonize at 160 °C for 6 h; grind the preliminarily carbonized product through an 80-mesh sieve, then dissolve it in 11 mL of water, add 0.75 g of sucrose and 4 mL of 0.2 mol / L sulfuric acid again; repeat The process of water evaporation at 90 ℃ and preliminary carbonization at 160 ℃; 2 Under the protection of the tube furnace, put it in a tube furnace at 900 ℃ for 5 h; dissolve the obtained product in HF solution with a volume fraction of 5% and stir for 24 h to remove the hard template agent; centrifuge, wash with distilled water until neutral, and put it in an oven for 60 °C drying to obtain mesoporous carbon supports. Dissolve 0.05 g of potassium carbonate in 10 mL of distilled water; add 1 g of mesoporous carbon support and sonica...

Embodiment 2

[0045] Dissolve 1 g of mesoporous molecular sieve SBA-15 (hard template agent) in 11 mL of distilled water, add 1.25 g of sucrose and 7.2 mL of 0.2 mol / L sulfuric acid, and sonicate for 1 h; Evaporate to constant weight, and then preliminarily carbonize at 160 °C for 6 h; grind the preliminarily carbonized product through an 80-mesh sieve, then dissolve it in 11 mL of water, add 0.75 g of sucrose and 4 mL of 0.2 mol / L sulfuric acid again; repeat The process of water evaporation at 90 ℃ and preliminary carbonization at 160 ℃; 2 Under the protection of the tube furnace, put it in a tube furnace at 900 ℃ for 5 h; dissolve the obtained product in HF solution with a volume fraction of 5% and stir for 24 h to remove the hard template agent; centrifuge, wash with distilled water until neutral, and put it in an oven for 60 °C drying to obtain mesoporous carbon supports. Dissolve 0.05 g of potassium carbonate in 10 mL of distilled water; add 1 g of mesoporous carbon support and sonica...

Embodiment 3

[0048] Dissolve 1 g of mesoporous molecular sieve SBA-15 (hard template agent) in 11 mL of distilled water, add 1.25 g of sucrose and 7.2 mL of 0.2 mol / L sulfuric acid, and sonicate for 1 h; Evaporate to constant weight, and then preliminarily carbonize at 160 °C for 6 h; grind the preliminarily carbonized product through an 80-mesh sieve, then dissolve it in 11 mL of water, add 0.75 g of sucrose and 4 mL of 0.2 mol / L sulfuric acid again; repeat The process of water evaporation at 90 ℃ and preliminary carbonization at 160 ℃; 2 Under the protection of the tube furnace, put it in a tube furnace at 900 ℃ for 5 h; dissolve the obtained product in HF solution with a volume fraction of 5% and stir for 24 h to remove the hard template agent; centrifuge, wash with distilled water until neutral, and put it in an oven for 60 °C drying to obtain mesoporous carbon supports. Dissolve 0.05 g of potassium carbonate in 10 mL of distilled water; add 1 g of mesoporous carbon support and sonica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com