Natural pork flavor

A pork flavor and natural technology, applied in the field of flavor, can solve the problems of easy-to-produce burnt-flavor substances, complex operating conditions, long reaction time, etc., and achieve the effect of avoiding burnt-flavor phenomenon, simple operating conditions, and realistic meat texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A preparation method of natural pork essence, comprising steps:

[0022] 1), prepare pork reaction flavor base

[0023] Pork reaction fragrance base is made of the following raw materials: pork (fat, lean): 10Kg; lard: 3Kg; hydrolyzed vegetable protein (HVP): 5Kg; cysteine hydrochloride: 1Kg; glutamic acid: 0.5Kg; Glycine: 0.6Kg; Furanone: 0.2Kg; Papain: 0.08Kg; Vitamin B 1 : 1Kg; vitamin C: 0.2Kg; salt: 10Kg; propylene glycol: 2Kg; cinnamon powder: 3Kg; nutmeg oil: 0.2Kg; cold-pressed ginger oil: 0.5Kg; pepper oil: 0.5Kg; Oil: 0.2Kg, first put pork, vitamin B 1 , vitamin C, and papain were stirred and mixed at 60°C for 30 minutes, and then other remaining reaction materials were added to the obtained enzymolysis solution, and the Maillard reaction was carried out at 105°C for 20 minutes to obtain pork-reactive fragrance base;

[0024] 2), prepare meat flavor base

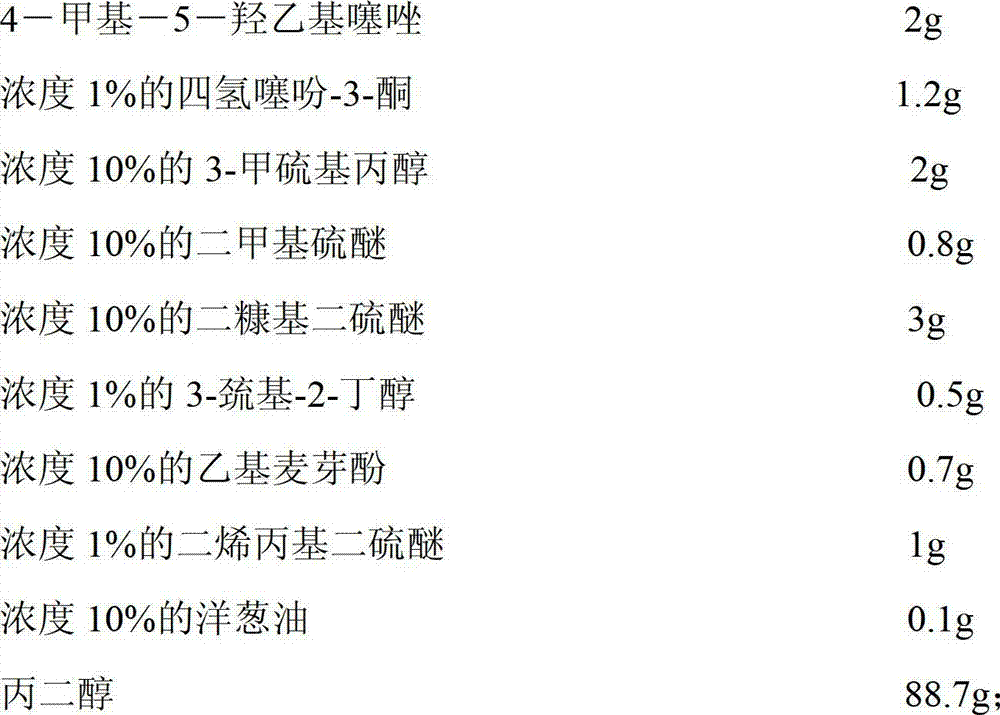

[0025] The meat flavor base is obtained by mixing the following materials evenly:

[0026]

[0...

Embodiment 2

[0030] A preparation method of natural pork essence, comprising steps:

[0031] 1), prepare pork reaction flavor base

[0032] Pork reaction fragrance base is made of the following raw materials: pork (fat, lean): 12Kg; lard: 2Kg; hydrolyzed vegetable protein (HVP): 6Kg; cysteine hydrochloride: 1.2Kg; glutamic acid: 0.6Kg ;Glycine: 0.5Kg; Furanone: 0.3Kg; Papain: 0.1Kg; Vitamin B 1 : 0.8Kg; vitamin C: 0.2Kg; salt: 10Kg; propylene glycol: 1Kg; cinnamon powder: 2Kg; nutmeg oil: 0.3Kg; cold-pressed ginger oil: 0.5Kg; Scallion oil: 0.3Kg, first put pork, vitamin B 1 , vitamin C and papain were stirred and mixed at 50°C for 40 minutes, and then other remaining reaction raw materials were added to the obtained enzymolysis liquid, and the Maillard reaction was carried out at 100°C for 30 minutes to obtain pork-reactive fragrance base;

[0033] 2), prepare meat flavor base

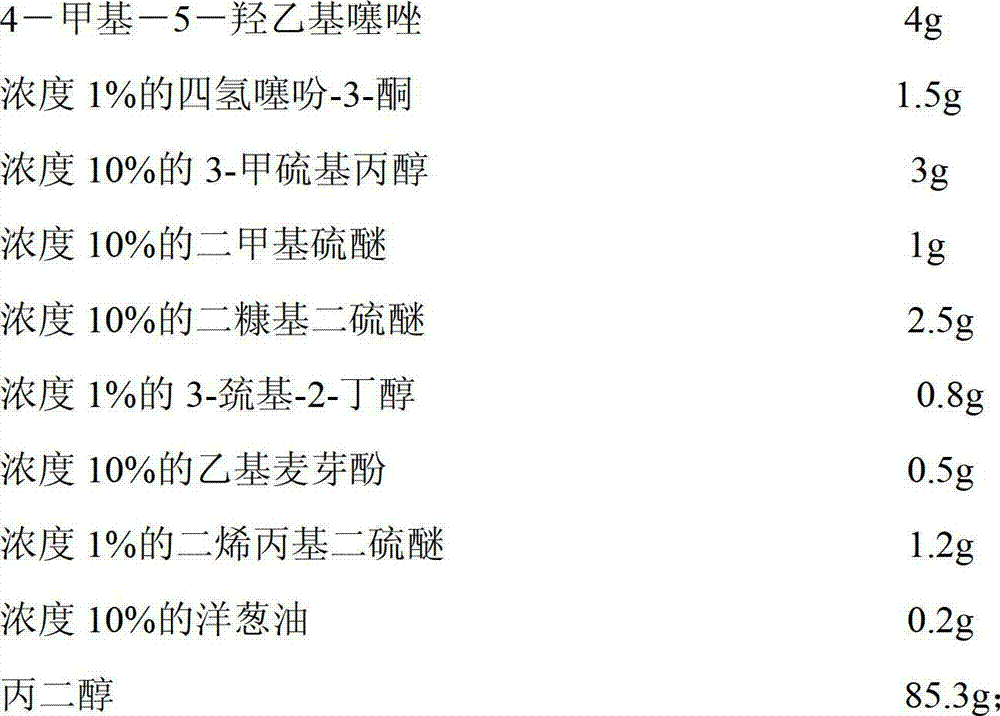

[0034] The meat flavor base is obtained by mixing the following materials evenly:

[0035]

[0036] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com