Far-infrared electrostatic treatment film

A treatment film and far-infrared technology, applied in the field of medical devices, can solve the problems of insignificant treatment effect, small symptomatic treatment range, etc., and achieve good rehabilitation effect, good treatment effect, and the effect of promoting the increase of permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

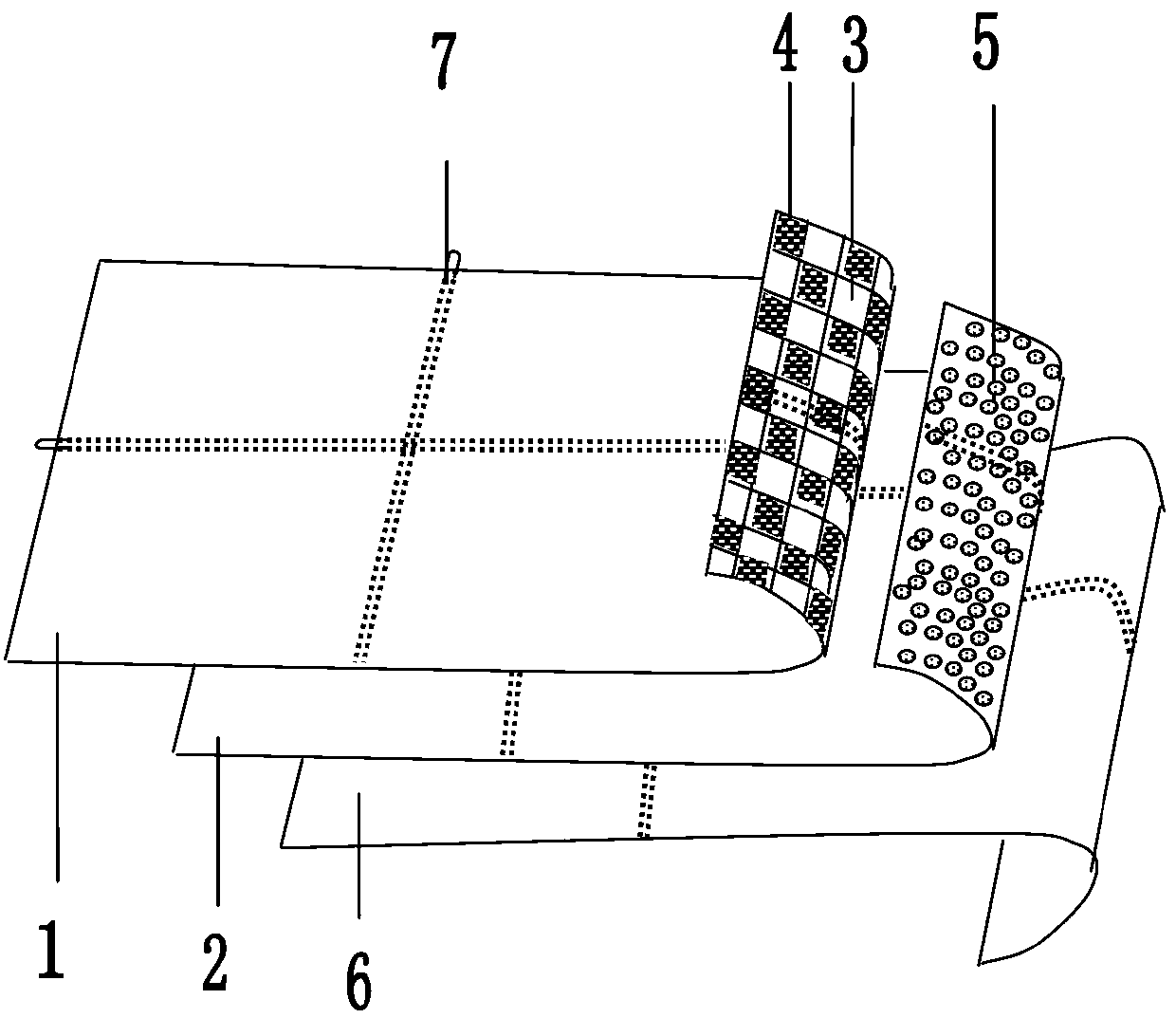

[0021] Example 1, the far-infrared electrostatic bone wound treatment film, the polytetrafluoroethylene plastic and the perfluoroethylene propylene plastic are processed and refined according to the ratio of 0.6:0.4 to make a microporous film, the film thickness is 0.2mm, and the film is processed into There are two kinds of sheet A and sheet B. A square groove is set on the sheet A, and it is processed into an electret electrostatic film after being treated by corona method or breakdown electret technology. The surface potential value of the positive electrode is 1500V. The infrared wavelength is 15mm, and the infrared normal total emission rate is ≥80%. Cut the electret electrostatic film A sheet (1) and the electret electrostatic film B sheet (2) into standard materials, and place the far-infrared ceramic powder (4) and adhesive on the electret electrostatic film A sheet (1) In the grid groove (3), the electret electrostatic film B (2) is covered, and the electret electrost...

Embodiment 2

[0022] Example 2, far-infrared electrostatic aseptic inflammation treatment film, the polytetrafluoroethylene plastic and perfluoroethylene propylene plastic are processed and refined according to the ratio of 0.4:0.6 to make a microporous film, the film thickness is 0.15mm, and the film It is processed into two kinds of A sheet and B sheet. A square groove is set on the A sheet, and it is processed into an electret electrostatic film after being treated by corona method or breakdown electret technology. The surface potential value of the positive electrode is 1000V. Far-infrared ceramic The infrared wavelength of the powder is 10mm, and the infrared normal total emissivity is ≥80%. Cut the electret electrostatic film A sheet (1) and the electret electrostatic film B sheet (2) into standard materials, and place the far-infrared ceramic powder (4) and adhesive on the electret electrostatic film A sheet (1) In the grid groove (3), the electret electrostatic film B (2) is covered...

Embodiment 3

[0023] Embodiment 3, the far-infrared electrostatic treatment film for hypertension, the polytetrafluoroethylene plastic and the perfluoroethylene propylene plastic are processed and refined according to the ratio of 0.7:0.3 to make a microporous film, the film thickness is 0.15mm, and the film is processed into There are two types of sheet A and sheet B. A square groove is set on the sheet A, and it is processed into an electret electrostatic film after being treated by corona method or breakdown electret technology. The surface potential value of the negative electrode is 600V, and the far-infrared ceramic powder ( 4) The infrared wavelength is 8mm, and the infrared normal total emissivity is ≥80%. Cut the electret electrostatic film A sheet (1) and the electret electrostatic film B sheet (2) into standard materials, and place the far-infrared ceramic powder (4) and adhesive on the electret electrostatic film A sheet (1) In the grid groove, the electret electrostatic film B ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com