Method for preparing high-performance fuel oil by adopting mesoporous alkaline carbon materials to carry out catalytic cracking on grease

A catalytic cracking, mesoporous carbon technology, applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, catalysts for physical/chemical processes, etc. , The effect of the load method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

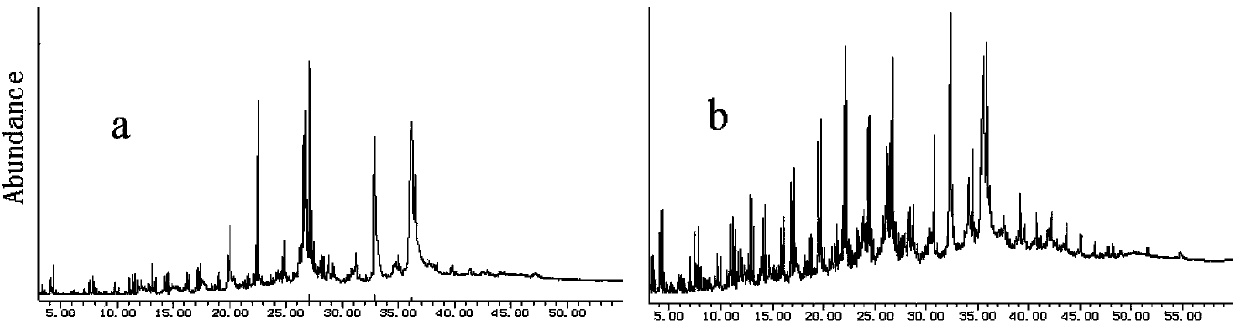

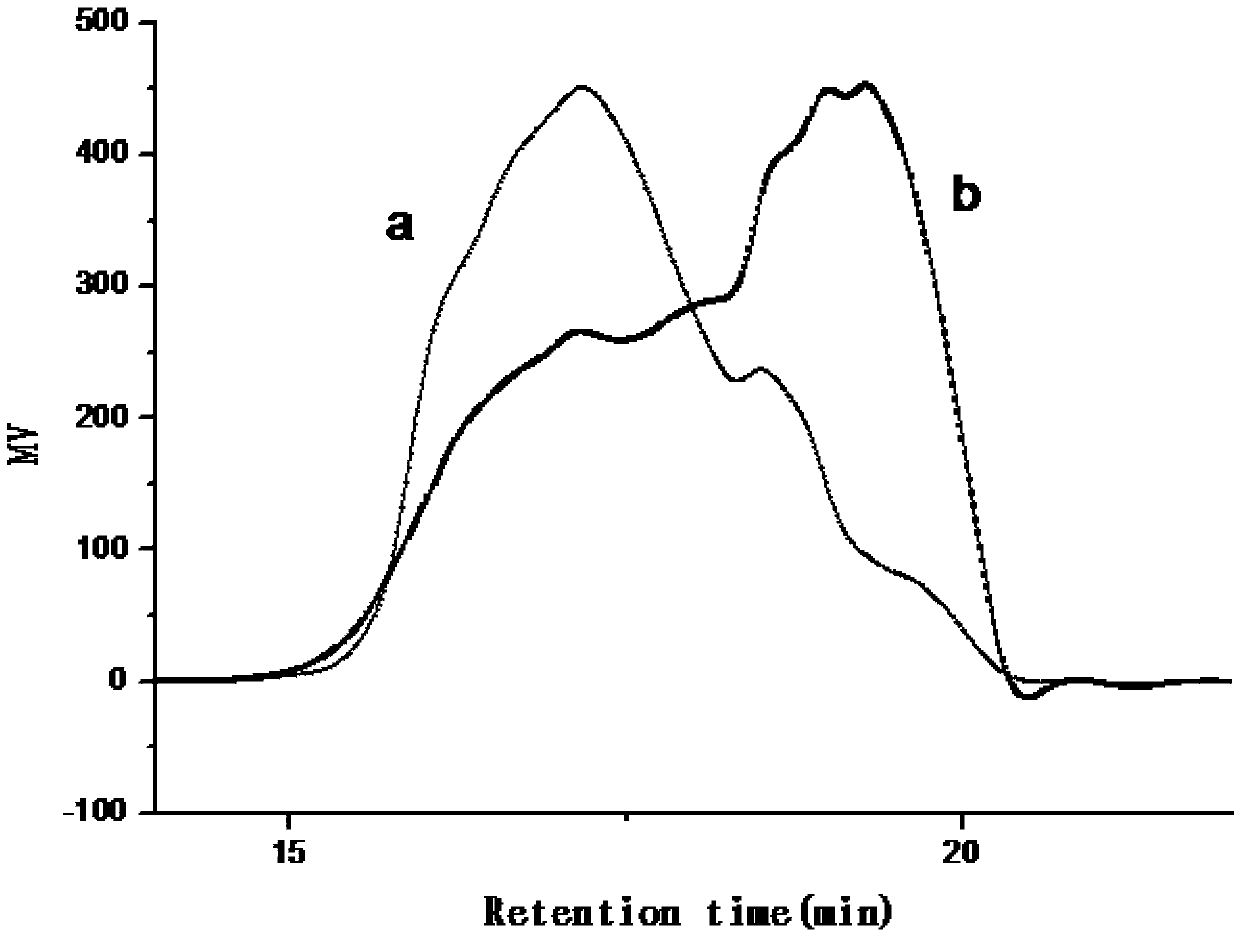

Embodiment 1

[0036] Dissolve 1g of mesoporous molecular sieve SBA-15 (hard templating agent) in 11mL of distilled water, add 1.25g of sucrose and 7.2mL of 0.2mol / L sulfuric acid, sonicate for 1h; evaporate the water to constant temperature at 90°C and then carbonized initially at 160°C for 6 hours; the initially carbonized product was ground through an 80-mesh sieve, then dissolved in 11 mL of water, and 0.75 g of sucrose and 4 mL of 0.2 mol / L sulfuric acid were added again; water evaporation at 90°C and 160 ℃ initial carbonization process; in N 2 Under the protection of the tube furnace, put it in a tube furnace at 900°C for 5h; dissolve the obtained product in a HF solution with a volume fraction of 5% and stir for 24h to remove the hard template agent; centrifuge, wash with distilled water until neutral, and dry in an oven at 60°C A mesoporous carbon support was obtained. Dissolve 0.05g of potassium carbonate in 10mL of distilled water; add 1g of mesoporous carbon carrier, and sonicate...

Embodiment 2

[0038] Dissolve 1g of mesoporous molecular sieve SBA-15 (hard templating agent) in 11mL of distilled water, add 1.25g of sucrose and 7.2mL of 0.2mol / L sulfuric acid, sonicate for 1h; evaporate the water to constant temperature at 90°C and then carbonized initially at 160°C for 6 hours; the initially carbonized product was ground through an 80-mesh sieve, then dissolved in 11 mL of water, and 0.75 g of sucrose and 4 mL of 0.2 mol / L sulfuric acid were added again; water evaporation at 90°C and 160 ℃ initial carbonization process; in N 2 Under the protection of the tube furnace, put it in a tube furnace at 900°C for 5h; dissolve the obtained product in a HF solution with a volume fraction of 5% and stir for 24h to remove the hard template agent; centrifuge, wash with distilled water until neutral, and dry in an oven at 60°C A mesoporous carbon support was obtained. Dissolve 0.05g of potassium carbonate in 10mL of distilled water; add 1g of mesoporous carbon carrier, and sonicate...

Embodiment 3

[0040] Dissolve 1g of mesoporous molecular sieve SBA-15 (hard templating agent) in 11mL of distilled water, add 1.25g of sucrose and 7.2mL of 0.2mol / L sulfuric acid, sonicate for 1h; evaporate the water to constant temperature at 90°C and then carbonized initially at 160°C for 6 hours; the initially carbonized product was ground through an 80-mesh sieve, then dissolved in 11 mL of water, and 0.75 g of sucrose and 4 mL of 0.2 mol / L sulfuric acid were added again; water evaporation at 90°C and 160 ℃ initial carbonization process; in N 2Under the protection of the tube furnace, put it in a tube furnace at 900°C for 5h; dissolve the obtained product in a HF solution with a volume fraction of 5% and stir for 24h to remove the hard template agent; centrifuge, wash with distilled water until neutral, and dry in an oven at 60°C A mesoporous carbon support was obtained. Dissolve 0.05g of potassium carbonate in 10mL of distilled water; add 1g of mesoporous carbon carrier, and sonicate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com