Multi-frequency ultrasonic radiation overflow groove continuous biodiesel production device

A multi-frequency ultrasonic and biodiesel technology, which is applied in the fields of biofuel, petroleum industry, and fat production, can solve the problems of unstable product quality, high energy consumption in the production process, and low mass transfer rate, so as to improve the rate of transesterification reaction , Improve the conversion rate, and evenly distribute the sound intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

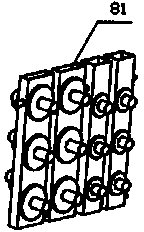

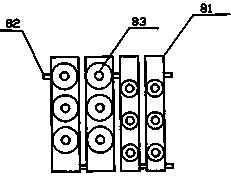

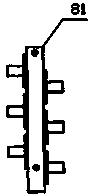

[0036] Such as figure 1As shown, a multi-frequency ultrasonic radiation overflow tank continuous biodiesel production device includes a raw material oil tank 1, a methanol-catalyst storage tank 3, a pre-esterification reactor 5, a step-by-step overflow multi-frequency ultrasonic reactor 8, Glycerin separation tank 11, glycerin tank 12, product washing tank 13, waste water tank 14, crude methyl ester storage tank 15, hot water tank 16, fractionation device 17.

[0037] The raw material oil tank 1 and the methanol-catalyst storage tank 3 are respectively connected to the inlet of the pre-esterification reactor 5 through pipelines. The outlet of the pre-esterification reactor 5 is connected to the first stage of the step-by-step overflow multi-frequency ultrasonic reactor 8 through pipelines. Inlet connection for ultrasonic reaction tank. The outlet of the fourth-stage ultrasonic reaction tank of the stepwise overflow multi-frequency ultrasonic reactor 8 is connected to one end ...

Embodiment 2

[0048] This embodiment is the same as Embodiment 1 except for the subordinate features: this embodiment is mainly aimed at the production process of biodiesel from feedstock oil with moderate acid value.

[0049] For raw material oil with moderate acid value, it can be mixed with concentrated H 2 SO 4 The catalyst is used to catalyze the raw oil to carry out the pre-esterification reaction, and then the potassium hydroxide is used as the catalyst to catalyze the raw oil to carry out the transesterification reaction to prepare biodiesel.

[0050] Raw oil and methanol-concentrated H in raw oil tank 1 and methanol-catalyst tank 3 2 SO 4 The flow of the solution is controlled by the first rotor flow meter 2 and the second rotor flow rate 4 respectively, and flows into the pre-esterification reaction kettle according to a certain alcohol-oil ratio to carry out the pre-esterification reaction; after the acid value drops below 2mgKOH / g, add an appropriate amount of alkali Neutr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com