Up-conversion nanocrystalline zeolite composite material as well as preparation method and application thereof

A composite material and nanocrystal technology, which is applied in the field of upconversion nanocrystal-zeolite composite material and its preparation, can solve the problems of limited application, difficulty in high-intensity upconversion luminescence, etc., and achieves simple operation, reduced non-radiative transition, and high efficiency. Effect of upconverting luminescence properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

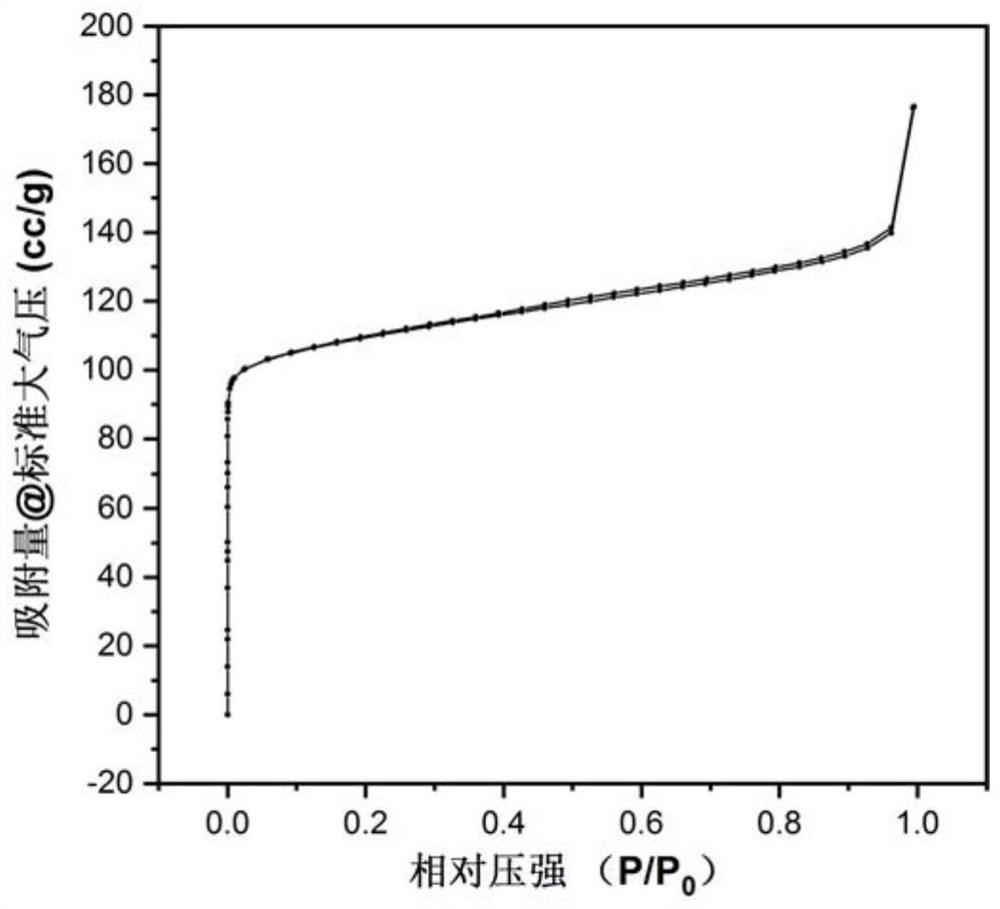

[0037] (1) Take 0.8mmol YCl of rare earth compound 3 ·6H 2 O, 0.02mmol ErCl 3 ·6H 2 O and 0.18 mmol YbCl 3 ·6H 2 O, added to the mixed solution of 6mL oleic acid and 15mL 1-octadecene, heated and stirred at 160°C for 40 minutes under an argon atmosphere, after the rare earth was dissolved, stop heating and naturally cool to room temperature;

[0038](2) 0.3g FAU Y-type zeolite powder was added to the solution obtained in (1), and stirred at room temperature for 1.5 hours;

[0039] (3) Dissolve 2.5mmol sodium oleate and 4mmol ammonium fluoride in 10mL methanol respectively, and drop the obtained two methanol solutions into the solution obtained in (2) successively, and stir and heat at 65°C for 50min, until the methanol is exhausted;

[0040] (4) Heat the solution obtained in (3) at 280° C. for 30 minutes under an argon atmosphere, and then cool to room temperature;

[0041] (5) Centrifuge the solution obtained in (4), disperse the solid obtained by centrifugation with 1...

Embodiment 2

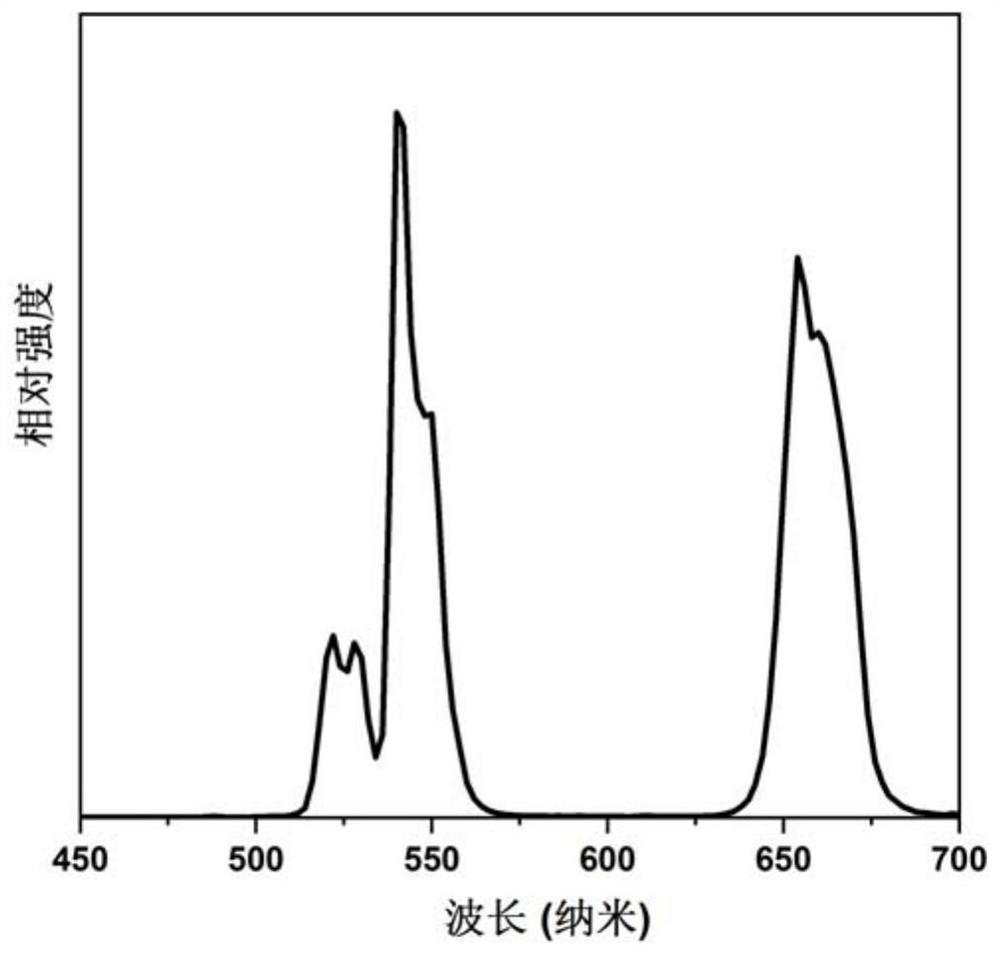

[0047] (1) Take the rare earth compound 0.78mmol YCl 3 ·6H 2 O, 0.02mmol HoCl 3 ·6H 2 O and 0.20 mmol YbCl 3 ·6H 2 O, added to the mixed solution of 6mL oleic acid and 15mL 1-octadecene, heated and stirred at 160°C for 40 minutes under an argon atmosphere, after the rare earth was dissolved, stop heating and naturally cool to room temperature;

[0048] (2) 0.2g FAU X type zeolite powder is added to the solution obtained in (1), and stirred at room temperature for 1.5 hours;

[0049] (3) Dissolve 2.5mmol sodium oleate and 4mmol ammonium fluoride in 10mL methanol respectively, and drop the obtained two methanol solutions into the solution obtained in (2) successively, and stir and heat at 65°C for 50min, until the methanol is exhausted;

[0050] (4) Heat the solution obtained in (3) at 280° C. for 30 minutes under an argon atmosphere, and then cool to room temperature;

[0051] (5) Centrifuge the solution obtained in (4), disperse the solid obtained by centrifugation with...

Embodiment 3

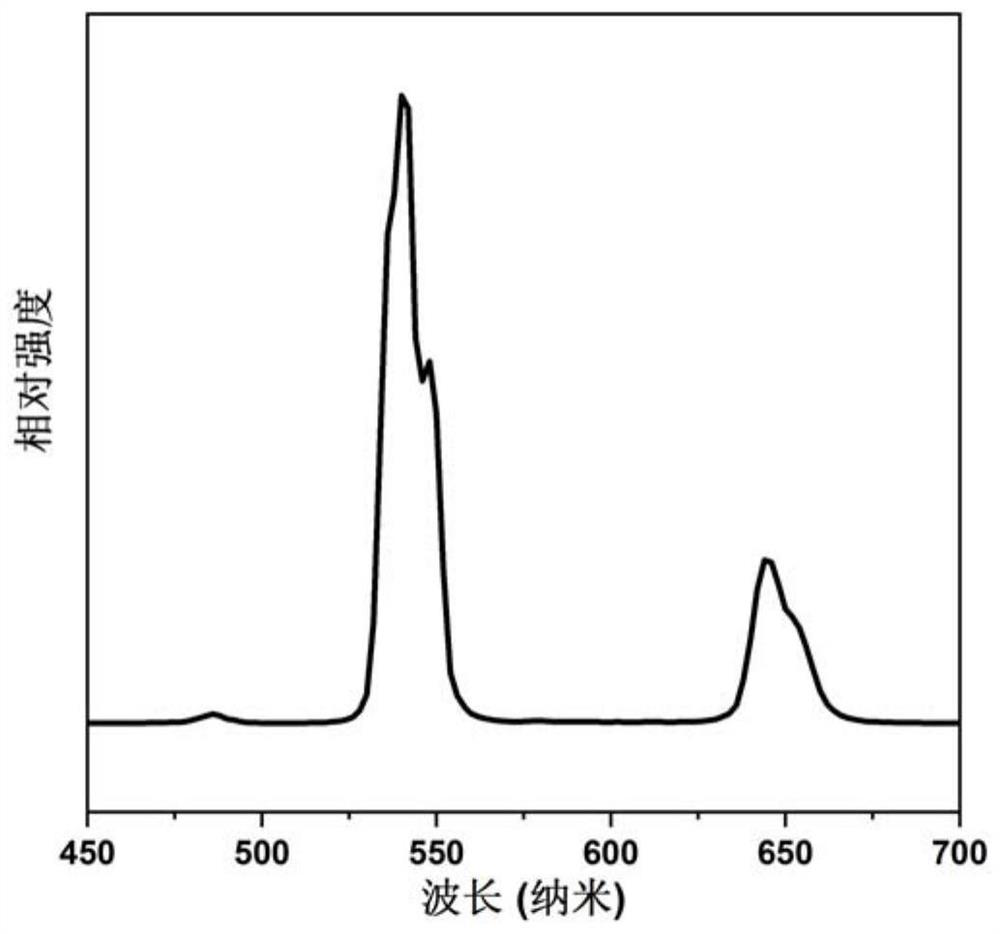

[0056] (1) Take the rare earth compound 0.67mmol YCl 3 ·6H 2 O, 0.03mmol TmCl 3 ·6H 2 O and 0.30 mmol YbCl 3 ·6H 2 O, added to the mixed solution of 6mL oleic acid and 15mL 1-octadecene, heated and stirred at 160°C for 40 minutes under an argon atmosphere, after the rare earth was dissolved, stop heating and naturally cool to room temperature;

[0057] (2) 0.1g FAU Y-type zeolite powder was added to the solution obtained in (1), and stirred at room temperature for 1.5 hours;

[0058] (3) Dissolve 2.5mmol sodium oleate and 4mmol ammonium fluoride in 10mL methanol respectively, and drop the obtained two methanol solutions into the solution obtained in (2) successively, and stir and heat at 65°C for 50min, until the methanol is exhausted;

[0059] (4) Heat the solution obtained in (3) at 280° C. for 30 minutes under an argon atmosphere, and then cool to room temperature;

[0060] (5) Centrifuge the solution obtained in (4), disperse the solid obtained by centrifugation wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com