Preparation method of anatase phase mesohole nano-titanium dioxide powder

A technology of nano-titanium dioxide and anatase phase, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of reducing the specific surface area of nano-materials, having no catalytic activity, and the collapse of porous structures, so as to achieve broad application prospects and low energy consumption. And the effect of low cost and favorable low temperature formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation process of the present invention is as follows:

[0026]

[0027] The basic steps are: weigh titanium sulfate and alkyl primary amine hydrochloride, add ethanol under magnetic stirring, and then add water; secondly, adjust the pH of the solution, and age at room temperature; thirdly, seal the reaction vessel with adhesive tape, 100-110 Continue to age at ℃; the fourth is to remove the template agent with saturated ethanol solution of sodium chloride after centrifugation and washing; the fifth is to heat treat at different temperatures after washing and drying.

[0028] The specific implementation method of preparing a kind of anatase phase mesoporous nano titanium dioxide powder is as follows:

[0029] (1) Weigh 1.6-1.8g of titanium sulfate [Ti(SO 4 ) 2 ] and 1.1-1.3g alkylamine hydrochloride (or by Ti: primary amine molar ratio is 2: 1 or 1: 1, take dodecylamine hydrochloride or stearylamine hydrochloride respectively);

[0030] (2) Place the abov...

Embodiment 1

[0038] Embodiment 1: take by weighing 1.7600g Ti(SO 4 ) 2 and 1.2172g of dodecylamine hydrochloride, add 20ml of ethanol under magnetic stirring, after stirring for 10min, then slowly add 20ml of secondary water, and stir for 30min. Aging at room temperature for 48 hours. Then it was sealed with adhesive tape and aged at 100°C for 48 hours. After cooling, centrifuge and wash twice with water until 2% barium nitrate [Ba(NO 3 ) 2 ] detected to no SO 4 2- , washed with ethanol and dried. Remove the template agent with saturated ethanol solution of sodium chloride, wash with secondary water and ethanol again, and dry.

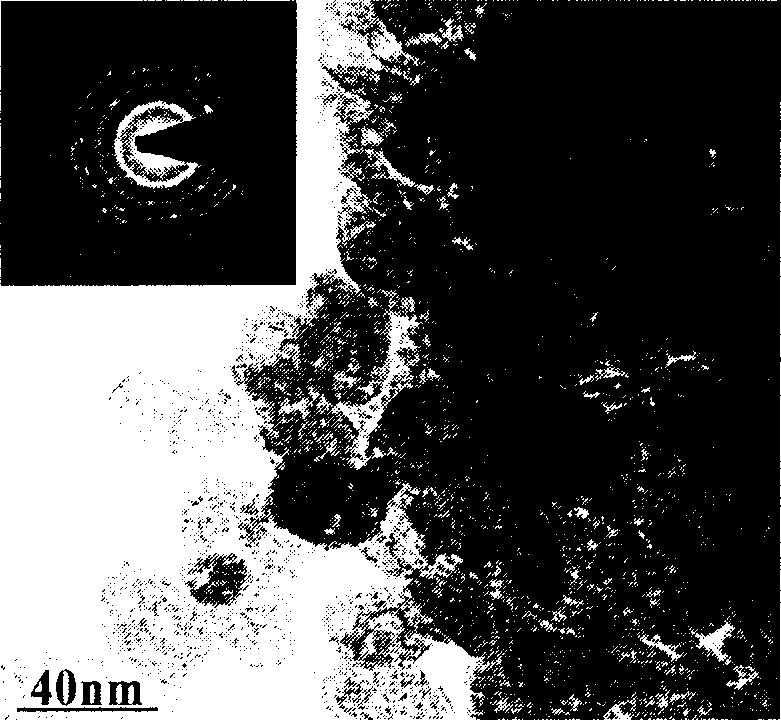

[0039] Calcined at 300°C for 2 hours, the morphology of the obtained product is shown in figure 1 with figure 2 , the particle distribution is relatively uniform, the average particle size is 25nm, the average pore size is 3.3nm, the average grain size is 3.9nm, and the specific surface area is 212m 2 / g, the degree of crystallization of the pore wall is...

Embodiment 2

[0040] Embodiment 2: take by weighing 1.7600g Ti(SO 4 ) 2 and 3.3605g of octadecylamine hydrochloride, add 20ml of ethanol under magnetic stirring, after stirring for 10min, slowly add 20ml of secondary water, and stir for 30min. Aging at room temperature for 48 hours. Then it was sealed with adhesive tape and aged at 100°C for 48 hours. After cooling, centrifuge and wash twice with water until 2% barium nitrate [Ba(NO 3 ) 2 ] detected to no SO 4 2- , washed with ethanol and dried. Remove the template agent with saturated ethanol solution of sodium chloride, wash with water and ethanol twice, and dry.

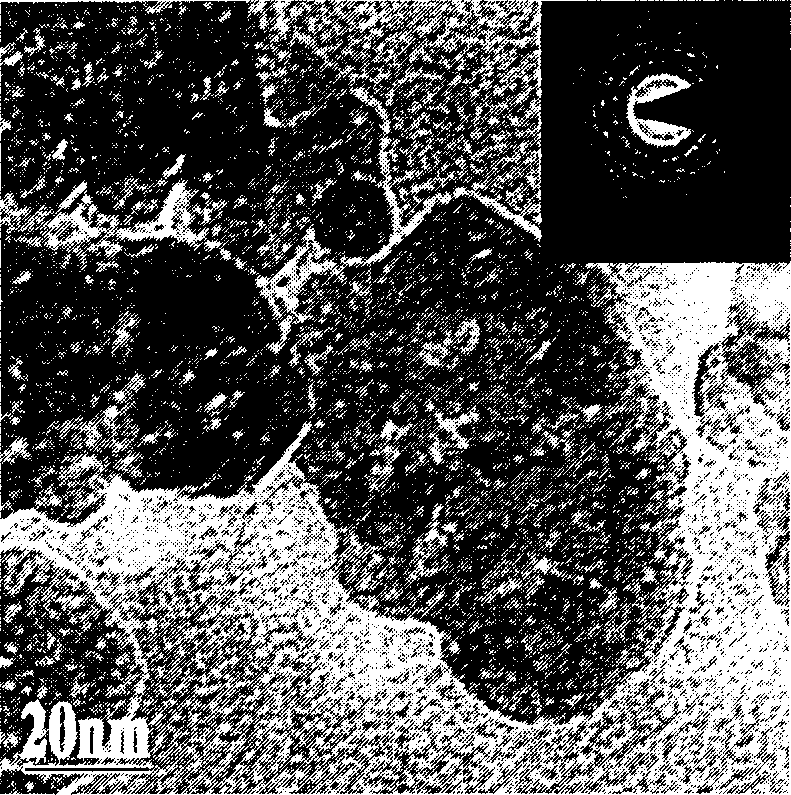

[0041] Calcined at 300°C for 2 hours, the particle distribution of the product obtained is relatively uniform, the average particle size is 38.3nm, the average pore size is 5.0nm, the average grain size is 3.4nm, and the specific surface area is 296.6m 2 / g, the degree of crystallization of the pore wall is higher. Calcined at 400°C for 2 hours, the particle distributi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com