Polyvinylidene fluoride film capable of responding to visible light and preparation method of polyvinylidene fluoride film

A polyvinylidene fluoride film and a polyvinylidene fluoride technology are applied in the field of visible light responsive polyvinylidene fluoride film and its preparation, which can solve the problems of restricting the practical application of titanium dioxide modified film, achieve good anti-pollution performance and be easy to popularize , the effect of good penetration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

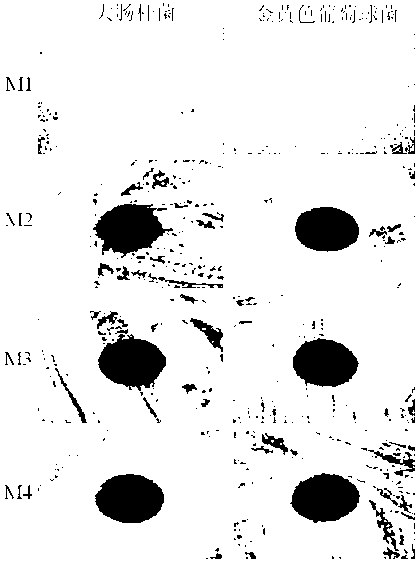

[0023] The preparation method of the visible light-responsive polyvinylidene fluoride film of the present invention comprises the following processes:

[0024] (1) Preparation of titanium dioxide / polyvinylidene fluoride membrane: dissolve titanium dioxide and pore-forming agent in dimethylformamide or dimethylacetamide solvent to prepare a casting solution with a mass fraction of 10-20%, 60- Stir evenly at 70°C; solution cooling, defoaming, scraping film, wherein the composition of the coagulation bath is aqueous solution of dimethylformamide or aqueous solution of dimethylacetamide, the temperature is 20-40°C; cleaning with deionized water and natural drying After drying, a titanium dioxide / polyvinylidene fluoride film was obtained.

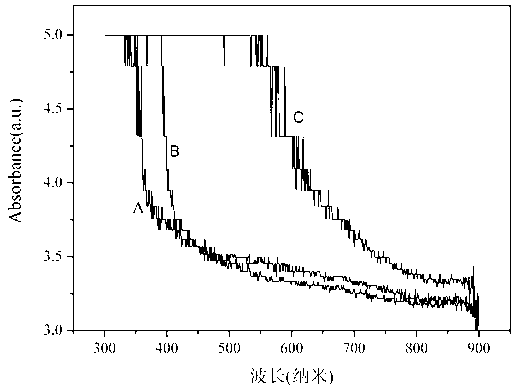

[0025] (2) Preparation of silver / titanium dioxide / polyvinylidene fluoride film: put a certain size of titanium dioxide / polyvinylidene fluoride film into a conical flask filled with silver ion solution, and place it in a dark environment for a pe...

Embodiment 1

[0028] 1) Preparation of titanium dioxide / polyvinylidene fluoride film: take 3.5g PVDF powder, 1.4gTiO 2 and 1.05g of PVP were dissolved in 32ml of N,N-dimethylacetamide (DMAc), dubbed 10 wt. %PVDF casting solution, stirred at 65°C until uniform. The casting solution was cooled, degassed under reduced pressure, and then spread evenly on the non-woven fabric with a scraper with a thickness of 200 μm, and then placed in a coagulation bath (DMAc / H 2 O = 2 / 3, v / v), after the casting solution is solidified, it is fully washed with deionized water, and dried to obtain a titanium dioxide / polyvinylidene fluoride film.

[0029] 2) Preparation of silver / titanium dioxide / polyvinylidene fluoride film: put 2 pieces of titanium dioxide / polyvinylidene fluoride film (3cm×3cm) into a conical flask filled with silver nitrate solution (25ml, 0.05M) and place in a dark place 10min. Thereafter, the film was taken out from the Erlenmeyer flask and irradiated under a UV lamp (20w) for 10 min, an...

Embodiment 2

[0032] 1) Preparation of titanium dioxide / polyvinylidene fluoride film: same as Step 1 of Example 1.

[0033] 2) Preparation of silver / titanium dioxide / polyvinylidene fluoride film: Put 2 pieces of titanium dioxide / polyvinylidene fluoride film (3cm×3cm) into a conical flask filled with silver nitrate solution (25ml, 0.05M) and place in a dark place 20min. Thereafter, the film was taken out from the Erlenmeyer flask and irradiated under a UV lamp (20w) for 10 min, and the distance between the film and the UV light source was set at 10 cm. The membrane was immersed in deionized water for 12 h, and then dried in a vacuum oven at 35 °C.

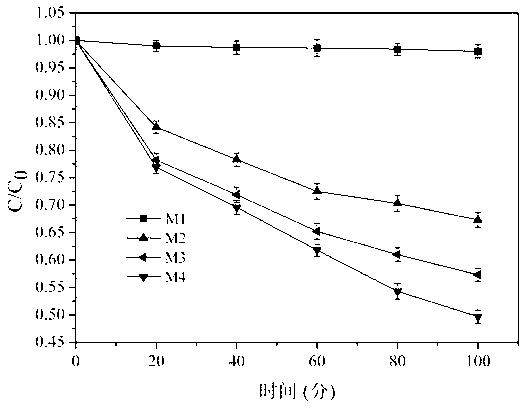

[0034] Visible light (light source: 18w) catalytic degradation of methylene blue (MB) experiments confirmed that after 100min irradiation, the degradation rate of the PVDF membrane (M1) without surface modification can be ignored, while the degradation rate of the PVDF membrane (M3) prepared in this example rate reached 43%. Visible light (lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com